Revolutionizing Welding: The Power of Laser Welding Machines

INDUSTRIAL NEWS

In recent years, the manufacturing industry has witnessed significant advancements in welding technology. One such innovation that has gained immense popularity is the laser welding machine. This cutting-edge technology has revolutionized the welding process, offering numerous benefits over traditional welding methods. In this blog, we will explore the world of laser welding machines and delve into the reasons behind their growing popularity.

1. What is Laser Welding?

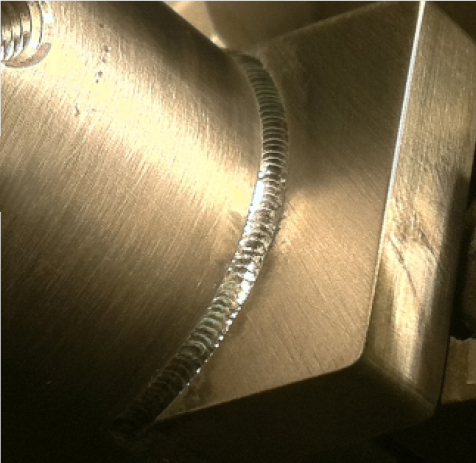

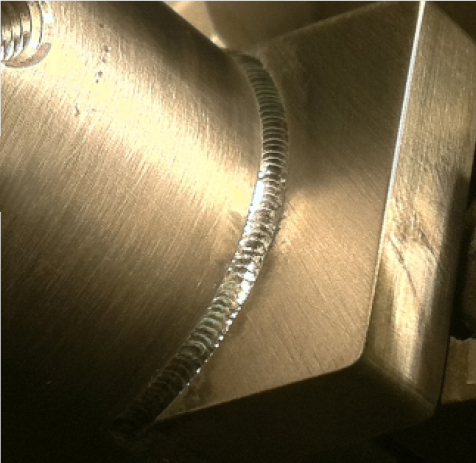

Laser welding is a welding technique that utilizes a high-powered laser beam to join materials together. Unlike traditional welding methods that rely on heat generated by an electric arc or flame, laser welding uses a concentrated beam of light to create a highly focused heat source. This precise and controlled heat application results in superior weld quality and minimal distortion.

2. Advantages of Laser Welding Machines:

a. Precision: Laser welding machines offer exceptional precision and accuracy. The focused laser beam allows for pinpoint welding, making it ideal for intricate and delicate welding tasks.

b. Speed: Laser welding is significantly faster than traditional welding methods. The concentrated heat source enables rapid and efficient welding, reducing production time and increasing productivity.

c. Versatility: Laser welding machines can be used to join a wide range of materials, including metals, plastics, and even dissimilar materials. This versatility makes laser welding suitable for various industries, such as automotive, aerospace, and electronics.

d. Minimal Heat Affected Zone (HAZ): Laser welding produces a small heat-affected zone, resulting in minimal distortion and reduced material damage. This is particularly beneficial for welding sensitive materials or components with tight tolerances.

e. Cost-effective: Although laser welding machines have a higher upfront cost, they offer long-term cost savings. The precise heat application reduces the need for post-welding treatments, such as grinding or polishing, thereby reducing labor costs.

3. Applications of Laser Welding Machines:

a. Automotive Industry: Laser welding is widely used in the automotive industry for joining body panels, chassis components, and exhaust systems. The precise and high-speed welding process ensures strong and durable welds, improving vehicle safety and performance.

b. Medical Industry: Laser welding machines are commonly employed in the medical sector for joining delicate and small medical devices, such as surgical instruments and implants. The precise and non-contact nature of laser welding minimizes the risk of contamination and damage to sensitive components.

c. Electronics Industry: Laser welding is crucial in the production of electronic devices, such as smartphones and computers. It enables the precise and reliable joining of delicate electronic components, ensuring optimal performance and longevity.

Laser welding machines have revolutionized the welding industry, offering unprecedented precision, speed, and versatility. The numerous advantages, including minimal distortion, reduced material damage, and cost-effectiveness, make laser welding an ideal choice for various applications. As technology continues to advance, it is certain that laser welding machines will play an increasingly significant role in the manufacturing industry, driving innovation and improving product quality.