What is a CO2 Laser Cutting Machine?

INDUSTRIAL NEWS

What is a CO2 Laser Cutting Machine?

A CO2 laser cutting machine is a type of industrial laser cutter that utilizes a carbon dioxide gas mixture as the laser medium to cut through a wide variety of materials. This technology has revolutionized the manufacturing industry by offering precise, efficient, and versatile cutting capabilities.

Principles of CO2 Laser Cutting

Laser Generation:

The laser is created by exciting a mixture of carbon dioxide (CO2), nitrogen (N2), and helium (He) gases with an electrical discharge.

The excited CO2 molecules emit light at a wavelength of around 10.6 micrometers, which is in the infrared range.

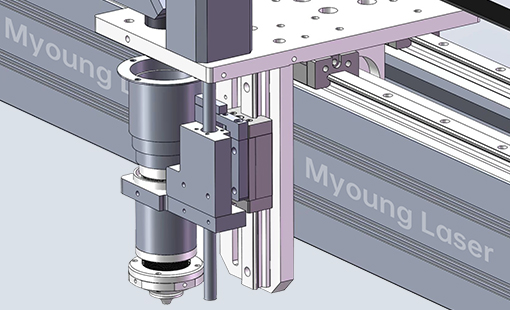

Beam Delivery:

The emitted laser light is amplified and directed through a series of mirrors or optical fibers to the cutting head.

A focusing lens concentrates the laser beam into a small, intense spot on the material surface.

Material Interaction:

The focused laser beam heats the material to its melting, vaporization, or ignition point.

An assist gas, such as oxygen, nitrogen, or air, is used to blow away the molten or vaporized material, resulting in a precise cut.

Features of CO2 Laser Cutting Machines

High Precision: Capable of producing detailed and intricate cuts with minimal kerf (cut width) and high repeatability.

Smooth Edges: Provides clean, smooth cutting edges, often eliminating the need for additional finishing processes.

Versatility: Can cut a wide range of materials, including metals, plastics, wood, textiles, and composites.

Non-contact Process: As the laser cutting is a non-contact process, there is no mechanical force applied to the workpiece, reducing the risk of distortion.

Automation: Easily integrated with computer numerical control (CNC) systems for automated and precise control of the cutting process.

Types of CO2 Laser Cutting

Melt and Blow:

The laser beam heats the material until it melts.

A high-pressure, non-reactive gas (like nitrogen) blows the molten material out of the cutting area.

This method allows for lower energy use to achieve the same cut depth.

Reactive Cutting:

Used on materials that oxidize easily, such as steel or titanium.

The laser heats a localized area, and a high-pressure stream of oxygen is directed onto it.

The oxygen causes the metal to oxidize and burn, and the oxides are blown from the cut by the oxygen stream.

Vaporization Cutting:

Relies solely on the heat from the laser beam to sublimate the material directly from a solid to a gas phase.

Suitable for materials with low vaporization temperatures, like plastic.

Common Applications

- Industrial Cutting: Used to cut sheets and plates of metals, plastics, wood, and composites.

- Medical Applications: CO2 lasers are used for precise tissue cutting and removal in surgeries.

- Engraving and Marking: Ideal for adding serial numbers to parts or creating artistic engravings on wood and other materials.

- 3D Printing: Used to fuse metal and plastic powders together to form 3D-printed parts.

- Laser Welding: Joins metals or thermoplastics with a laser beam instead of traditional welding methods.

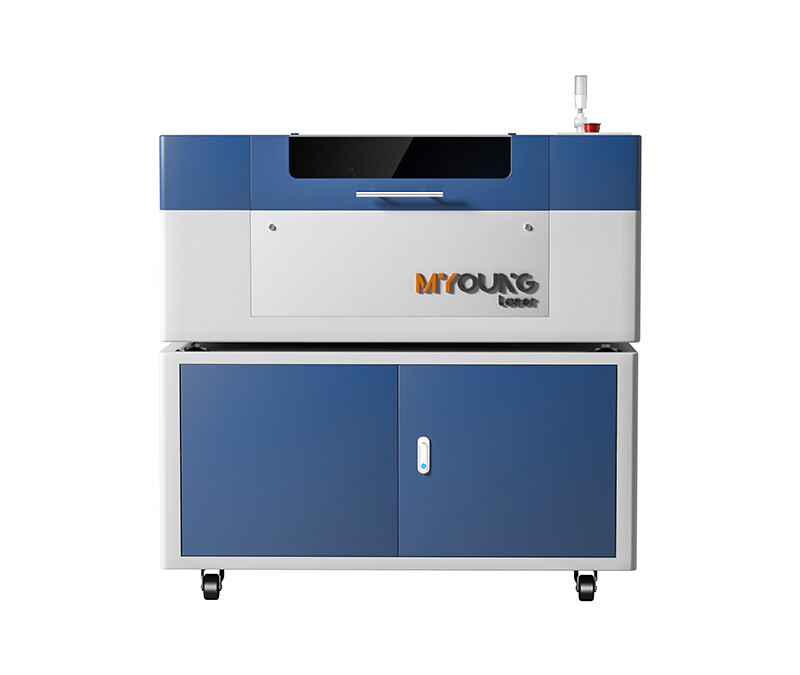

Introduction to Chinese CO2 Laser Machine Manufacturers

China is a leading producer of CO2 laser cutting machines, known for offering high-quality and cost-effective solutions. Chinese manufacturers have established a strong presence in the global market, catering to various industries.

Advantages of Chinese Manufacturers

Cost-Effectiveness:

Chinese manufacturers offer competitive pricing without compromising on quality, making their CO2 laser machines affordable for businesses of all sizes.

Technological Advancements:

Significant investments in research and development result in innovative and advanced laser cutting technologies.

Customization:

Tailored solutions to meet specific customer requirements, including custom machine sizes, power levels, and additional features.

Wide Range of Products:

A diverse selection of CO2 laser machines suitable for different applications, from small-scale projects to large industrial operations.

Strong After-Sales Support:

Robust after-sales service networks offering maintenance, training, and technical support.

Global Reach:

Reliable shipping and logistics services to customers worldwide.

Enhance your manufacturing capabilities with a CO2 laser cutting machine from leading Chinese manufacturers. Contact us today to find the perfect machine for your needs and take your production to the next level!