Why CO2 is Used in Laser Cutting Machines?

INDUSTRIAL NEWS

Why CO2 is Used in Laser Cutting Machines?

CO2 laser cutting machines have become a cornerstone in various industries due to their versatility, precision, and efficiency. This article provides a detailed explanation of why CO2 is used in laser cutting machines, delving into their history, the underlying principles, and modern technological advancements.

Historical Development of CO2 Lasers

Invention and Early Use

The CO2 laser was invented in 1964 by Kumar Patel at Bell Laboratories. It was one of the earliest gas lasers and quickly became popular due to its high efficiency and power output. Initially, CO2 lasers were used for scientific research and medical applications, but their potential for industrial use was soon recognized.

Industrial Adoption

By the late 1970s, CO2 lasers had begun to be adopted for industrial applications. Their ability to cut non-metallic materials like wood, acrylic, and plastic made them invaluable in manufacturing. Over time, advancements in technology allowed CO2 lasers to handle more complex tasks, including cutting metals with high precision.

How CO2 Lasers Work

Laser Generation

A CO2 laser operates by exciting a mixture of carbon dioxide, nitrogen, and helium gases with an electrical discharge. The CO2 molecules emit infrared light at a wavelength of approximately 10.6 micrometers. This light is then amplified and focused into a high-powered beam using mirrors and lenses.

Cutting Mechanism

The high-energy laser beam is directed at the material to be cut. The laser’s intense energy heats the material to its melting or vaporization point, allowing for precise and clean cuts. The process can be classified into three main types:

- Melt and Blow: The laser heats the material until it melts, and a high-pressure gas blows the molten material away.

- Reactive Cutting: The laser heats the material and a stream of oxygen enhances the cutting process through oxidation.

- Vaporization Cutting: The laser heats the material to its boiling point, causing it to vaporize directly.

Why CO2 is Ideal for Laser Cutting

High Efficiency and Power

CO2 lasers are highly efficient in converting electrical energy into laser light, often achieving efficiencies of 20-30%. This high efficiency translates into powerful cutting capabilities, making CO2 lasers suitable for both thin and thick materials.

Versatility

CO2 lasers can cut a wide range of materials, including metals, plastics, wood, and textiles. This versatility makes them an ideal choice for various industries, from manufacturing to artistic applications.

Precision and Quality

The focused CO2 laser beam provides high precision, allowing for intricate and detailed cuts. The quality of the cut is smooth and clean, reducing the need for additional finishing processes.

Modern Technological Advancements

Computer Numerical Control (CNC)

The integration of CNC technology with CO2 lasers has revolutionized the cutting process. CNC systems allow for automated and precise control of the laser beam, enabling complex designs and high repeatability.

Enhanced Safety and Environmental Features

Modern CO2 laser cutting machines come equipped with advanced safety features, including enclosed cutting areas and fume extraction systems. These features protect operators from harmful emissions and reduce environmental impact.

Improved Beam Quality and Stability

Advancements in optical components and cooling systems have improved the beam quality and stability of CO2 lasers. This ensures consistent performance and higher cutting speeds, further enhancing productivity.

Advantages of CO2 Laser Cutting Machines

- Versatility: Can cut a wide range of materials.

- Precision: High accuracy and detailed cuts.

- Efficiency: High energy conversion efficiency.

- Quality: Smooth and clean cut edges.

- Speed: High cutting speeds increase productivity.

Chinese CO2 Laser Machine Manufacturers

China has become a leading producer of CO2 laser cutting machines, offering high-quality and cost-effective options. Chinese manufacturers are known for:

- Innovation: Investment in research and development ensures cutting-edge technology.

- Affordability: Competitive pricing makes CO2 lasers accessible to various businesses.

- Quality: Adherence to international standards ensures reliability and performance.

CO2 laser cutting machines have transformed numerous industries with their precision, efficiency, and versatility. From their invention in the 1960s to modern technological advancements, these machines continue to evolve, providing improved performance and new capabilities. Chinese manufacturers play a significant role in the global market, offering high-quality and affordable solutions for CO2 laser cutting.

For more detailed information, you can refer to sources such as Wikipedia on CO2 Lasers.

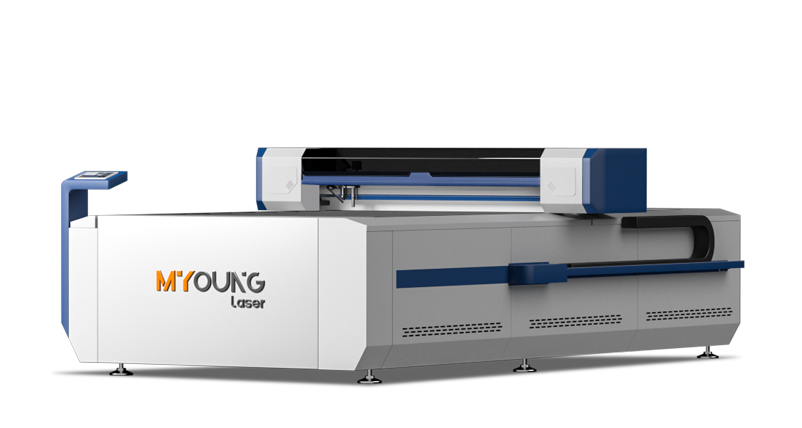

Interested in CO2 laser cutting machines? Discover our range of high-quality, efficient, and versatile CO2 lasers at Foshan Myoung Laser Technology Co., Ltd. Visit our website or contact us today to learn more about how our advanced CO2 laser machines can meet your cutting needs!