How to Create Stunning Designs Using Acrylic and CO2 Laser Machines

INDUSTRIAL NEWS

How to Create Stunning Designs Using Acrylic and CO2 Laser Machines

CO2 laser machines have revolutionized the world of design, enabling creators to produce intricate and precise cuts on materials like acrylic. Whether you’re working in industrial design, crafting, or fine arts, CO2 laser technology provides a level of detail and flexibility that was once hard to achieve with traditional methods. Below, we’ll explore how to make the most of these powerful machines, highlighting key steps in creating stunning designs, and why MYounglaser is a top choice among CO2 laser machine suppliers.

1. Understanding CO2 Laser Machines

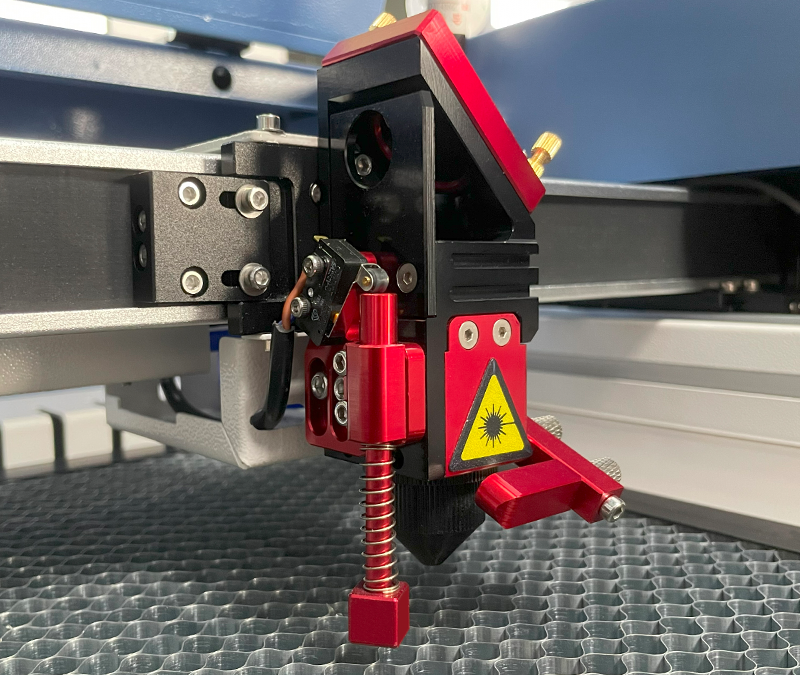

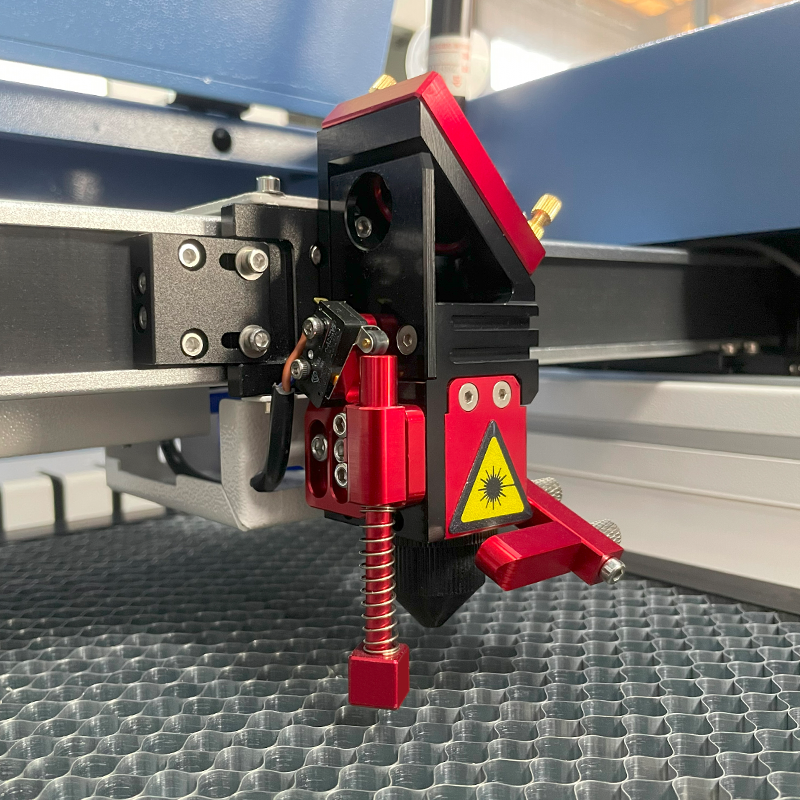

CO2 laser machines work by emitting a high-powered laser beam that cuts through or engraves materials, with acrylic being one of the most popular mediums for these machines. The laser is controlled by a computer, allowing for precise, intricate designs, whether for industrial parts or decorative items.

Benefits of Using CO2 Laser Machines for Acrylic:

- Precision: CO2 laser machines allow for fine details that would be nearly impossible with traditional cutting methods.

- Speed: You can quickly produce multiple identical pieces, making it ideal for production settings.

- Smooth Edges: Laser cutting leaves acrylic with clean, polished edges, eliminating the need for post-processing.

2. Preparing Your Design

Before you start cutting, you need a well-prepared design file. Most laser cutting software supports vector files (such as SVG or DXF), which provide the machine with the exact cutting paths.

Key Tips for Design Preparation:

- Use High-Quality Vector Files: Ensure your design is free from errors and ready to scale, especially if you’re producing large quantities.

- Layer Management: Organize different parts of the design into layers, so the machine knows where to cut, engrave, or leave unmarked.

- Preview the Cut: Always preview the design on the software before running the machine to avoid mistakes.

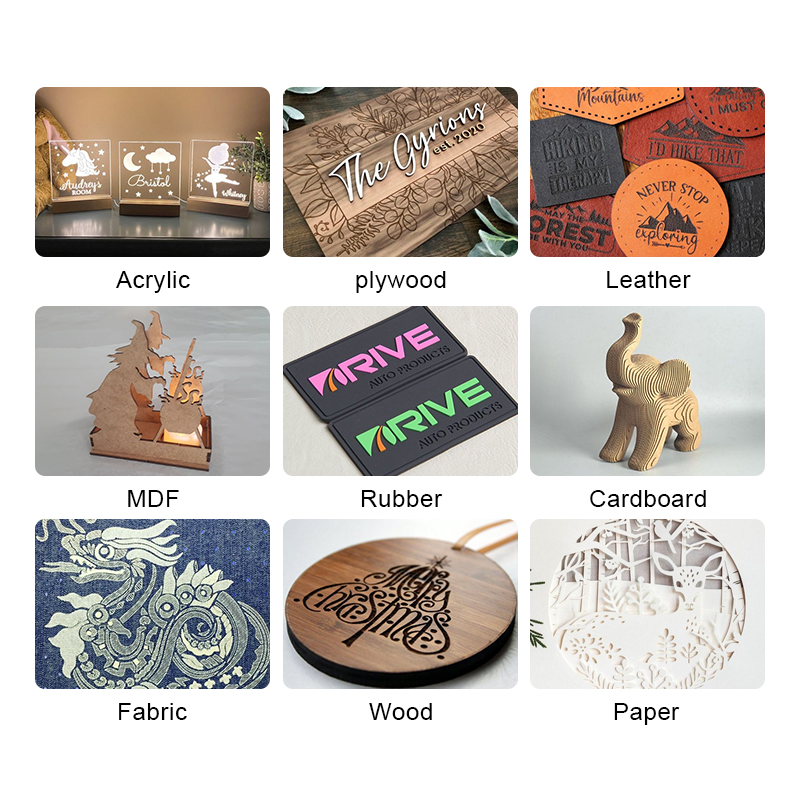

3. Material Selection: Why Acrylic?

Acrylic is one of the most laser-friendly materials. It’s easy to cut, engrave, and leaves a professional finish without additional treatment. It comes in various colors, thicknesses, and finishes, offering flexibility for both functional and artistic projects.

- Optical Clarity: Transparent acrylic has the glass-like quality that is perfect for displays, signage, and artistic pieces.

- Durability: It’s lightweight, shatter-resistant, and maintains its integrity even after intricate cuts.

- Versatility: Acrylic can be engraved for custom designs, logos, or even 3D effects.

4. Cutting Techniques for Acrylic Using CO2 Lasers

CO2 lasers excel in cutting acrylic due to their precision and efficiency. Here’s how to optimize the process:

a. Focus and Speed

For the best results, ensure that the laser is properly focused. Misalignment can lead to jagged or incomplete cuts. Additionally, adjusting the speed settings according to the acrylic’s thickness will result in smooth, polished edges.

b. Power Settings

Fine-tuning the laser power is key. Higher power is needed for thicker acrylic, but using too much can cause warping or burning. Testing on a scrap piece before the final cut is always a good idea.

c. Air Assist

Many CO2 laser machines, like those offered by MYounglaser, come with air assist, which blows away debris and cools the cutting area. This prevents burning and keeps the cut clean.

5. Engraving Acrylic with CO2 Laser Machines

Beyond cutting, CO2 laser machines are also excellent for engraving acrylic. By adjusting the laser’s power settings, you can etch intricate patterns, text, or images onto the surface.

- Etching Depth: Control the depth of the engraving by adjusting power and speed. Shallow engravings create subtle designs, while deeper ones provide more contrast.

- Frosted Finish: Engraving creates a frosted appearance on clear acrylic, giving a visually appealing texture.

- Layered Designs: You can engrave in multiple passes to create a 3D effect, adding depth to the design.

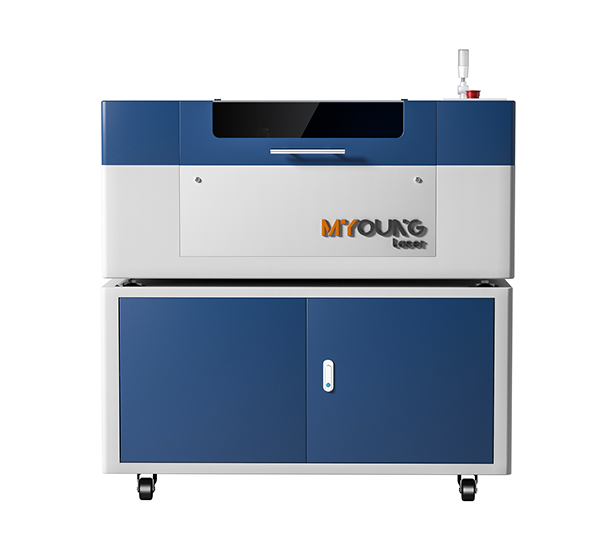

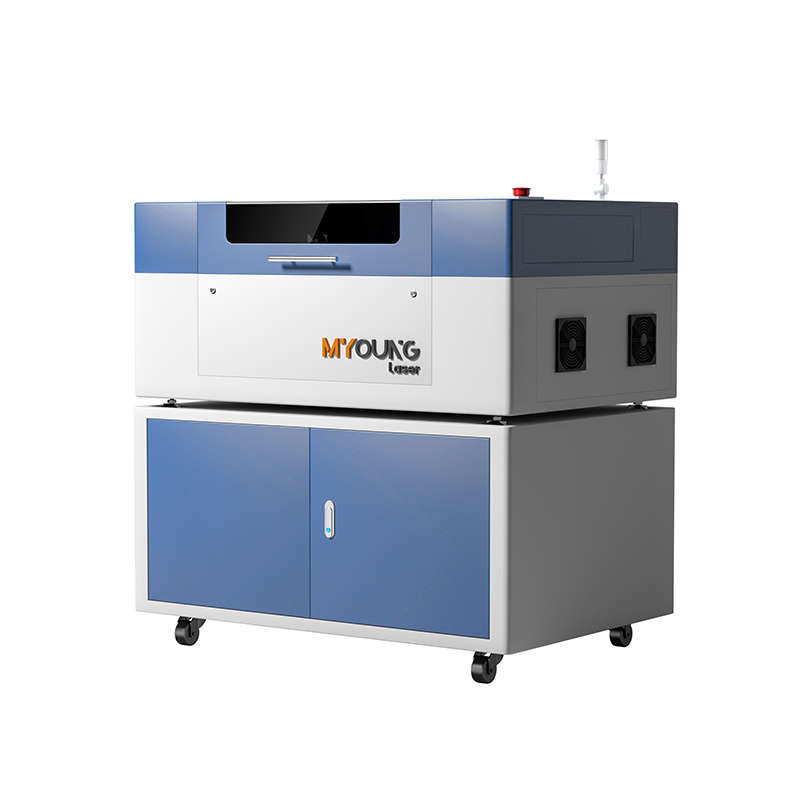

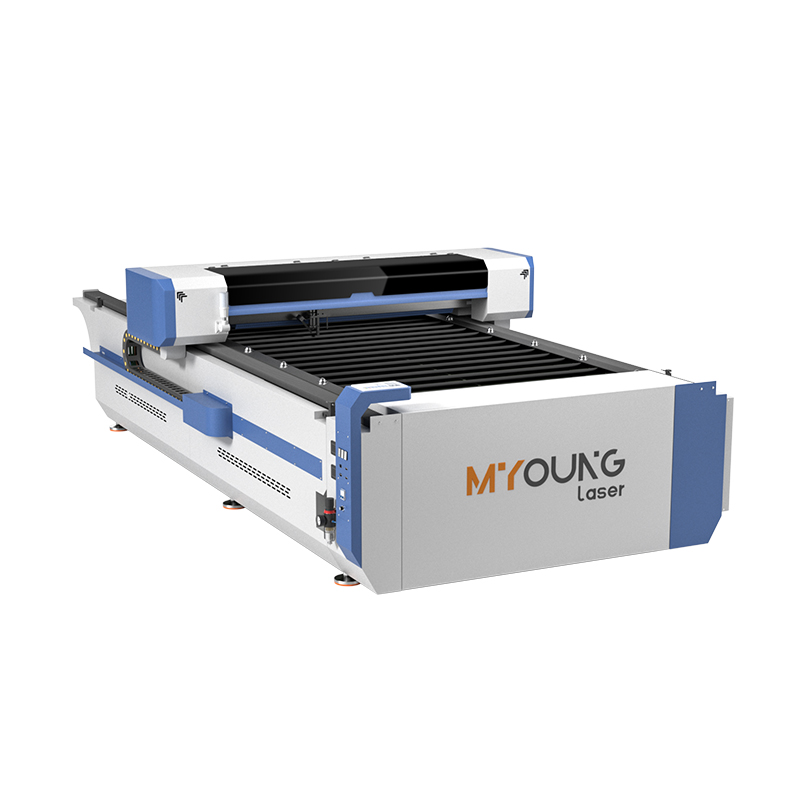

6. Choosing the Right CO2 Laser Machine

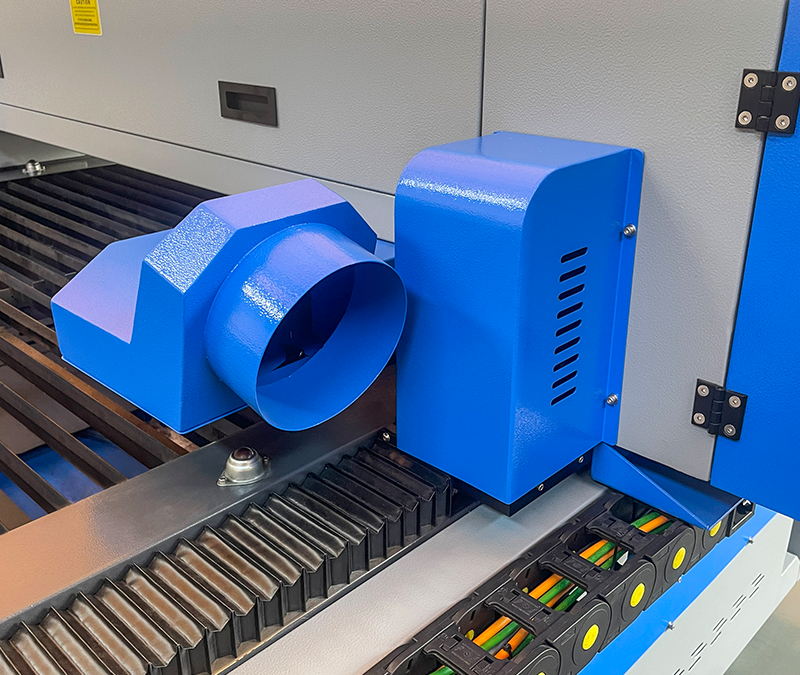

When investing in a CO2 laser machine, it’s essential to choose a model that fits your production needs. MYounglaser is known for producing reliable and efficient CO2 laser machines that cater to various industries, from small-scale crafters to large manufacturers.

Key Features to Consider:

- Bed Size: Ensure the machine’s working area is large enough to accommodate your typical projects.

- Power: Machines like those from MYounglaser come in different wattages, from 150W to 300W, providing flexibility depending on the thickness of acrylic you’re working with.

- Software Compatibility: Look for machines with user-friendly software that integrates easily with popular design tools like Adobe Illustrator or AutoCAD.

7. Why Choose MYounglaser?

As a top CO2 laser machine supplier, MYounglaser stands out for its innovative technology and robust equipment. Whether you need a machine for precise acrylic cutting or large-scale industrial operations, MYounglaser offers:

- High-performance laser machines that are both efficient and durable.

- Excellent customer service and support for setting up and optimizing the machine.

- Competitive pricing, making it an excellent investment for businesses of all sizes.

Creating stunning acrylic designs with CO2 laser machines is not only achievable but also efficient and cost-effective. With the right machine, like those offered by MYounglaser, you can take your design work to the next level, whether it’s for personal projects or industrial production.

If you’re looking for reliable CO2 laser machine suppliers, consider MYounglaser. Their machines are designed to handle a wide range of materials, ensuring that your acrylic projects always stand out with precision and elegance.

Explore the possibilities today with MYounglaser and start crafting your stunning acrylic designs!