Top 5 Benefits of Using Acrylic with CO2 Laser Machines

INDUSTRIAL NEWS

Top 5 Benefits of Using Acrylic with CO2 Laser Machines

Acrylic has gained immense popularity for laser cutting due to its versatility, durability, and the precision offered by CO2 laser machines. Whether it’s for signage, decorative products, or industrial applications, the synergy between acrylic and CO2 laser machines, such as those offered by MYounglaser, is unmatched. In this guide, we’ll look at the top five reasons why acrylic is the material of choice for CO2 laser machines and how MYounglaser’s Dura series enhances these benefits.

Precision Cutting and Engravin

Acrylic can be cut with incredible accuracy using CO2 laser machines, making it perfect for projects that require detailed work such as signage, custom artwork, or display pieces. MYounglaser’s Dura series CO2 laser machines take this precision further with their high-speed rail system, ensuring each cut is smooth and clean, even for intricate designs.

Clean and Polished Edges

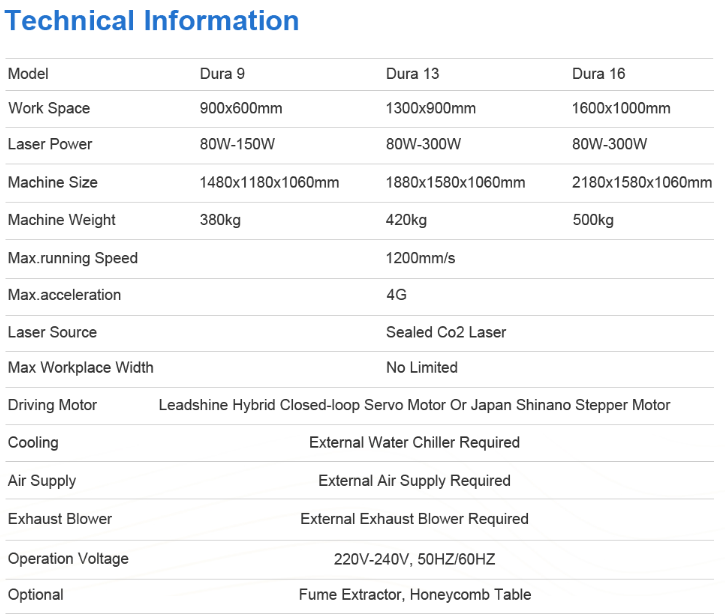

When laser-cut, acrylic produces polished edges that don’t require additional finishing. The Dura 9, Dura 13, and Dura 16 models from MYounglaser ensure a flame-polished finish, saving both time and effort in post-processing while maintaining high quality. This makes the Dura series perfect for applications like trophies, signage, and decorative items.

Versatility in Thickness and Colors

Acrylic is available in various thicknesses and colors, allowing for endless creative applications. Whether you’re working with thin sheets for delicate designs or thicker materials for structural pieces, the Dura series machines are equipped to handle them all with ease, thanks to their power options ranging from 80W to 300W. This ensures maximum flexibility and precision no matter the project size.

Cost-Effective Material for Mass Production

Acrylic is an affordable material, especially when compared to wood or metal, and with the speed and efficiency of MYounglaser’s Dura series machines, large production runs are more cost-effective. These machines can handle production speeds up to 1200mm/s, reducing turnaround times, making them ideal for producing large quantities of acrylic products like custom signs, packaging, and panels.

Durability and Weather Resistance

Acrylic is highly durable and resistant to weather, making it the perfect material for both indoor and outdoor applications. The Dura series CO2 laser machines allow for the creation of long-lasting outdoor signage and decorative panels that withstand the elements while maintaining their visual appeal over time.

For precision, versatility, and durability, acrylic combined with MYounglaser’s Dura series CO2 laser machines offers an unbeatable solution. The Dura 9, Dura 13, and Dura 16 are engineered for speed, efficiency, and quality, ensuring your acrylic projects meet the highest standards, whether you’re creating small-scale items or mass-producing goods.

Why Choose MYounglaser’s Dura Series?

The Dura series is designed to maximize efficiency with advanced features such as:

- Linear module guide rails for smoother, quieter operation.

- Japan Shinano motors ensuring high torque and precision.

- Self-cleaning capabilities that reduce maintenance.

- Optional customizations for fume extraction and table types, making it perfect for any acrylic cutting need.

If you’re ready to take your acrylic cutting projects to the next level, MYounglaser’s Dura series is the perfect choice. Contact us today for more information on how we can help you find the right machine for your needs!