The Environmental Impact of Acrylic Laser Cutting

INDUSTRIAL NEWS

The Environmental Impact of Acrylic Laser Cutting

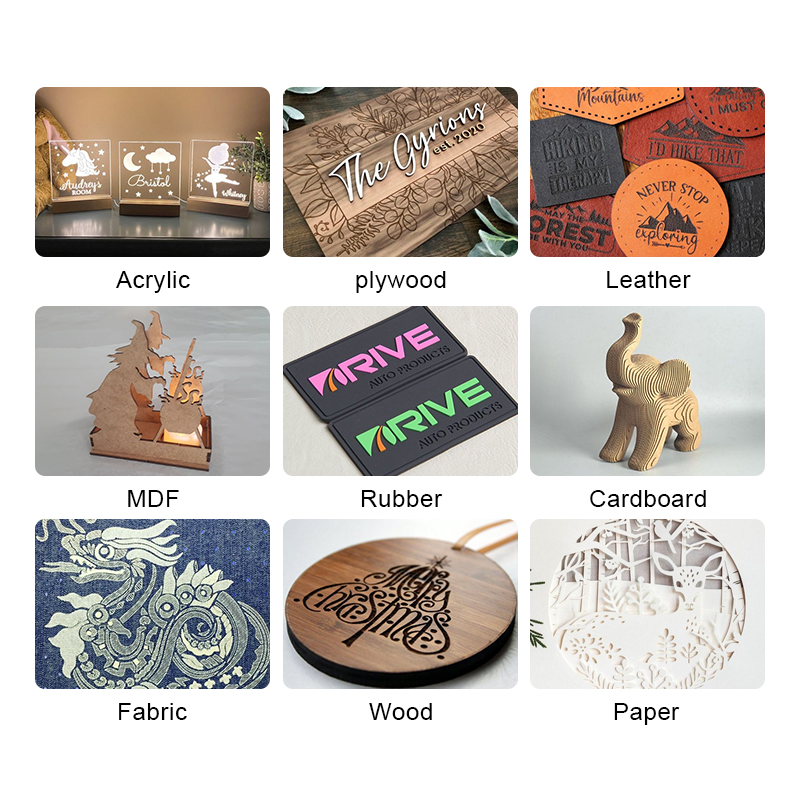

Laser cutting technology, particularly with CO2 laser machines, has revolutionized the way acrylic is processed, offering precise, efficient, and versatile solutions for various industries. However, with the growing focus on sustainability, it is essential to assess the environmental impact of this process and explore ways to minimize negative outcomes.

In this article, we delve into the environmental aspects of acrylic laser cutting, including material considerations, emissions, energy consumption, and strategies for making the process more sustainable.

1. Acrylic as a Material: Environmental Perspective

Acrylic, also known as polymethyl methacrylate (PMMA), is a widely used material for its transparency, durability, and versatility. However, its environmental impact raises some concerns:

- Production: Acrylic is derived from petrochemicals, and its production is energy-intensive, contributing to greenhouse gas emissions.

- Recyclability: Unlike some plastics, acrylic can be recycled, but the recycling process is not widely implemented and may require specialized facilities.

Despite these challenges, its durability means that products made from acrylic can have a long lifespan, reducing the need for frequent replacements.

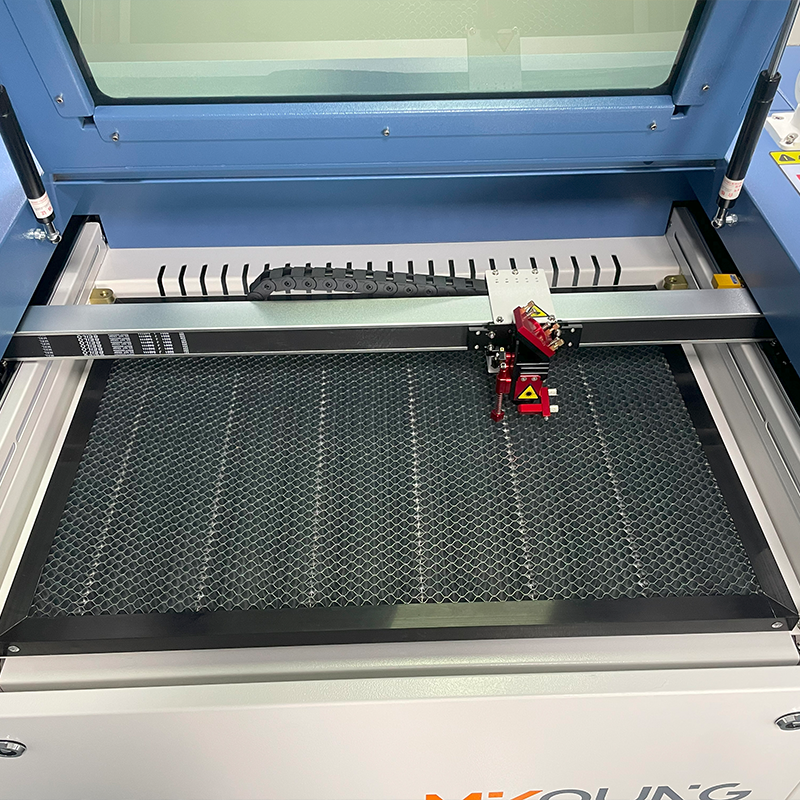

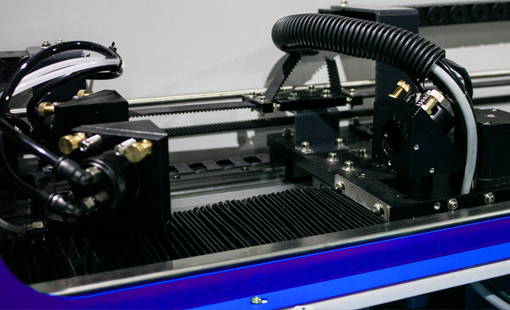

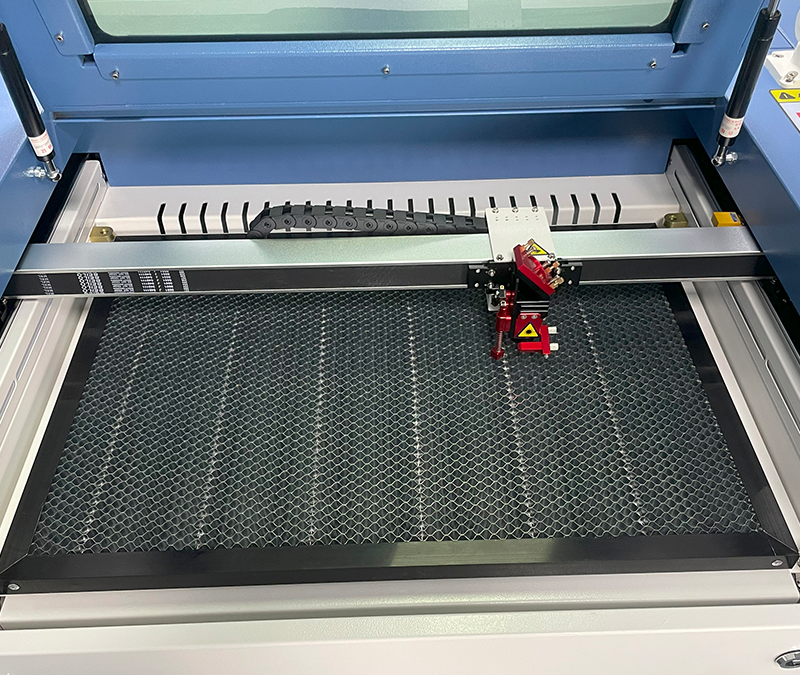

2. Energy Consumption of CO2 Laser Machines

CO2 laser machines, such as those from MYounglaser, are efficient in terms of material use but do require significant energy to operate. Factors influencing energy consumption include:

- Laser Power: Higher power machines consume more energy, especially when cutting thicker acrylic materials.

- Operational Efficiency: Advanced CO2 laser machines, like those offered by MYounglaser, optimize energy use through precise controls and efficient cooling systems.

By selecting the appropriate machine for your needs and using it efficiently, businesses can minimize energy wastage.

3. Emissions from Acrylic Laser Cutting

When acrylic is cut with a CO2 laser, it releases fumes and particulates. These emissions include:

- Volatile Organic Compounds (VOCs): Generated from the thermal decomposition of acrylic, VOCs can contribute to air pollution if not properly managed.

- Odors and Particulates: These byproducts can affect indoor air quality if adequate ventilation or air filtration systems are not in place.

MYounglaser CO2 machines are designed with integrated air filtration systems that capture and neutralize harmful emissions, promoting a safer and more eco-friendly cutting process.

4. Waste Generation

Laser cutting produces minimal material waste compared to traditional cutting methods, as it is highly precise. However:

- Acrylic Scraps: These can often be reused for smaller projects or recycled if facilities are available.

- Dust and Residue: Proper cleaning and maintenance of the laser machine can help manage and reduce these byproducts.

5. Sustainable Practices for Acrylic Laser Cutting

To reduce the environmental footprint of acrylic laser cutting, businesses can adopt the following strategies:

- Material Optimization: Plan cutting layouts to maximize material use and reduce waste.

- Invest in Eco-Friendly Equipment: Choose machines with energy-efficient features and effective emission control, such as MYounglaser’s advanced CO2 laser systems.

- Recycle and Reuse: Partner with recycling facilities that can handle acrylic waste and explore creative ways to repurpose scraps.

- Maintain Equipment: Regularly service CO2 laser machines to ensure optimal performance and energy efficiency.

- Use Sustainable Acrylic: Seek out suppliers that offer eco-friendly or recycled acrylic options.

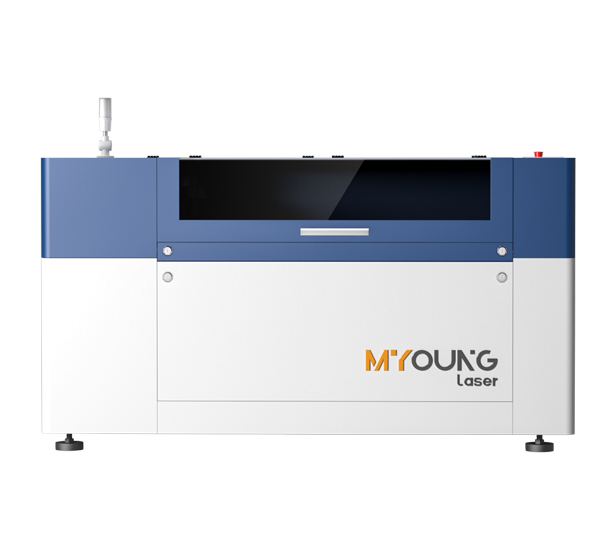

6. MYounglaser: A Sustainable Choice

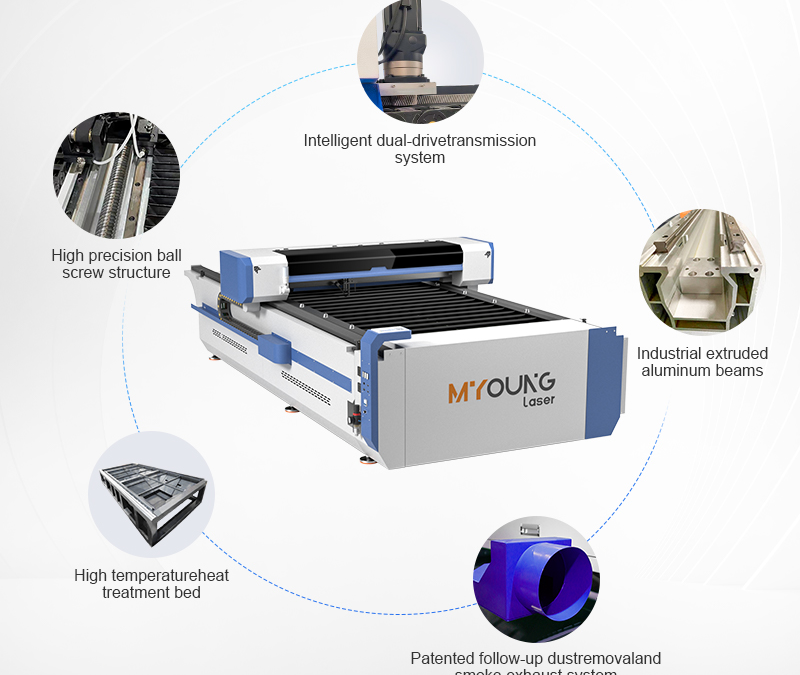

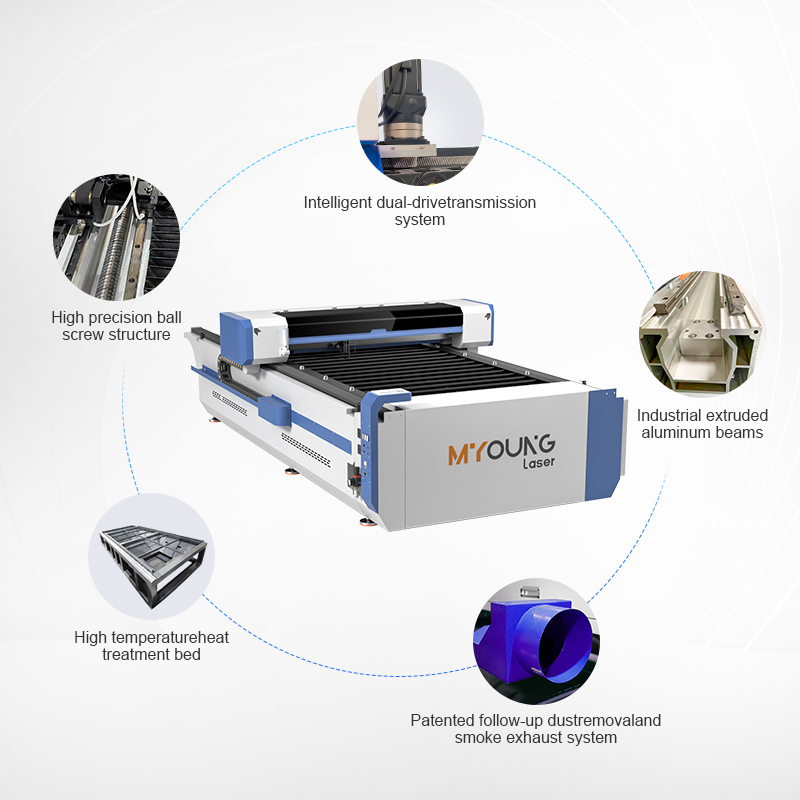

MYounglaser is committed to providing environmentally conscious solutions with its range of CO2 laser machines. Key features include:

- Energy Efficiency: Machines designed to minimize energy consumption without compromising on performance.

- Advanced Air Filtration: Built-in systems to reduce harmful emissions during acrylic cutting.

- Durable and Reliable: Long-lasting machines that reduce the need for frequent replacements, lowering the overall environmental impact.

By choosing MYounglaser CO2 laser machines, businesses can meet their production goals while contributing to sustainability efforts.

Acrylic laser cutting, while not entirely without environmental impact, can be made significantly more sustainable through careful material selection, efficient machine use, and waste management. By investing in high-quality machines like those from MYounglaser and adopting eco-friendly practices, businesses can minimize their footprint while achieving outstanding cutting precision.

Looking for an energy-efficient, eco-friendly CO2 laser machine? Explore MYounglaser’s range today and take a step toward sustainable laser cutting.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.