Common Issues in Acrylic CO2 Laser Cutting and Effective Solutions

INDUSTRIAL NEWS

Common Issues in Acrylic CO2 Laser Cutting and Solutions

Acrylic CO2 laser cutting has become a go-to method for achieving clean, precise cuts and engravings. However, like any technology, it comes with its own set of challenges that may affect cutting quality and efficiency. Here, we’ll outline some common issues encountered in acrylic laser cutting and provide effective solutions to help maintain the performance of your CO2 laser machine.

1. Poor Edge Quality

- Issue: When cutting acrylic, edges may come out rough, cloudy, or scorched, which detracts from the final product’s quality.

- Solution:

- Optimize Settings: Adjust your laser’s power and speed settings. High power and low speed may produce clean, polished edges but can scorch the acrylic if not calibrated. Start with lower power and gradually increase it.

- Air Assist: Use an air assist function to blow away debris and maintain a consistent cut. This keeps edges cleaner and minimizes scorching.

2. Material Warping

- Issue: Acrylic can warp if exposed to high temperatures for too long during cutting or engraving, leading to uneven surfaces.

- Solution:

- Proper Speed and Power Balance: Reduce laser power or increase speed to prevent overheating. Setting your machine for quick passes can help, especially for thicker acrylics.

- Work in Layers: For deep engravings, consider engraving in multiple shallow passes instead of one deep pass to avoid excess heat buildup.

3. Melting and Distortion of Acrylic

- Issue: CO2 lasers can sometimes generate excessive heat, causing acrylic to melt and distort.

- Solution:

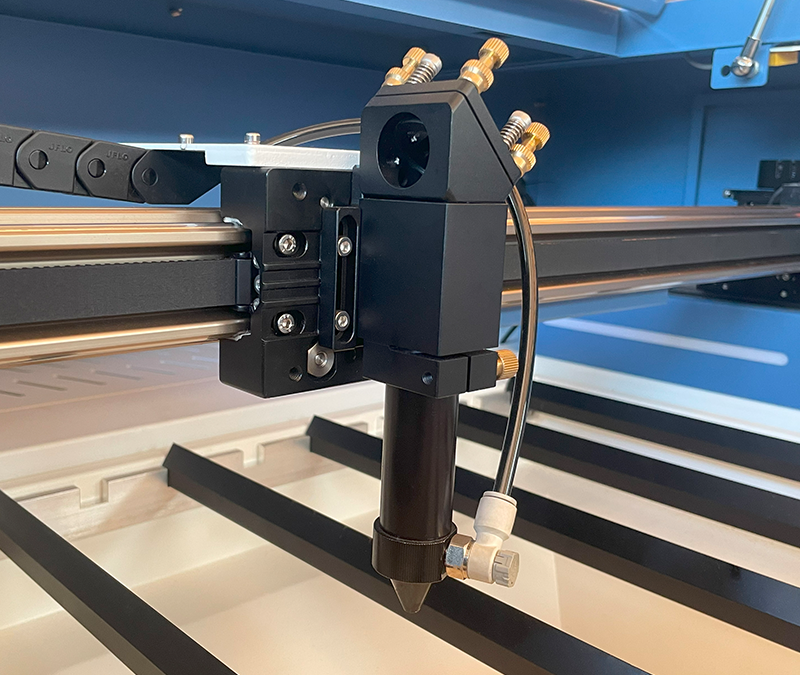

- Optimize Focus and Frequency: Ensure the focus is adjusted accurately to keep the laser beam concentrated. Lower frequencies can minimize heat buildup, reducing the risk of melting.

- Use Cast Acrylic: Cast acrylic is generally more resilient to heat compared to extruded acrylic, which is more prone to melting and distortion.

4. Inconsistent Engraving Depth

- Issue: Inconsistent depth can make designs appear uneven or faded.

- Solution:

- Regular Maintenance: Dust or debris on lenses and mirrors can affect the laser’s power, leading to inconsistent cuts. Clean optical components regularly.

- Material Stability: Ensure the acrylic sheet is flat and stable on the work table. Any gaps or warping in the material can lead to uneven engraving.

5. Laser Beam Misalignment

- Issue: Misalignment of the laser beam can cause cuts to be off-center or lead to uneven edges.

- Solution:

- Realign Mirrors: CO2 laser machines often require regular alignment of their mirrors. Follow your machine’s alignment procedure to ensure the beam is hitting the focal lens accurately.

- Routine Checks: Regularly inspect mirror and lens alignment, especially if your machine is moved frequently, as vibrations can shift components out of place.

6. Residual Burn Marks on Surface

- Issue: Burn marks around the cut edges can be an aesthetic issue, especially in transparent acrylic.

- Solution:

- Masking Tape: Apply masking tape to the surface of the acrylic before cutting to prevent the laser from scorching the top layer.

- Reduce Power: Lower power settings slightly and increase speed. This minimizes burn marks by reducing the time the laser spends in any single location.

Using MYounglaser CO2 Laser Machines for Superior Results

For consistent, high-quality acrylic cuts, MYounglaser CO2 Laser Machines are engineered with advanced features to mitigate many of these common issues. Equipped with Japan Shinano motors for high precision, these machines offer exceptional control over laser speed and power, allowing users to fine-tune settings for each specific project. Additionally, MYounglaser machines include built-in cooling and dust-removal systems, helping prevent overheating and keeping optics clean to ensure precision with every cut.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

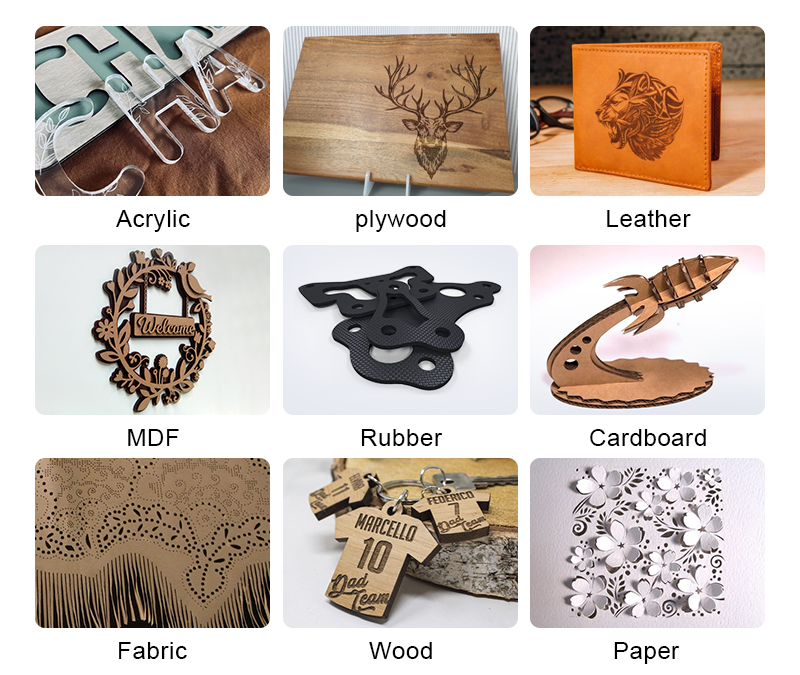

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.