How to Combine Acrylic Laser Cutting with UV Printing

INDUSTRIAL NEWS

How to Combine Acrylic Laser Cutting with UV Printing

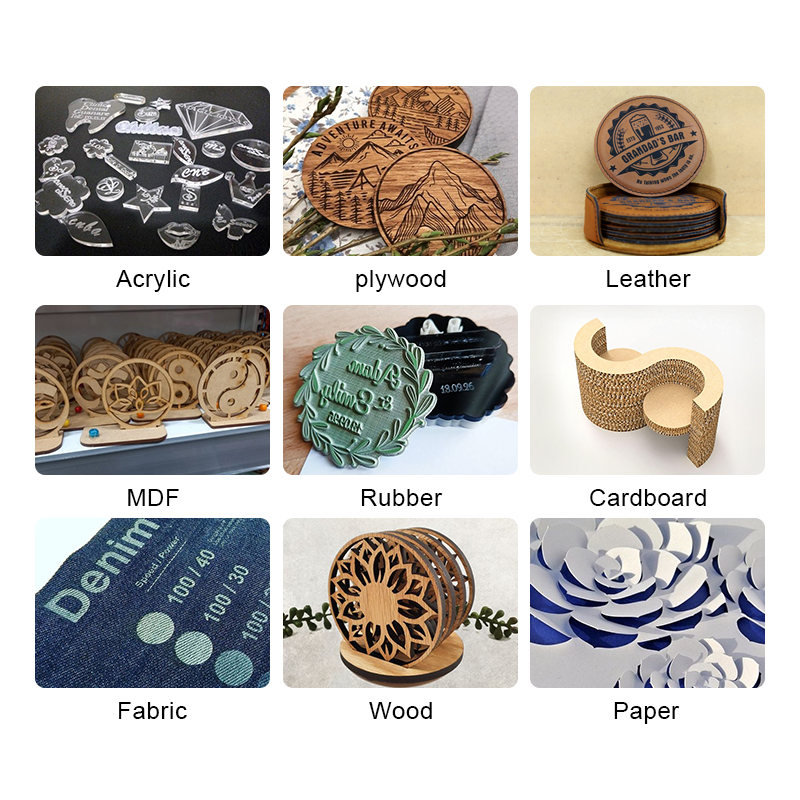

Acrylic laser cutting and UV printing are two advanced technologies that complement each other beautifully. When combined, they open up a world of creative possibilities, producing high-quality, custom-designed products. Here’s how you can merge these two technologies effectively, with a focus on their applications, processes, and benefits.

The Power of Combining Acrylic Laser Cutting with UV Printing

Acrylic Laser Cutting: Precision Meets Creativity

Using a CO2 laser machine, such as those offered by MYounglaser, you can cut and engrave acrylic with unparalleled precision. CO2 lasers are perfect for creating intricate designs, sharp edges, and detailed engravings on acrylic sheets.

UV Printing: Vibrant and Durable Designs

UV printing involves using ultraviolet light to cure ink directly onto the surface of materials like acrylic. This process produces vibrant colors, excellent durability, and a variety of textures.

By combining these two techniques, businesses can create:

- Customized signage.

- Decorative panels.

- Personalized gifts and promotional items.

- High-end retail displays.

Step-by-Step Guide to Combining These Technologies

Step 1: Prepare Your Acrylic Material

Choose the right type and thickness of acrylic for your project. Thinner sheets are suitable for small, delicate designs, while thicker sheets work well for larger projects. Ensure the acrylic is clean and free of debris before cutting.

Step 2: Design for Laser Cutting

Use vector-based design software like CorelDRAW or Adobe Illustrator to create your laser cutting design. A CO2 laser machine, such as MYounglaser’s Dura series, ensures precise cuts and smooth edges.

Key Tips:

- Optimize settings based on acrylic thickness.

- Test your design on scrap material to fine-tune laser power and speed.

Step 3: Perform the Laser Cutting

Load the design file onto your laser machine and cut the acrylic. Ensure proper ventilation and follow safety guidelines during the process.

Step 4: Clean and Polish

After cutting, clean the acrylic surface to remove any residue. Use a polishing tool for smooth, professional edges if necessary.

Step 5: Prepare for UV Printing

Once the acrylic is cut, design the UV printing artwork. Ensure the design aligns perfectly with the cut shape. Many UV printers include software for precise positioning.

Step 6: UV Printing on Acrylic

Load the acrylic into the UV printer and start the printing process. Adjust settings for ink density and curing based on the acrylic’s surface and intended use.

Applications of Combined Laser Cutting and UV Printing

Retail and Advertising

- Eye-catching acrylic displays with vibrant graphics.

- Customized branding elements like logos and signs.

Interior Design

- Decorative wall panels and light fixtures.

- Personalized home decor items.

Corporate Gifts and Event Memorabilia

- High-quality awards, plaques, and promotional gifts.

Product Prototyping

- Precise prototypes with visually appealing designs.

Benefits of Combining Acrylic Laser Cutting and UV Printing

- Enhanced Customization: Tailor designs to meet specific client needs.

- Professional Finish: Create products with clean cuts and stunning graphics.

- Cost-Effective Production: Ideal for small-batch and mass production.

- Increased Durability: UV-printed designs resist fading, ensuring long-lasting results.

Why Choose MYounglaser Machines?

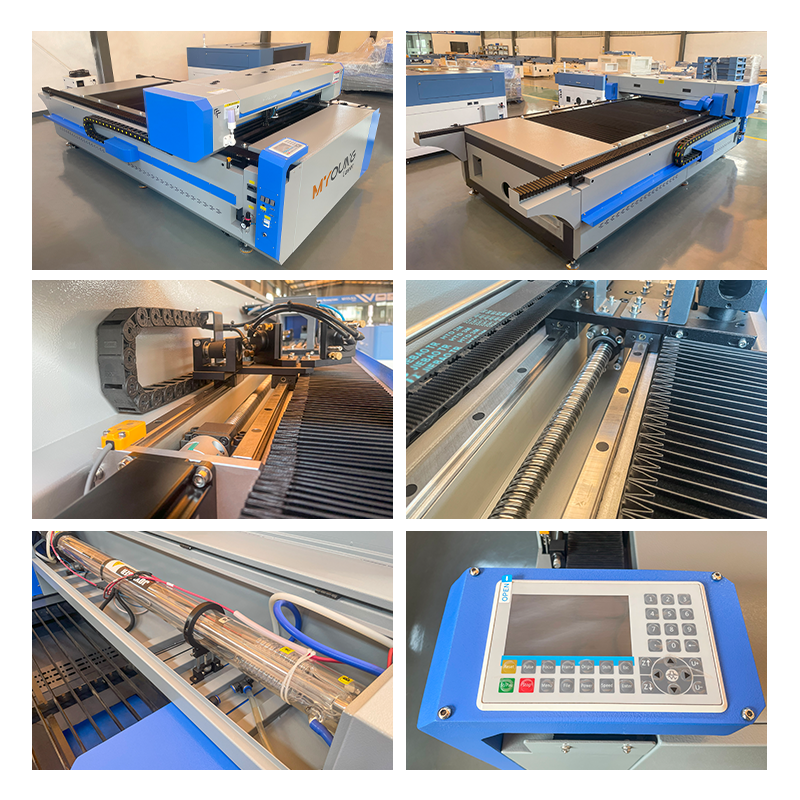

MYounglaser’s CO2 laser machines are engineered for high precision and efficiency, making them the perfect partner for combining laser cutting with UV printing. With:

- Advanced features like linear guide rails and high-speed motors.

- Compatibility with a wide range of acrylic thicknesses.

- Reliable performance backed by quality components.

Conclusion: Creativity Meets Technology

Combining acrylic laser cutting with UV printing is a game-changer for businesses looking to create standout products. Whether for signage, decor, or personalized gifts, the precision of MYounglaser CO2 laser machines and the vibrant quality of UV printing ensure unmatched results.

Explore our Dura series CO2 laser machines and take your creative projects to the next level. Contact us today to learn more!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.