INDUSTRIAL NEWS

How to Reduce Waste in Acrylic Laser Cutting Projects

Using an acrylic CO2 laser cutting machine is highly efficient for creating intricate designs and products, but maximizing the machine’s capabilities and maintaining cutting precision often require additional tools and accessories. Here’s a guide to some essential accessories that enhance efficiency, precision, and ease of operation when working with acrylic CO2 laser cutting machines, such as those provided by MYounglaser.

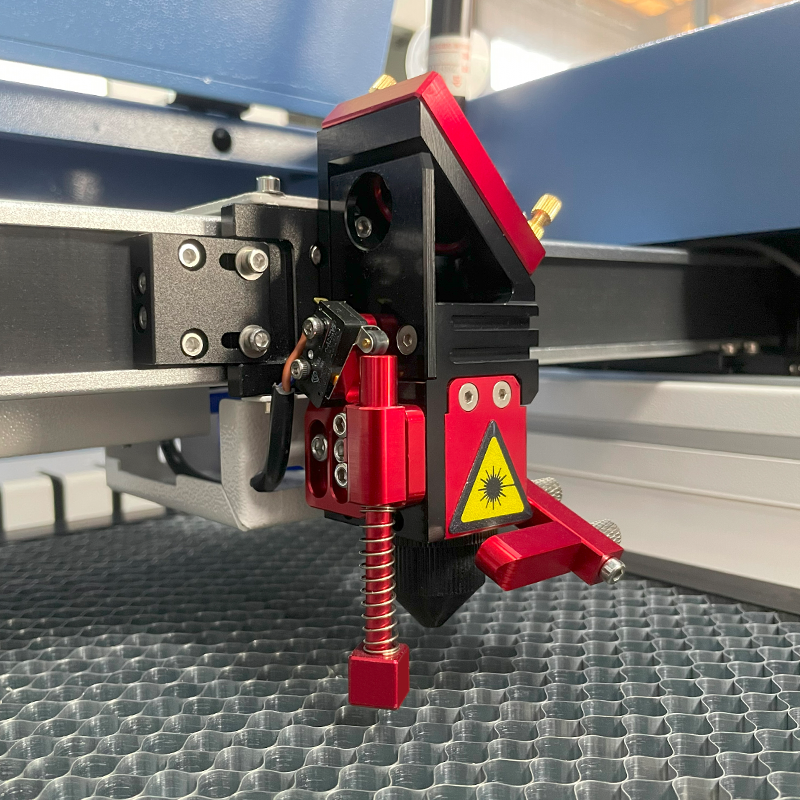

1. Air Assist Systems

An air assist system is crucial for acrylic laser cutting as it directs a stream of air onto the cutting surface. This helps keep the cut edges clear of debris and minimizes the risk of melting or burning.

- Benefits: Reduces material warping and improves edge quality.

- Maintenance: Regularly clean and check the airflow to prevent blockages and ensure optimal performance.

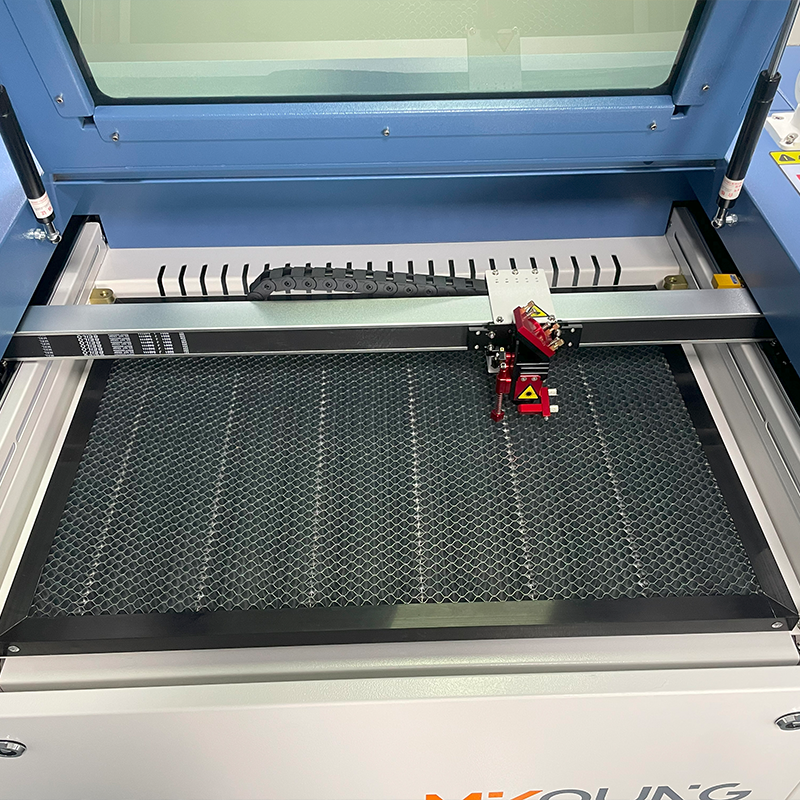

2. Honeycomb Worktable

A honeycomb worktable is a specialized cutting bed designed to support the material during cutting while allowing exhaust to flow through, reducing smoke and improving cut clarity.

- Material Holding: This table minimizes material movement and prevents any unwanted marking on the acrylic.

- Cooling Benefit: The airflow helps keep the cutting temperature lower, which is especially useful for acrylic projects to avoid warping.

3. Laser Fume Extractors

Laser cutting acrylic can release fumes and particles that are both harmful to users and the environment. A fume extractor is essential to filter out harmful emissions.

- Filtration: Filters out particulates and fumes to improve air quality.

- Machine Longevity: Protects internal machine components from exposure to fumes, reducing maintenance needs.

4. Rotary Attachments

A rotary attachment is essential for cutting or engraving cylindrical acrylic items, like bottles or round tubes. This accessory rotates the material as it’s cut, allowing for 360° engraving and intricate patterns.

- Compatibility: Ensure the rotary attachment is compatible with your machine’s settings and design software.

- Versatility: Opens possibilities for creating customized cylindrical products, ideal for décor or branded items.

5. External Water Chiller

The laser tube in a CO2 machine can heat up quickly, especially during prolonged use. A water chiller helps keep the tube cool, preventing overheating and ensuring consistent performance.

- Temperature Stability: Regulates the tube temperature to protect against heat damage.

- Improved Lifespan: Helps extend the life of the laser tube and keeps the machine operating at its best.

6. Lens and Mirror Cleaning Kit

Precision in laser cutting relies heavily on clean optics. A lens and mirror cleaning kit is essential to maintain clear, accurate laser paths.

- Improved Laser Quality: Regular cleaning prevents dust buildup, maintaining the laser’s strength.

- Kit Components: Typically includes cleaning solution, lint-free cloths, and specialized tools for handling delicate optics.

7. Positioning Laser

A positioning laser, sometimes called a red dot pointer, projects a visible laser beam onto the cutting surface, allowing you to see exactly where the cut will begin.

- Precision Placement: Simplifies setup and reduces alignment errors.

- Time Efficiency: Reduces trial-and-error adjustments, saving time on each project.

8. Air Compressor

An air compressor provides consistent airflow for air-assist systems. This accessory helps keep cuts clean and reduces the risk of melted edges.

- Cut Quality: Maintains edge sharpness and clarity, especially important for acrylic.

- Noise Control: Choose models with noise reduction for a quieter working environment.

9. Software for Design and Layout Optimization

High-quality software designed for laser cutting can help optimize layouts, reduce waste, and create complex designs.

- Layout Efficiency: Improves material usage and reduces waste.

- Design Precision: Compatible with most laser cutters, software like LightBurn allows intricate design control and editing features tailored to laser cutting needs.

10. Protective Eyewear

Even with a closed laser system, there’s always a possibility of reflected light. Investing in laser-rated protective eyewear is essential for safety.

- Protection Standards: Use eyewear rated for the specific wavelength of your laser to ensure complete eye safety.

- Durability: High-quality eyewear can be reused long-term, making it a valuable investment for regular laser cutting tasks.

Choosing the right accessories for your MYounglaser CO2 laser cutting machine not only enhances the efficiency and quality of your work but also helps ensure safety and longevity. Each accessory—whether it’s an air assist, rotary attachment, or a fume extractor—plays a role in perfecting the acrylic cutting process, allowing you to create high-quality products efficiently.

For those looking to equip their setup with durable, reliable laser cutting machines, MYounglaser’s CO2 models offer robust compatibility with these essential accessories, maximizing productivity and quality.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.