INDUSTRIAL NEWS

Cutting Acrylic for Interior Design Projects with CO2 Lasers

Using a CO2 laser machine to cut acrylic for interior design projects opens up endless possibilities. From custom lighting fixtures and intricate wall art to sleek furniture pieces, the precision and versatility of CO2 laser cutting have made it a go-to tool for interior designers aiming to bring unique, polished designs to life. In this guide, we’ll explore the benefits, techniques, and tips for using acrylic and CO2 laser technology in interior design projects.

1. Why Use Acrylic in Interior Design?

Acrylic is a top choice in modern design due to its versatility, durability, and crystal-clear finish, mimicking glass while offering added durability and lower weight. For laser cutting, acrylic’s heat-resistant properties allow for smooth, detailed edges with minimal post-processing. Additionally, acrylic is available in multiple colors, textures, and thicknesses, making it ideal for personalized design projects.

Popular Applications in Interior Design:

- Light Fixtures: Acrylic’s transparency and polished edges make it ideal for lamps and pendant lights that disperse light beautifully.

- Wall Art: Create 3D wall accents, abstract art, and even intricate patterns.

- Furniture and Décor Elements: Acrylic panels and blocks are common in creating lightweight, modern furniture and decorative accents.

2. Advantages of Using CO2 Laser Machines for Acrylic

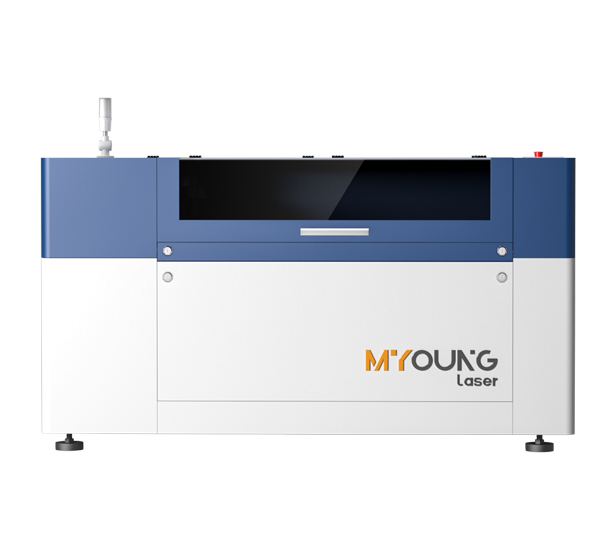

MYounglaser’s CO2 laser machines provide the precision and flexibility needed for crafting acrylic pieces in various sizes and shapes. Benefits of using CO2 laser cutting for interior design projects include:

- Precision: High precision in cutting and engraving allows for complex designs, even on small or delicate pieces.

- Edge Quality: CO2 lasers create smooth, polished edges on acrylic, eliminating the need for secondary polishing.

- Customizability: The technology makes it easy to create one-of-a-kind pieces, from geometric shapes to personalized text and designs.

3. Selecting the Right Acrylic Thickness

For interior design applications, acrylic thickness can affect both aesthetic and practical qualities:

- 1-3mm: Suitable for smaller details, decorative patterns, and wall art.

- 5-10mm: Works well for sturdy items like tabletops, light fixtures, and room dividers.

- 15mm and Above: Ideal for structural elements, such as shelving or large-scale installations.

4. CO2 Laser Cutting Tips for Acrylic in Interior Design Projects

To achieve top-quality results when using CO2 lasers with acrylic, follow these key steps:

A. Fine-Tune Laser Settings

The right combination of power, speed, and frequency settings is crucial:

- Power: For thinner sheets (1-3mm), start with low to medium power (around 30-40%); for thicker sheets, increase to 70-80%.

- Speed: Moderate speed settings reduce burn marks. For intricate patterns, use slower speeds to maintain detail.

- Frequency: Set your machine’s frequency to 500-1000 Hz to ensure smooth, continuous cuts.

B. Use Protective Film

Acrylic often comes with a protective film on one or both sides. Keep it on during the cutting process to protect against scratches and dust. Remove it after the cutting is complete for a pristine surface.

C. Optimize for Heat Management

Using an air assist feature helps keep acrylic cool, reducing the risk of burn marks on intricate designs. MYounglaser’s CO2 laser machines often include effective cooling options, maintaining high precision in cutting while minimizing heat buildup.

D. Test on Scrap Acrylic

To avoid wasting material, do a few trial cuts on scrap pieces, especially when cutting unfamiliar thicknesses or designs. This also lets you confirm that your machine settings are optimal.

5. Innovative Interior Design Ideas Using Acrylic and CO2 Lasers

Here are some ways you can use CO2 lasers to transform acrylic into stunning interior design elements:

- Customized Room Dividers: Acrylic panels cut into intricate patterns make stylish dividers that let light through while offering some privacy.

- Backlit Wall Features: Combine clear and frosted acrylic with LED lights to create dynamic backlit walls for a modern touch.

- Acrylic Shelving and Display Units: Clear or colored acrylic shelves add a modern, open feel to spaces and can be cut into unique shapes.

- Personalized Decorative Elements: Wall art, quotes, and other decorative elements can be cut precisely and customized to match a room’s theme.

6. Why Choose MYounglaser CO2 Laser Machines for Acrylic Design?

MYounglaser’s CO2 laser machines provide industry-leading precision, cooling systems, and versatility needed for interior design projects. With customizable settings and advanced features, these machines enable you to work confidently with acrylic, no matter the complexity of your design. MYounglaser machines are also engineered for reliability, making them a dependable investment for designers looking to produce high-quality, professional-grade acrylic decor.

Ready to elevate your interior design projects with MYounglaser CO2 laser machines? Discover how these machines can help you create unique, high-impact acrylic designs effortlessly. Contact us to learn more and find the best CO2 laser machine for your needs!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

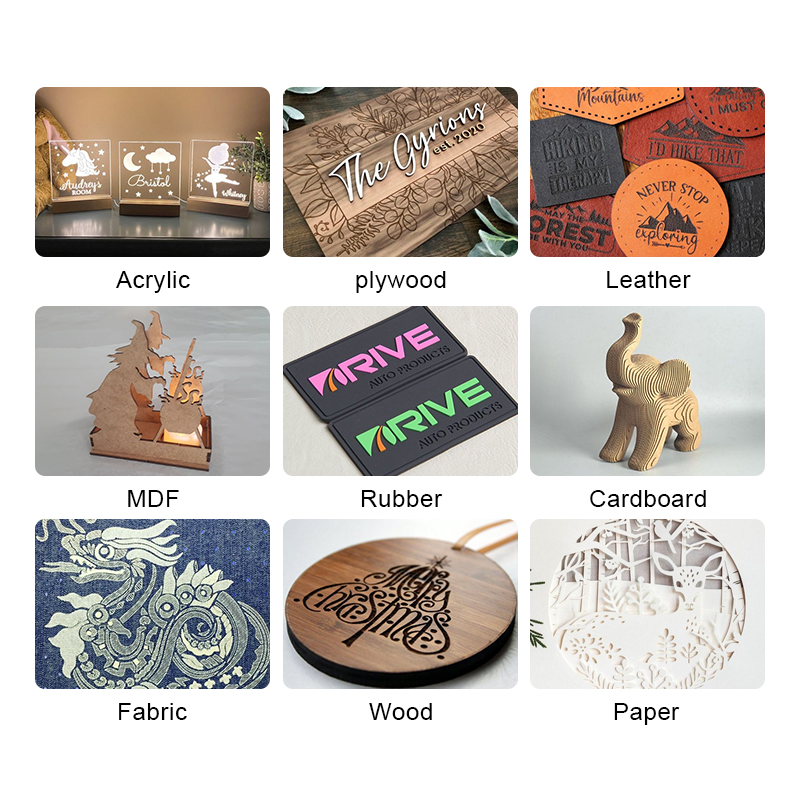

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.