INDUSTRIAL NEWS

Recycling Acrylic Scraps from CO2 Laser Projects

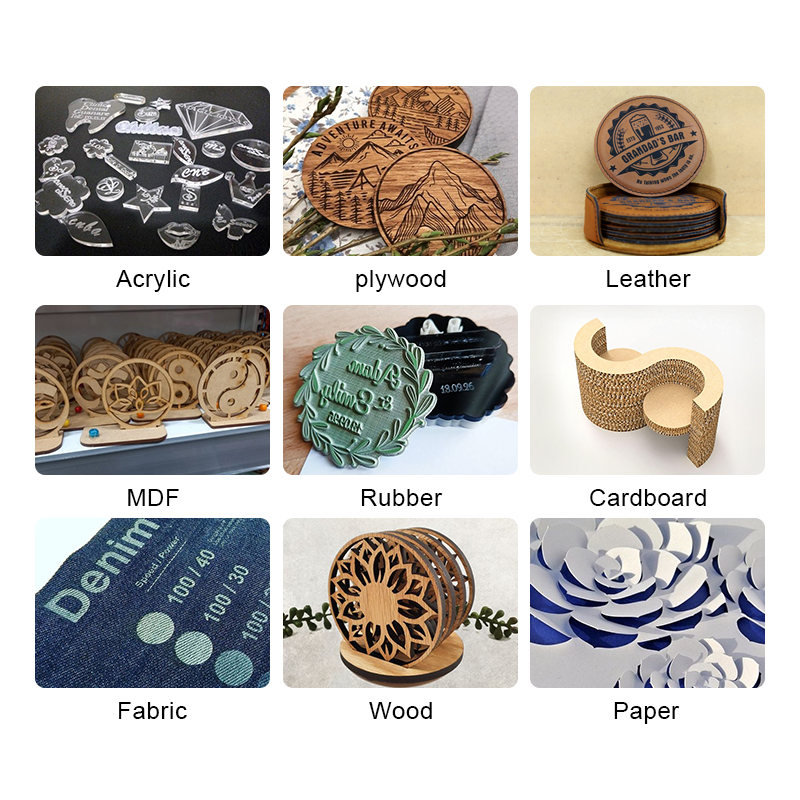

As the popularity of CO2 laser machines grows, so does the need for sustainable practices in laser cutting projects. Acrylic, a versatile and commonly used material in these projects, often leaves behind scraps that can add up to significant waste. However, with innovative recycling methods, these remnants can be repurposed, reducing environmental impact and maximizing material use.

Why Recycle Acrylic Scraps?

- Environmental Benefits: Acrylic is non-biodegradable, and discarding it contributes to landfill waste. Recycling helps reduce this burden.

- Cost Efficiency: Repurposing scraps minimizes the need to purchase new materials, cutting project costs.

- Creativity Boost: Smaller pieces of acrylic can inspire innovative designs or be used for prototypes.

Creative Uses for Acrylic Scraps

1. Jewelry and Accessories

Small acrylic pieces can be crafted into:

- Earrings, necklaces, and bracelets with unique shapes.

- Keychains and bag charms using vibrant or patterned acrylic.

2. Mosaic Art

Combine various colors and textures of acrylic scraps to create artistic mosaics for home decor or art installations.

3. Educational Tools

Designers can use smaller pieces to create:

- Templates for teaching geometric shapes.

- Scaled-down prototypes for projects.

4. Functional Items

Turn scraps into practical items such as:

- Coasters.

- Small acrylic stands or phone holders.

Recycling Methods for Acrylic Scraps

1. Industrial Recycling

Acrylic manufacturers or specialized recycling centers can process acrylic scraps into reusable sheets or pellets.

2. Laser Reuse

Use your MYounglaser CO2 laser machine to transform scraps into small, precise products, ensuring no material goes to waste.

3. DIY Solutions

Melt down smaller acrylic pieces (with proper ventilation and safety) to create new acrylic sheets for further use.

MYounglaser: Supporting Sustainable Laser Cutting

MYounglaser CO2 laser machines provide the precision and flexibility needed to work efficiently with acrylic, minimizing waste. Their advanced systems allow for detailed cutting, ensuring maximum material utilization with minimal offcuts.

Why Choose MYounglaser?

- Durability: Machines built to handle frequent use without compromising quality.

- Precision: Cuts acrylic accurately, reducing leftover scraps.

- Sustainability: Ideal for designers focusing on eco-friendly practices.

Recycling acrylic scraps is not only an eco-friendly approach but also a creative opportunity to explore innovative designs. With a reliable CO2 laser machine like those offered by MYounglaser, you can achieve precision, reduce waste, and contribute to a sustainable future in laser cutting.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.