INDUSTRIAL NEWS

Acrylic vs. Polycarbonate: Which Material Works Best for CO2 Lasers?

When working with CO2 laser machines, selecting the right material can significantly affect the quality of your cuts and engravings. Acrylic and polycarbonate are two popular choices for laser cutting, each with its unique properties. In this article, we’ll compare both materials to help you determine which works best for your laser cutting projects.

Acrylic: Versatile and Aesthetic

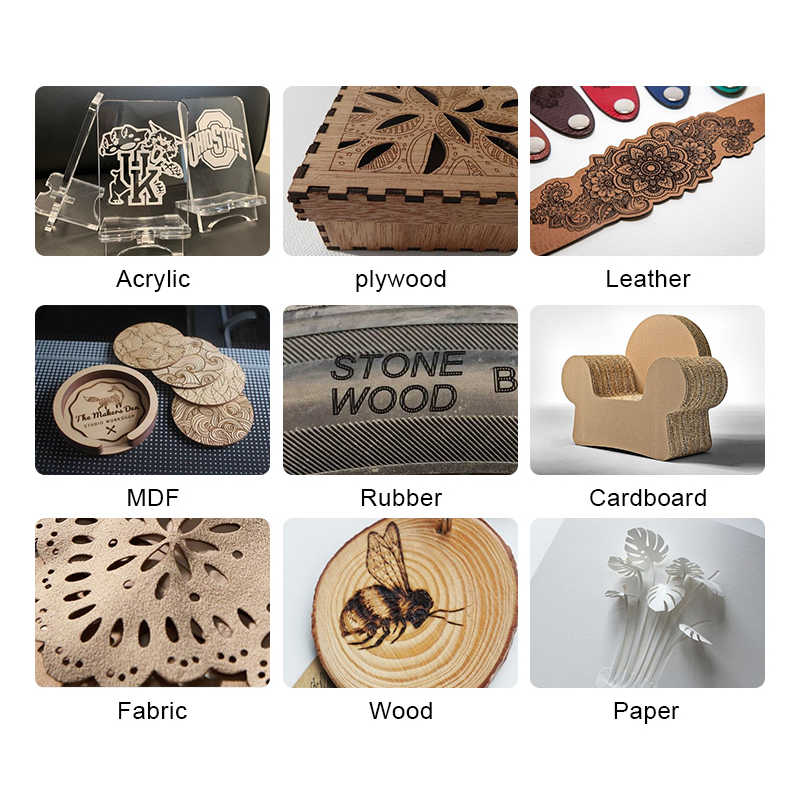

Acrylic is a widely used material in laser cutting due to its versatility and aesthetic qualities. Here are some reasons why acrylic is ideal for CO2 laser machines:

- Cutting Quality: Acrylic cuts cleanly and precisely with CO2 laser machines like those offered by MYounglaser. It leaves smooth edges that often don’t require additional finishing.

- Engraving: Cast acrylic, in particular, produces crisp engravings with a frosted appearance, making it ideal for decorative and signage applications.

- Variety: Acrylic is available in both clear and colored sheets, making it a popular choice for creating aesthetically pleasing designs, from displays to awards and furniture.

- Thickness Range: With a CO2 laser machine, acrylic can be cut in thicknesses ranging from 1mm to 30mm depending on the machine’s power.

Pros of Acrylic:

- Precise, clean cuts

- Easy to engrave

- Available in various colors and finishes

- Cost-effective

Cons:

- Prone to cracking under high impact

- May discolor if improperly cut or if exposed to UV light over time

Polycarbonate: Strong but Tricky

Polycarbonate is known for its strength and impact resistance, often used in industries requiring durable materials. However, it presents challenges when used with CO2 lasers.

- Cutting Issues: Unlike acrylic, polycarbonate does not cut cleanly with a CO2 laser. It tends to char, melt, and leave unsightly edges that require post-processing. The material also releases toxic fumes when cut, requiring effective ventilation systems.

- Limited Applications: Due to these cutting challenges, polycarbonate is not typically recommended for intricate or decorative laser cutting. However, it may still be used for projects that require high durability and impact resistance, such as safety shields or industrial components.

Pros of Polycarbonate:

- Extremely durable and impact-resistant

- High strength-to-weight ratio

- Flame retardant properties

Cons:

- Poor laser cutting quality

- Releases toxic fumes when cut

- Melts and leaves rough edges

Which Material is Best for CO2 Laser Machines?

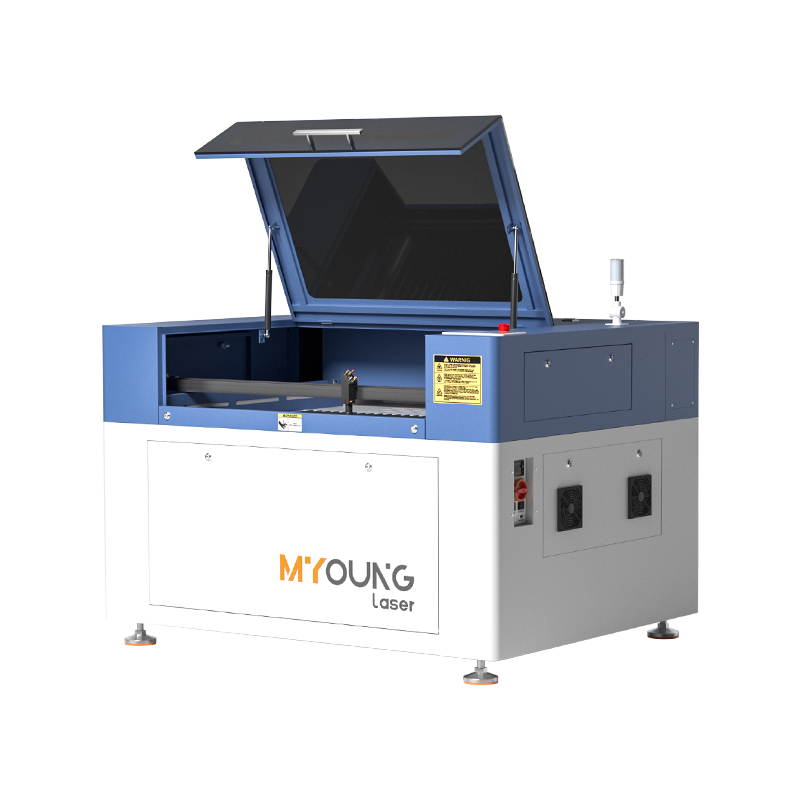

For most CO2 laser cutting projects, acrylic is the superior material due to its clean cuts, ease of engraving, and wide range of applications. MYounglaser CO2 laser machines, designed with precision and power, are ideal for cutting and engraving acrylic sheets, making them the go-to choice for hobbyists and professionals alike.

Polycarbonate, on the other hand, is not well-suited for laser cutting unless specific properties such as impact resistance are required. Even then, you may need to consider alternative cutting methods to avoid the challenges posed by CO2 lasers.

In the battle between acrylic and polycarbonate for CO2 laser machines, acrylic emerges as the clear winner for clean cuts, versatile applications, and ease of use. If you’re looking for reliable CO2 laser machines, consider the MYounglaser Dura series, which offers the precision and features needed to work with acrylic effortlessly. Whether you’re a business looking to produce intricate designs or a hobbyist working on creative projects, MYounglaser machines provide excellent results with acrylic.

Contact us today to explore the best CO2 laser machines for your acrylic cutting needs and take your projects to the next level!