Acrylic Laser Cutting Machines: Enhance Your Craft with Myoung Budget Series

INDUSTRIAL NEWS

Acrylic, often known as Plexiglas or Perspex, is a versatile plastic material that is widely used in various industries due to its clarity, strength, and ease of fabrication. Acrylic is a transparent thermoplastic homopolymer, often mistaken for polycarbonate due to its high impact resistance. It’s a popular alternative to glass, offering lightweight and shatter-resistant properties, making it ideal for numerous applications.

Key Features of Acrylic

Clarity and Transparency: Acrylic is known for its excellent optical clarity and transparency, making it a popular choice for applications where a clear view is essential, such as display cases, windows, and aquariums.

Strength and Durability: Despite being half the weight of glass, acrylic is up to 17 times more impact-resistant. This makes it an excellent material for safety glazing, protective barriers, and other high-impact environments.

Weather Resistance: Acrylic is highly resistant to the elements, maintaining its clarity and strength in both indoor and outdoor applications, making it suitable for signage, skylights, and architectural glazing.

Ease of Fabrication: Acrylic can be easily cut, drilled, formed, and glued, allowing for complex and precise shapes to be manufactured with laser cutting machines.

Applications of Acrylic

Acrylic is used in a wide range of industries due to its adaptability and robustness:

Advertising and Signage: Acrylic is commonly used for illuminated signs, point-of-sale displays, and advertising boards due to its ability to diffuse light evenly and maintain vibrant colors.

Architecture and Interior Design: Its lightweight nature and weather resistance make acrylic ideal for windows, partitions, skylights, and decorative panels.

Automotive and Aerospace: Acrylic is used for windows, windshields, and other components where transparency and durability are required.

Furniture and Home Decor: Acrylic furniture and home accessories are popular for their modern aesthetic and durability.

How Acrylic Laser Cutting Machines Work

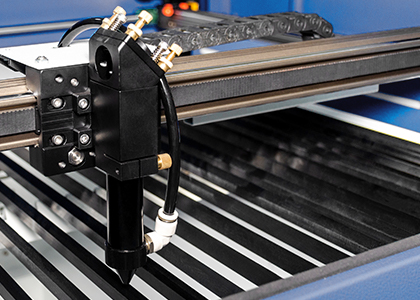

Laser Technology: Acrylic laser cutting machines typically use CO2 lasers, which are highly effective for cutting and engraving acrylic materials. The laser emits a beam that melts, burns, or vaporizes the material, resulting in precise cuts with smooth edges.

Cutting Process: The machine’s software is used to design and control the cutting path. The laser head moves over the acrylic sheet based on the programmed design, allowing for intricate patterns and detailed engravings.

Advantages of Using Acrylic Laser Cutting Machines

Precision and Accuracy: Laser cutters provide extremely accurate cuts with tight tolerances, making them ideal for detailed designs and complex shapes.

High-Quality Finish: The laser produces smooth, polished edges without the need for additional finishing processes, saving time and labor.

Versatility: These machines can cut various thicknesses of acrylic and are suitable for both small-scale projects and large industrial applications.

Speed and Efficiency: Laser cutting is faster than traditional methods and can process multiple pieces in a single run, increasing productivity.

Non-Contact Process: Since there is no direct contact between the machine and the material, there is minimal risk of damaging the acrylic during the cutting process.

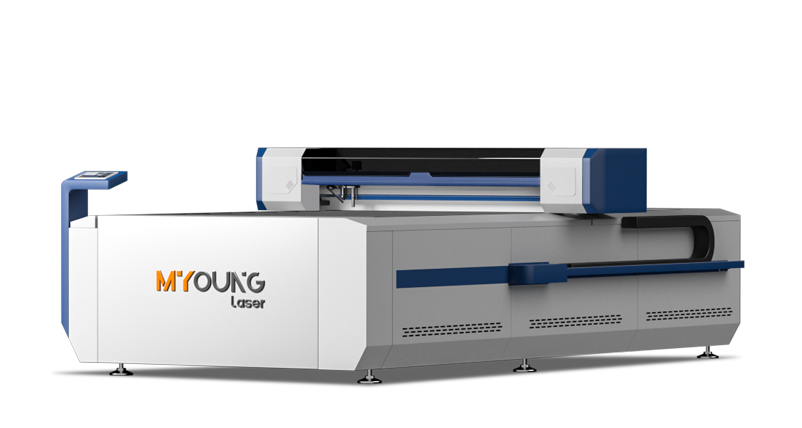

Integrating the Myoung Budget Series into Acrylic Applications

The Myoung Budget Series laser cutting machines are designed to maximize the potential of acrylic materials, making them perfect for both personal and professional use. Here’s how the Budget Series stands out when working with acrylic:

120-Degree Overhead Camera: This feature allows for precise positioning of designs on acrylic sheets, reducing waste and ensuring perfect alignment.

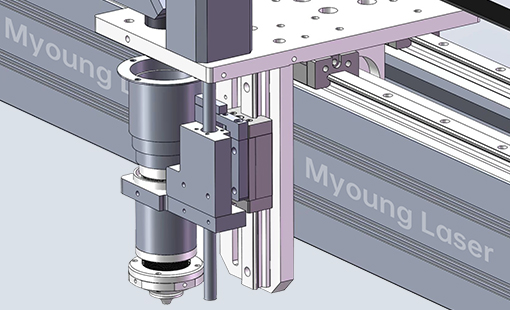

High-Speed Rail and Lightweight Laser Head: Achieving engraving speeds of up to 1900mm/s, this setup ensures rapid production without sacrificing quality, perfect for high-volume acrylic signage and display production.

Compact All-in-One Design: The integration of an air compressor, water chiller, and extraction fan ensures that acrylic cutting and engraving are smooth and clean, with minimal workspace requirements.

Software-Controlled Air Assist: This allows for precise control over cutting and engraving settings, producing clean edges and minimizing heat marks on acrylic surfaces.

Automatic Focusing Laser Head: Quickly adjust to different acrylic thicknesses, enhancing safety and reducing setup times, ideal for varied and complex projects.

In-Line Beam Combiner: Simplifies setup and maintenance, allowing for uninterrupted focus on creating detailed acrylic pieces.

Commercial-Grade Steel Enclosure: Provides stability and reduces vibrations, ensuring accuracy and quality in every cut and engraving.

Generous Z-Axis Travel: Accommodates larger acrylic pieces and rotary engraving, expanding creative possibilities.

Durable Machine Cabinet: Ensures long-term reliability and performance, making the Budget Series a valuable investment for both hobbyists and businesses.

With a price range of $2,000 to $3,000, the Myoung Budget Series laser machines offer exceptional value for their advanced features and robust design, making them the ideal choice for anyone working with acrylic materials. Whether you’re creating intricate designs for home decor or manufacturing commercial signage, these machines provide the precision and efficiency you need.

Contact us today to learn more about how the Myoung Budget Series can transform your acrylic projects and elevate your craft to new heights.