Future Trends in the Chinese CO2 Laser Engraving Industry

Our stories

Future Trends in the Chinese CO2 Laser Engraving Industry

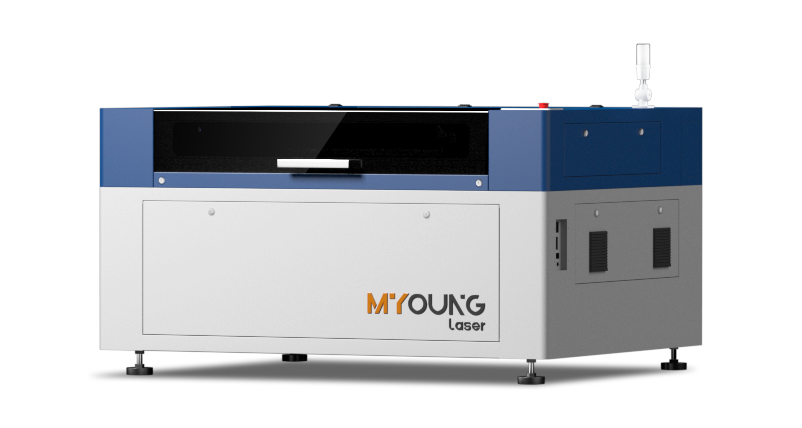

The Chinese CO2 laser engraving industry is poised for significant growth and transformation in the coming years. Several key trends are expected to shape its future:

1. Technological Advancements

- Integration of AI and Automation: The incorporation of artificial intelligence and automation into CO2 laser engraving machines is set to revolutionize the industry. These technologies will enhance precision, optimize workflows, and reduce human error, leading to higher efficiency and productivity .

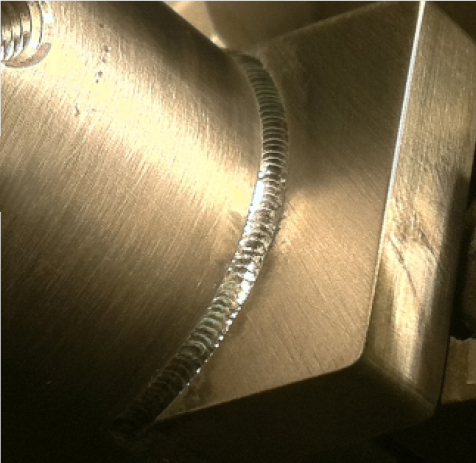

- Improved Laser Sources: Innovations in laser technology, such as the development of more powerful and efficient laser sources, will allow for faster and more precise engraving. This includes advancements in laser tube design and cooling systems .

2. Material Compatibility and Versatility

- Expanded Material Capabilities: Future CO2 laser engraving machines will be designed to work with an even broader range of materials, including more advanced composites and emerging materials used in high-tech industries .

- Hybrid Machines: The development of hybrid machines that combine CO2 lasers with other types of lasers (e.g., fiber lasers) to enhance versatility and performance across different materials is another trend to watch .

3. Enhanced Software and User Interfaces

- Advanced Software Solutions: The integration of more sophisticated software solutions will provide better design capabilities, user-friendly interfaces, and improved machine control. Features such as real-time monitoring, predictive maintenance, and cloud-based management systems are expected to become standard .

- Customizable Interfaces: User interfaces will become more customizable, allowing operators to tailor the controls and displays to their specific needs and preferences, improving usability and efficiency .

4. Sustainability and Eco-friendliness

- Energy Efficiency: Future CO2 laser engraving machines will focus on reducing energy consumption through more efficient power sources and better thermal management. This will not only lower operational costs but also reduce the environmental impact .

- Eco-friendly Materials and Processes: Manufacturers will increasingly adopt eco-friendly materials and processes, such as the use of recyclable components and environmentally safe manufacturing practices, to appeal to a growing segment of eco-conscious consumers .

5. Increased Customization and Personalization

- Bespoke Solutions: As consumer demand for personalized products continues to rise, CO2 laser engraving machines will offer more customization options, allowing businesses to provide tailored solutions to their clients .

- Mass Customization: The ability to efficiently produce small batches of customized products will become a significant competitive advantage, driven by advancements in laser technology and production techniques .

6. Global Market Expansion

- Export Growth: Chinese manufacturers are expected to expand their presence in international markets by offering competitively priced, high-quality CO2 laser engraving machines. This expansion will be supported by improvements in global logistics and supply chains .

- Strategic Partnerships: Forming strategic partnerships with international companies will help Chinese manufacturers to gain a foothold in new markets and leverage local expertise to better serve regional customers .