Marketing Tips for Selling Laser-Cut Acrylic Products

INDUSTRIAL NEWS

Marketing Tips for Selling Laser-Cut Acrylic Products

Selling laser-cut acrylic products is a lucrative venture, as the demand for customized, intricate designs grows across industries like interior décor, fashion, and corporate gifting. Leveraging effective marketing strategies can help you reach your target audience and boost sales. Here’s how you can strategically market your laser-cut acrylic products with the help of reliable CO2 laser machines like MYounglaser.

1. Understand Your Market

Identify Your Audience

Knowing who will buy your products is critical. Common audiences include:

- Interior Designers: Custom acrylic panels and décor items.

- Retail Businesses: Point-of-sale displays and signage.

- Gift Shoppers: Personalized items such as keychains and plaques.

Research Competitors

Study other sellers to understand what products perform well, pricing trends, and areas you can innovate.

2. Focus on Product Presentation

Highlight Features

Showcase the precision, durability, and elegance of your laser-cut acrylic items. Emphasize how using MYounglaser CO2 laser machines ensures top-quality cuts and intricate designs.

Professional Photos

Invest in high-quality photography to capture the beauty of your products. Use clean backgrounds and lighting that accentuates the acrylic’s transparency and details.

3. Optimize Your Online Presence

Website

Create a professional website featuring:

- A catalog with detailed product descriptions and prices.

- Testimonials that build trust and showcase customer satisfaction.

- SEO-optimized content using keywords like CO2 laser machine, MYounglaser, CO2 laser machine suppliers, acrylic CO2 laser cutting machine.

Social Media

Leverage visual platforms such as Instagram and Pinterest. Share:

- Videos of the laser-cutting process.

- Customer stories showcasing your products in real-world settings.

E-Commerce Platforms

List your products on platforms like Etsy, Amazon Handmade, or Alibaba to reach broader audiences.

4. Highlight Customization Options

Customizability is a key selling point. Let customers know they can personalize items such as:

- Engraved names or logos.

- Custom shapes or designs.

Explain how your acrylic CO2 laser cutting machine can handle unique requests with precision and speed.

5. Collaborate with Other Businesses

B2B Partnerships

Partner with event organizers, retailers, and interior design firms for bulk orders.

Co-Branding

Work with local businesses to create co-branded items like branded acrylic signage or giveaways.

6. Offer Discounts and Incentives

- Seasonal Sales: Launch holiday promotions for customized gifts.

- Bundle Deals: Offer packages for multiple items.

- Referral Rewards: Encourage word-of-mouth marketing by rewarding loyal customers who refer new clients.

7. Educate Your Audience

Create Content

Build authority by publishing content such as:

- Tutorials on laser-cutting projects.

- Blogs about the versatility of acrylic in design.

For instance, an article titled “Top Creative Ideas for Acrylic Laser Cutting” can attract potential buyers and establish your expertise.

Host Workshops

Engage your local community by hosting DIY laser-cutting workshops, showcasing your products and machinery.

8. Leverage Email Marketing

Regular newsletters can keep customers updated about:

- New product launches.

- Special promotions.

- Tips and tricks for maintaining laser-cut acrylic items.

9. Use Analytics to Refine Strategies

Track performance metrics for your website, ads, and social media. Use insights to optimize your campaigns and focus on strategies that generate the best ROI.

10. Why Choose MYounglaser for Your Acrylic Products?

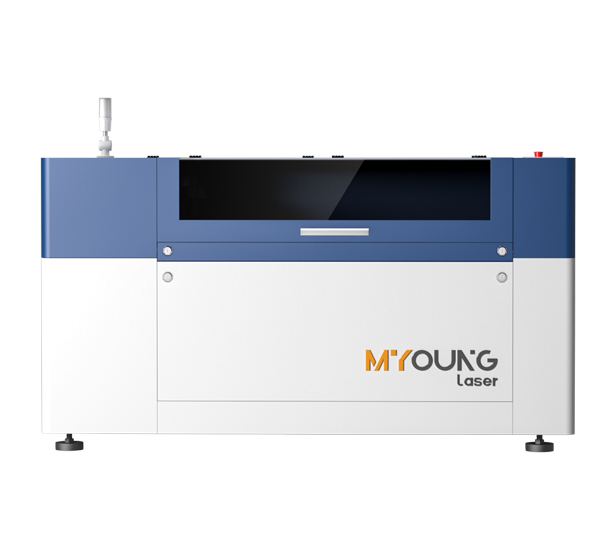

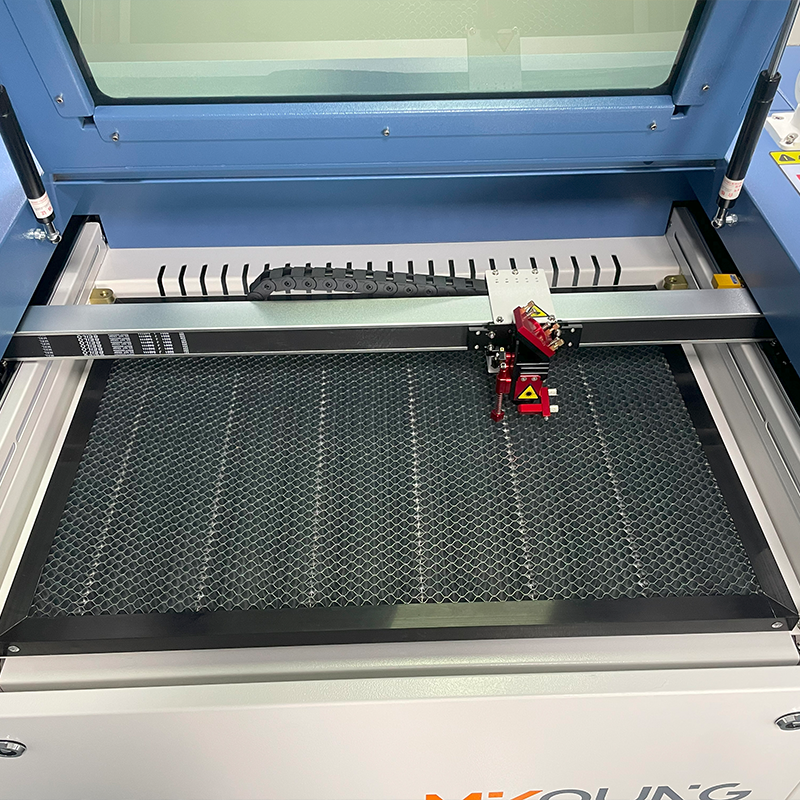

Investing in a high-quality CO2 laser machine, like those from MYounglaser, ensures your business delivers exceptional products. Key benefits include:

- High Precision: Perfect for intricate designs and cuts.

- Reliability: Machines built for long-term performance.

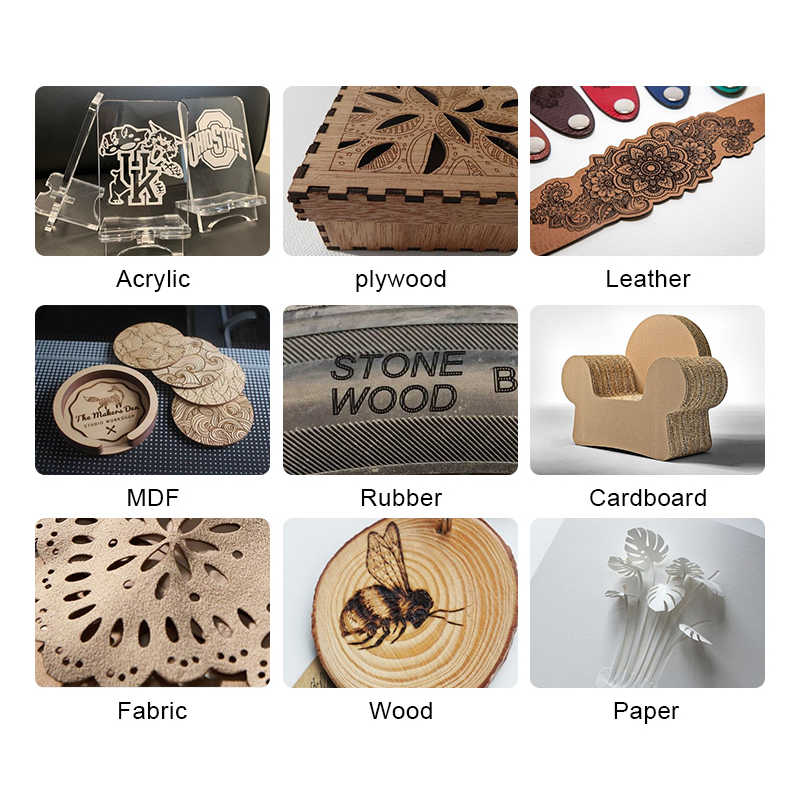

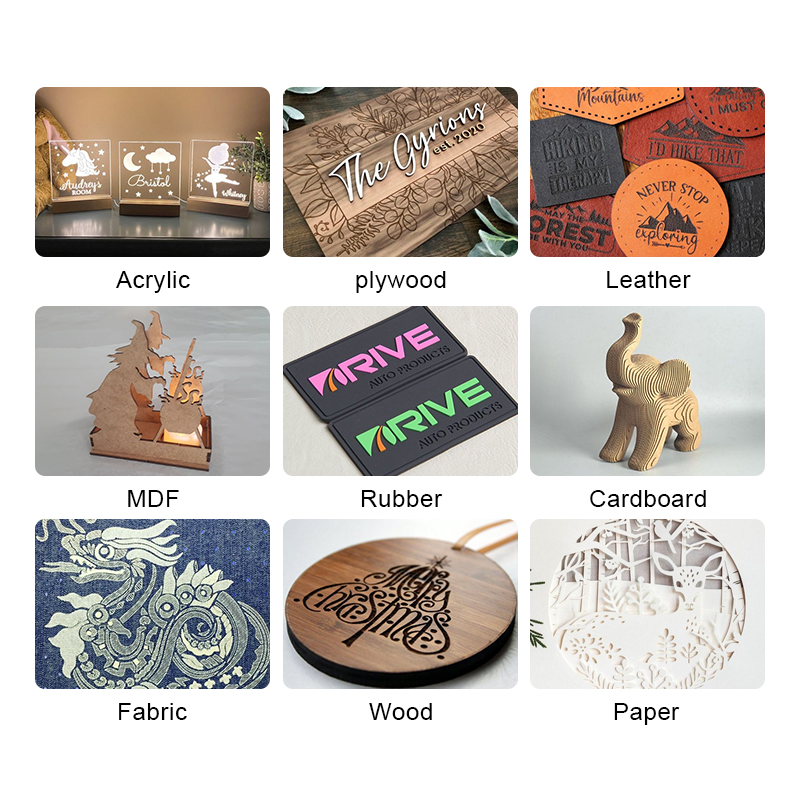

- Versatility: Handles acrylic and a wide range of other materials with ease.

Explore the MYounglaser lineup to find the best CO2 laser machine for your business needs.

Marketing laser-cut acrylic products requires a blend of creativity, strategy, and the right tools. With a well-defined target market, compelling product presentation, and robust online presence, you can position your business as a leader in this niche. Partnering with MYounglaser CO2 laser machine suppliers ensures you’re equipped with the technology needed to meet customer expectations and scale your business.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.