Top Software for Acrylic CO2 Laser Cutting Designs

INDUSTRIAL NEWS

Top Software for Acrylic CO2 Laser Cutting Designs

When creating intricate designs for acrylic CO2 laser cutting, the right software is essential. From drawing layouts to setting specific cutting parameters, professional design software can make the entire process efficient and precise. Here’s a guide to some of the top software that works well with MYounglaser CO2 machines and other leading brands, helping you achieve high-quality results in acrylic laser cutting.

1. Adobe Illustrator

- Overview: Adobe Illustrator is a favorite among designers for vector graphic creation. It’s great for preparing detailed and intricate designs, thanks to its advanced vector editing tools.

- Why it Works: Since laser cutters read vector files, Illustrator’s ability to create precise vector paths makes it ideal for laser cutting. Exporting to compatible formats like SVG and DXF is simple, allowing seamless transition to laser software.

- Best Use: Creating intricate designs, fine engravings, and detailed cutouts for acrylic.

2. CorelDRAW

- Overview: Known for its versatility, CorelDRAW is widely used in the laser cutting industry. Many CO2 laser machine suppliers endorse it due to its robust tools for preparing laser-ready files.

- Why it Works: CorelDRAW’s design tools support a range of file formats and allow for precise color control, which helps when setting up vector paths and engraving designs.

- Best Use: Crafting logos, signage, and custom engravings on acrylic sheets.

3. AutoCAD

- Overview: AutoCAD is known for its engineering precision, making it an excellent choice for industrial laser cutting designs.

- Why it Works: It allows users to draw highly precise designs and export them in DXF or DWG formats, which are compatible with most CO2 laser machines. AutoCAD’s interface also supports exact measurements, essential for projects requiring precise cuts.

- Best Use: Industrial design projects where accuracy and tight tolerances are critical, such as structural acrylic components.

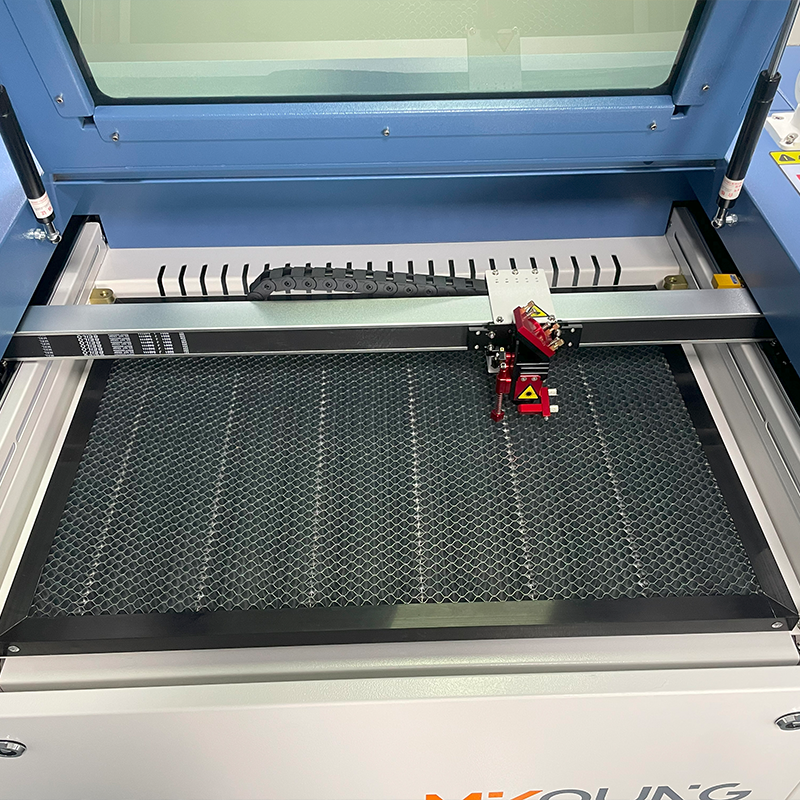

4. Choosing the Wrong Acrylic Type

Extruded acrylic and cast acrylic behave differently under a laser. Using the wrong type can lead to issues with cutting quality and edge finish.

- Solution: For intricate or high-quality projects, opt for cast acrylic, as it produces cleaner cuts and is less prone to burning. MYounglaser machines are versatile and capable of handling both types, but cast acrylic generally delivers superior results.

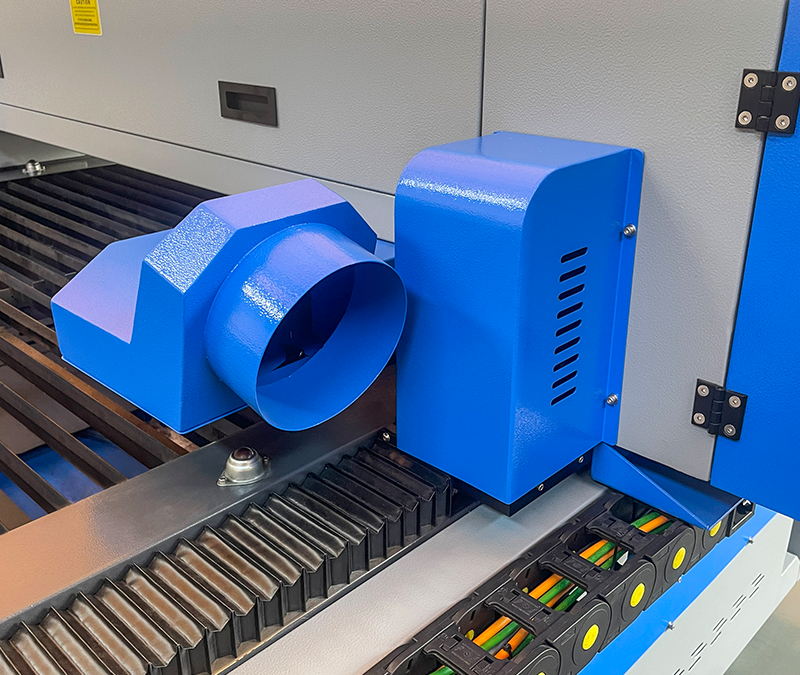

5. Lack of Ventilation

Poor ventilation can lead to an accumulation of fumes, which not only affects visibility but can also cause burns and imperfections.

- Solution: Ensure your workspace has a powerful exhaust system to clear out fumes during operation. Effective ventilation is key to maintaining cut quality and protecting your laser machine components from buildup.

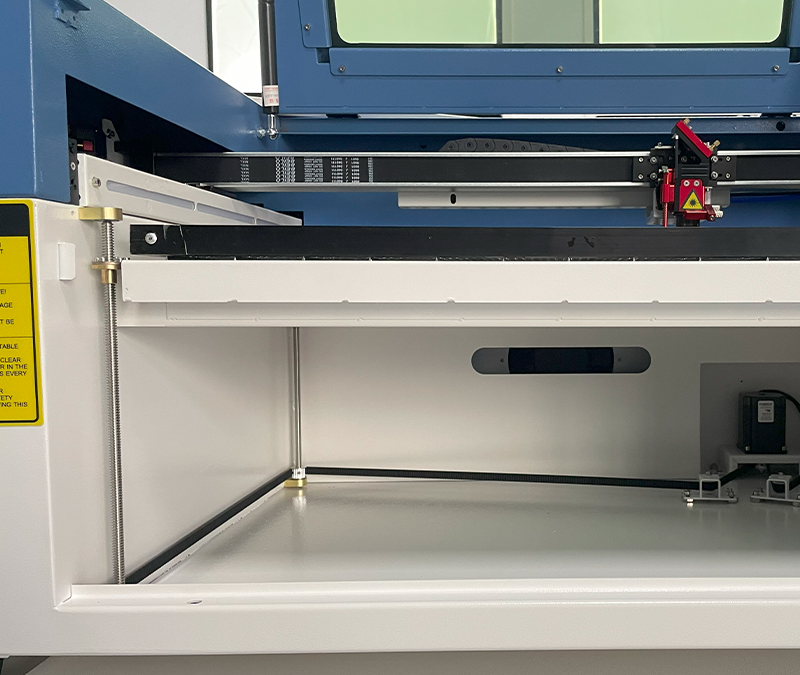

6. Neglecting Regular Maintenance

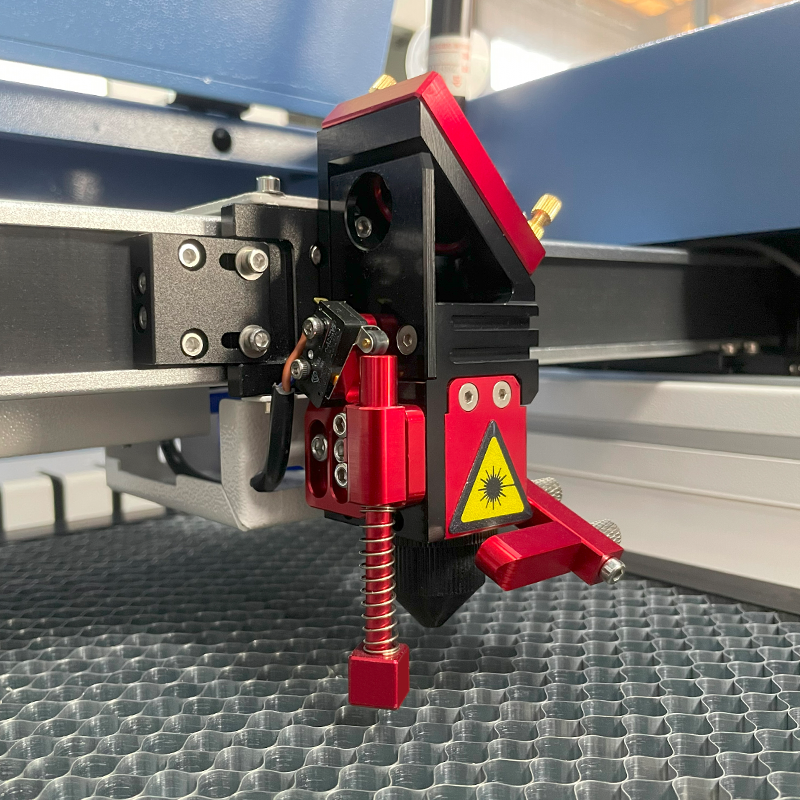

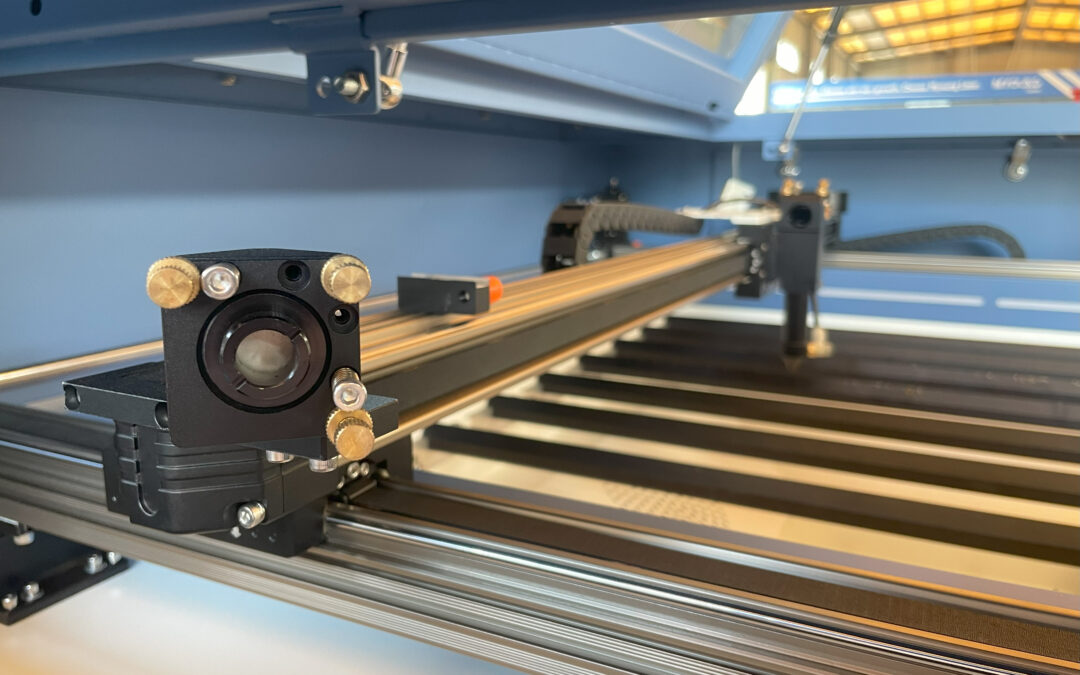

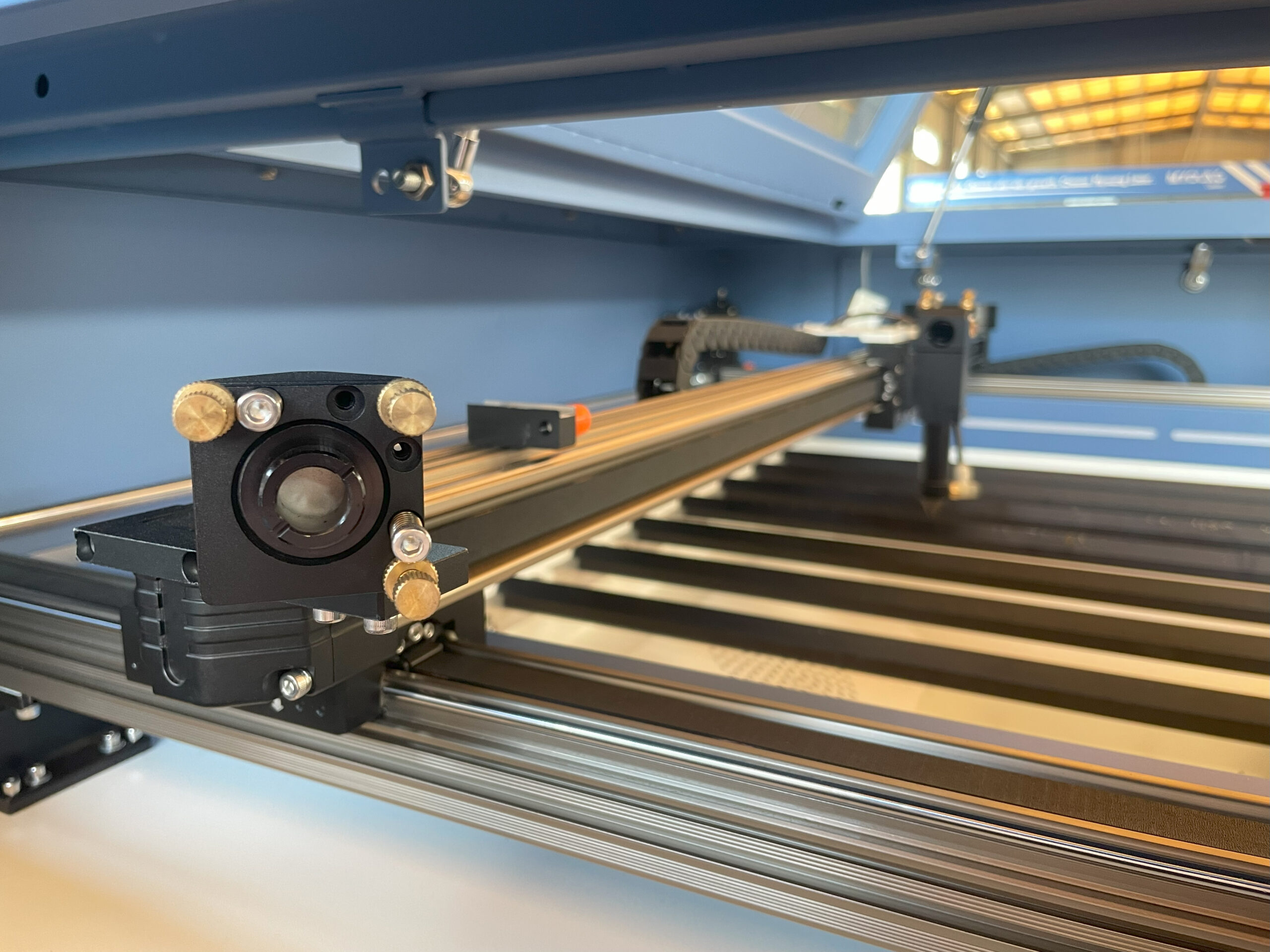

Dirty lenses and mirrors can interfere with the laser’s power and precision, leading to poor performance and potential damage to the material.

- Solution: Clean the lenses and mirrors regularly and check for alignment. This maintenance is especially important for acrylic CO2 laser cutting machines since acrylic can produce residue that clouds the optics.

Choosing the Right Software for MYounglaser CO2 Machines

Selecting the right design software depends on the complexity of your projects, budget, and familiarity with design tools. Here’s a quick overview to guide your choice:

- For Beginners: Inkscape offers a solid starting point without financial commitment, making it accessible and practical.

- For Professional Designs: Adobe Illustrator and CorelDRAW provide comprehensive design tools and professional output quality, ideal for complex or intricate acrylic projects.

- For Direct Laser Control: LightBurn and RDWorks allow for seamless integration with CO2 laser machines, giving you precise control over laser settings.

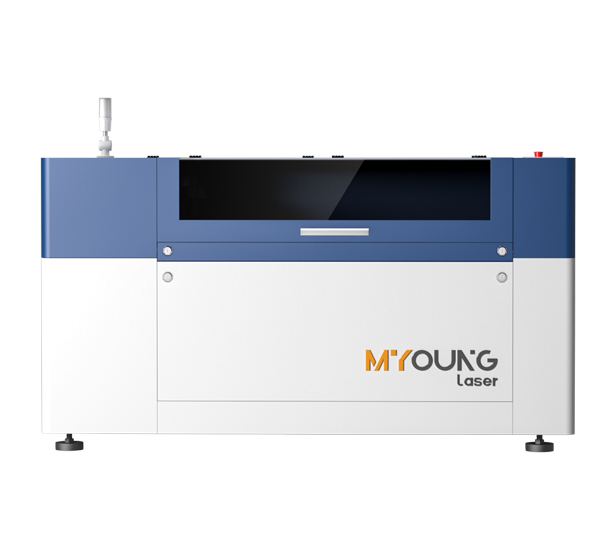

Bring Your Acrylic Designs to Life with MYounglaser

Choosing the right software for your acrylic CO2 laser cutting machine can transform your workflow and final results. With high-quality machines like MYounglaser, paired with industry-leading design software, your acrylic projects can achieve precision, efficiency, and creativity.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.