Creative Business Ideas with Acrylic CO2 Laser Machines

INDUSTRIAL NEWS

Creative Business Ideas with Acrylic CO2 Laser Machines

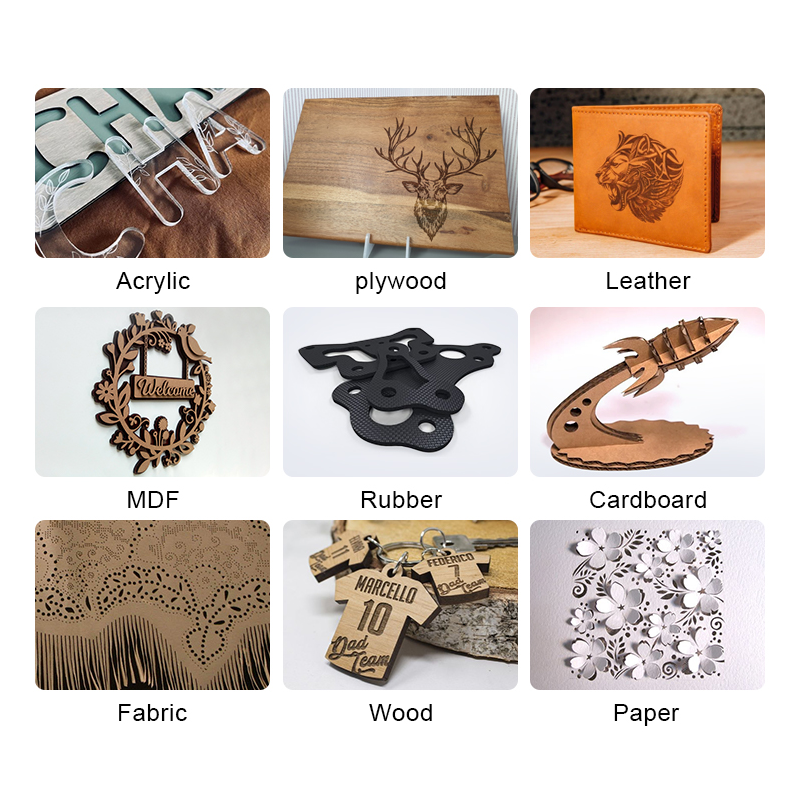

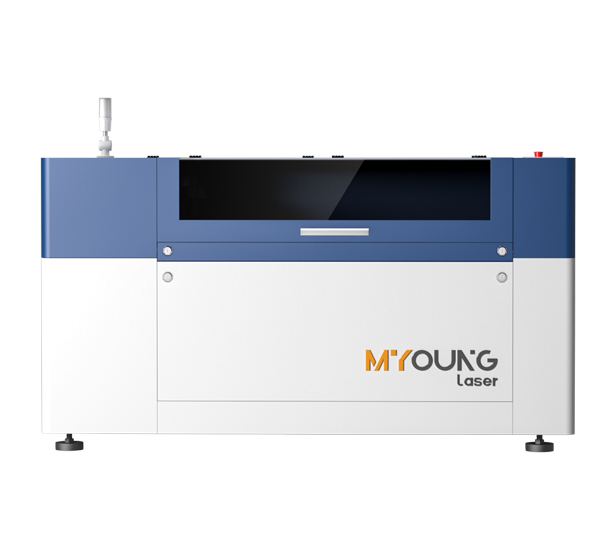

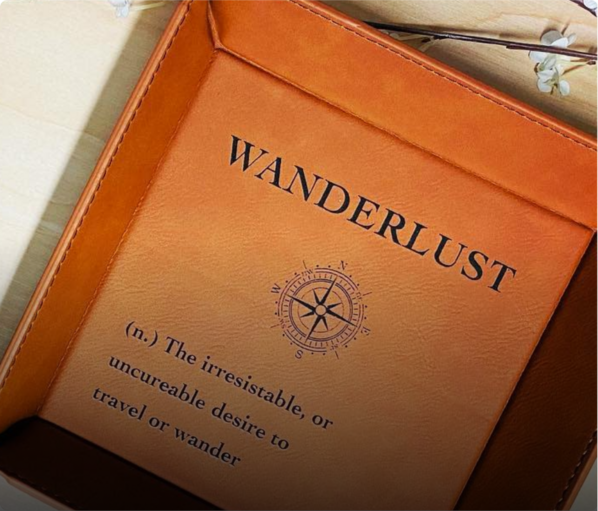

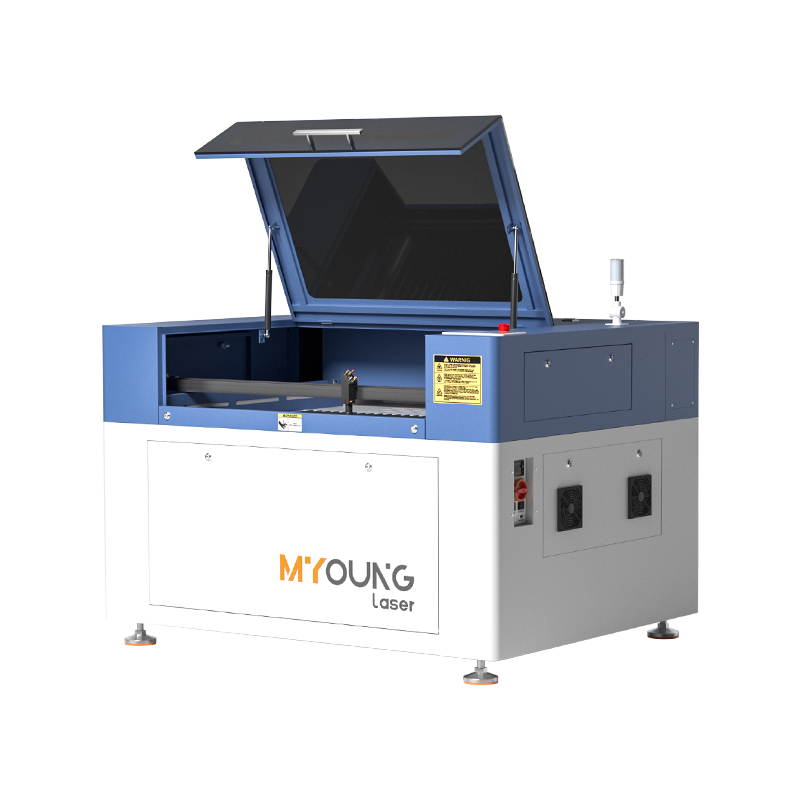

Acrylic CO2 laser machines offer incredible versatility and precision, opening up a world of business opportunities. Whether you’re a budding entrepreneur or looking to expand your product range, using acrylic and a CO2 laser machine can lead to innovative, high-margin ventures. In this article, we’ll explore some creative business ideas that can thrive with the help of MYounglaser acrylic CO2 laser cutting machines.

1. Custom Signage and Displays

One of the most popular uses for acrylic CO2 laser cutting is in the creation of custom signage and displays. The ability to precisely cut intricate designs, logos, and text from acrylic sheets allows businesses to offer highly personalized products. These can be sold to:

- Retail Stores: Custom logo signs, promotional displays, and shelf decorations.

- Weddings & Events: Personalized nameplates, wedding signage, and table numbers.

- Offices: Branded nameplates and desk signs.

With a MYounglaser CO2 laser machine, you can achieve fine cuts and engravings, ensuring high-quality results that stand out in a crowded market.

2. Home Décor and Accessories

The demand for unique, custom home décor items is continuously growing, and acrylic lends itself perfectly to modern design trends. Using a CO2 laser machine, you can create:

- Wall Art: Custom acrylic wall hangings with intricate patterns or personalized messages.

- Lamps and Lighting Fixtures: Laser-cut acrylic lampshades or decorative light fixtures.

- Mirrors and Frames: Custom mirror frames with elaborate engravings or designs.

The precision of MYounglaser CO2 machines ensures that even the most complex patterns are cut cleanly, making these home décor items not only aesthetically pleasing but also durable and of high quality.

3. Personalized Gifts and Awards

Offering personalized gifts can be a lucrative niche, and laser-cut acrylic products are perfect for this. You can create a range of custom products such as:

- Trophies and Awards: Custom-engraved awards for corporate or school events.

- Keychains and Ornaments: Small, personalized acrylic keychains and ornaments, perfect for gifts or promotional items.

- Photo Frames: Unique, engraved acrylic photo frames for personal or corporate gifting.

Thanks to the MYounglaser CO2 laser machine, you can provide a high level of customization, allowing your business to stand out in the personalized gift market.

4. Jewelry and Fashion Accessories

Acrylic is a lightweight yet durable material, making it ideal for fashion accessories. With a CO2 laser machine, you can create custom jewelry, including:

- Earrings, Necklaces, and Bracelets: Intricate acrylic designs that are trendy and affordable.

- Pins and Brooches: Fun, personalized designs for pins or brooches that appeal to a younger audience.

- Fashion Accessories: Laser-cut acrylic hair accessories, sunglasses, or other stylish products.

MYounglaser machines allow for detailed cutting, ensuring that your products are fashionable and of top-notch quality.

5. Architectural Models and Prototypes

For architects and designers, acrylic CO2 laser machines can be invaluable tools for creating scale models and prototypes. Using these machines, you can create:

- Detailed Models: Precise, intricate models of buildings or structures for presentations.

- Prototype Parts: Custom, laser-cut parts for various industries like electronics, engineering, or interior design.

The MYounglaser CO2 laser machine provides the accuracy needed for creating professional-grade models and prototypes.

6. Custom Phone and Gadget Accessories

With the ever-growing popularity of gadgets, creating custom accessories like phone cases, stands, or holders made from acrylic can be highly profitable. You can offer:

- Custom-Engraved Phone Cases: Personalized acrylic phone cases with custom designs, names, or artwork.

- Tablet and Phone Stands: Sleek and modern acrylic stands for phones, tablets, or laptops.

- Custom Device Holders: Unique, laser-cut holders or docks for charging stations or gadgets.

MYounglaser CO2 laser machines ensure that you can produce high-quality, visually appealing, and functional accessories.

7. Educational Tools and Learning Aids

Acrylic can be used to create educational tools and teaching aids. You can start a business that supplies schools, universities, and educational institutions with:

- Laser-Cut Puzzle Pieces: Educational puzzles for young children made from safe, durable acrylic.

- Learning Tools: Custom acrylic learning aids such as alphabet cutouts, number sets, or geometry tools.

- Classroom Decorations: Custom-engraved acrylic decorations for classrooms, including nameplates, wall art, and motivational quotes.

With the precision and versatility of MYounglaser CO2 laser machines, your educational products will stand out for their quality and durability.

Why Choose MYounglaser?

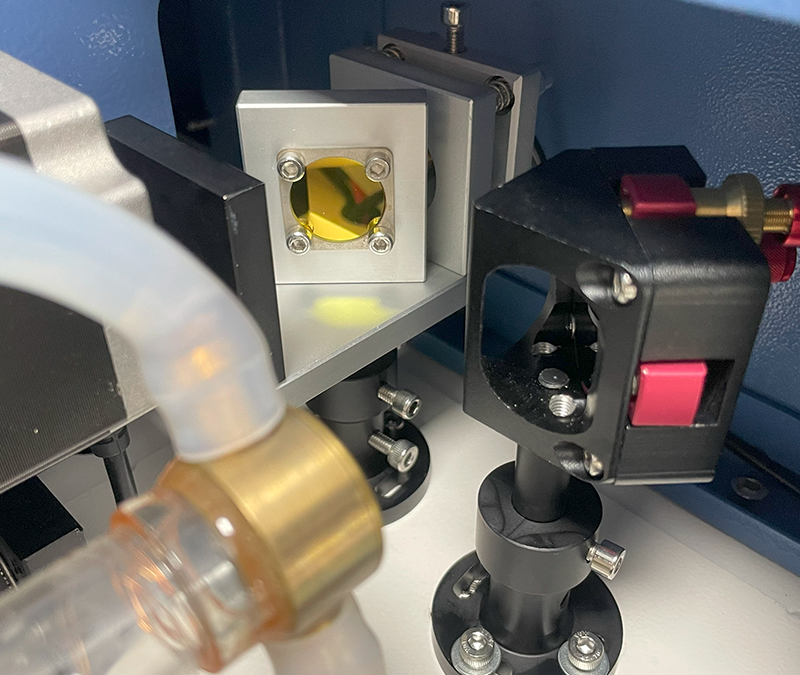

For those interested in exploring these business opportunities, the MYounglaser CO2 laser machines provide unmatched precision, efficiency, and reliability. Features such as Japan Shinano motors and self-cleaning guide rails ensure that the machines deliver high-quality cuts with every use. Whether you’re cutting intricate jewelry or large-scale architectural models, MYounglaser machines guarantee top-notch results.

Ready to start your acrylic laser cutting business? Choose MYounglaser and elevate your business with our advanced laser cutting solutions!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.