What Makes Acrylic an Ideal Material for CO2 Laser Cutting?

INDUSTRIAL NEWS

What Makes Acrylic an Ideal Material for CO2 Laser Cutting?

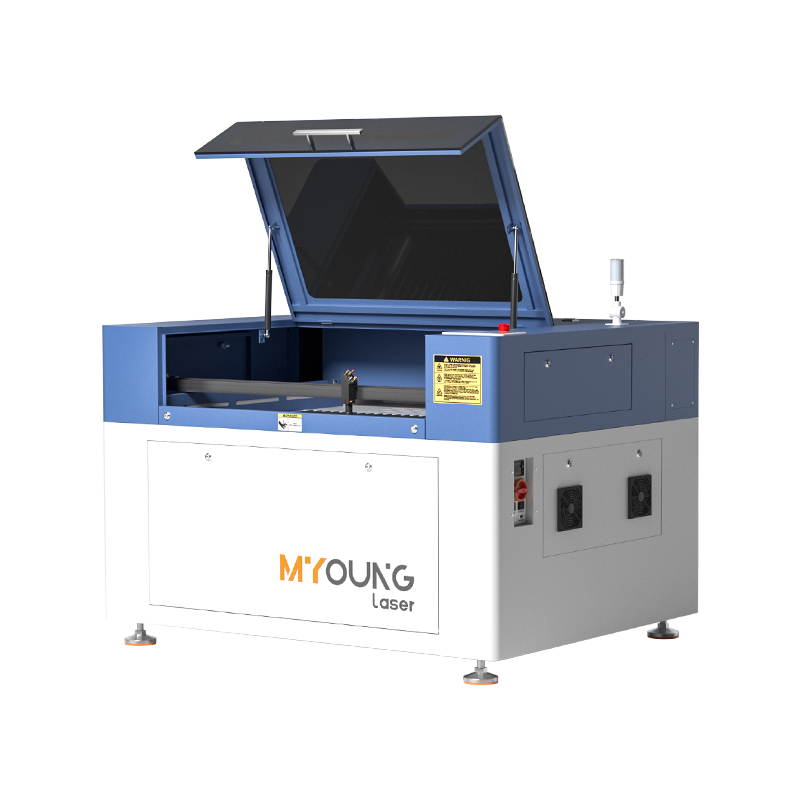

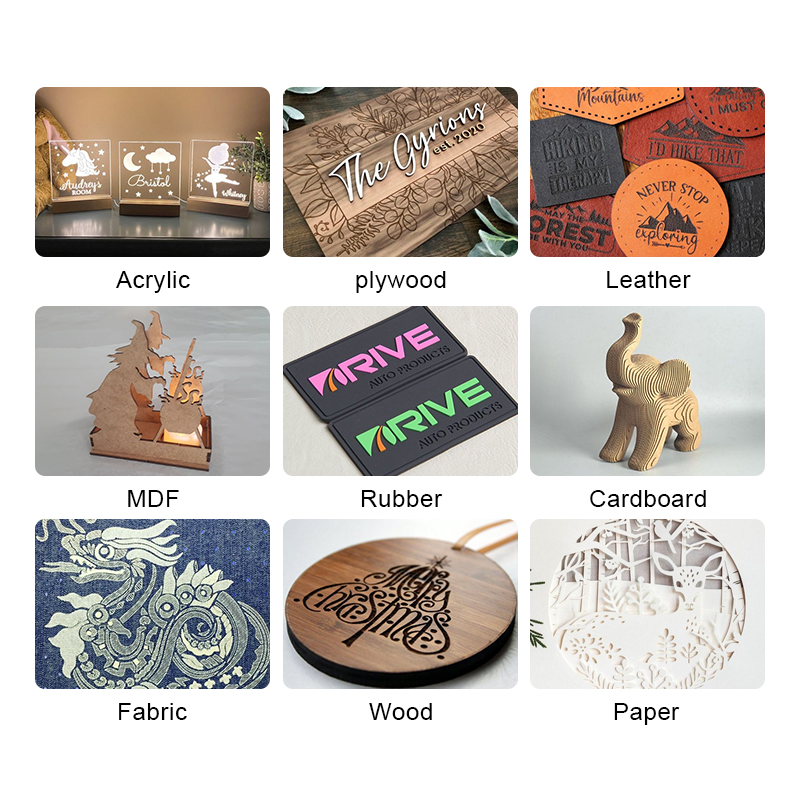

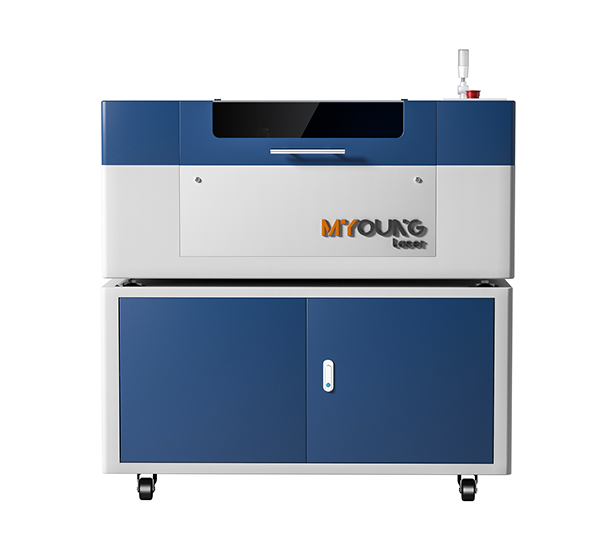

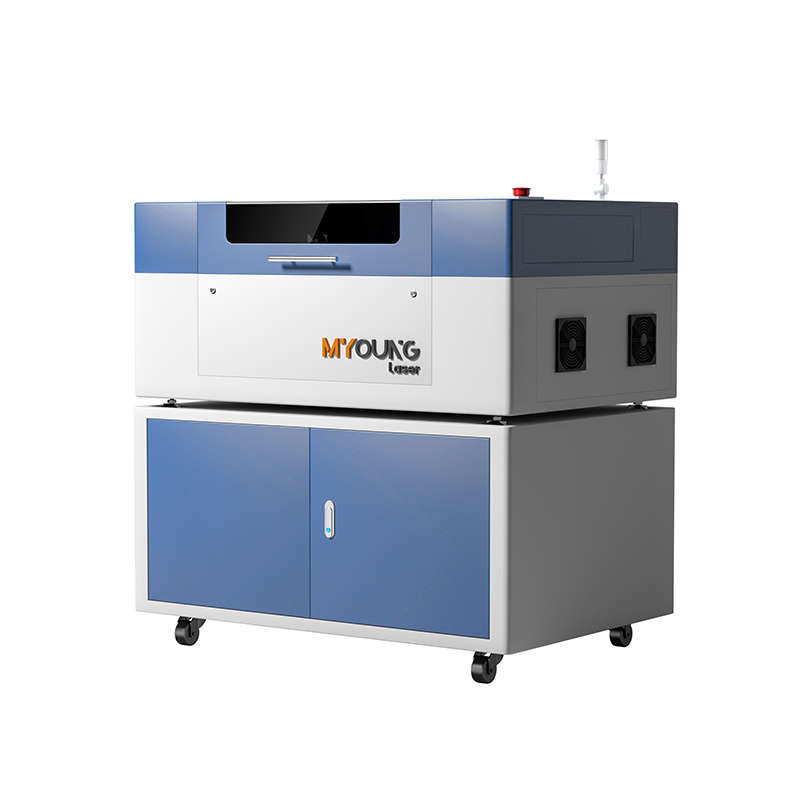

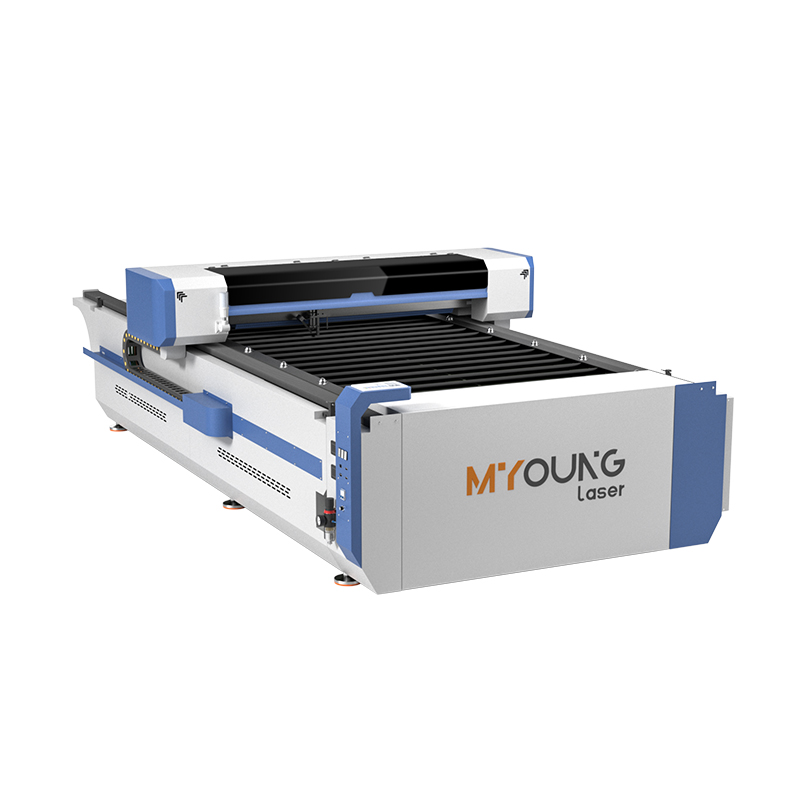

Acrylic is a popular material widely used in various industries, from signage and displays to home décor and manufacturing, and it is especially suitable for CO2 laser cutting. In this article, we’ll explore the key reasons why acrylic stands out as an excellent material for laser cutting and engraving, particularly with CO2 laser machines from MYounglaser. Whether you’re in the market for acrylic CO2 laser cutting machines or working with CO2 laser machine suppliers, this guide will help you understand the benefits of choosing acrylic.

1. Acrylic’s Laser-Friendly Properties

Acrylic is particularly responsive to laser technology, making it an ideal candidate for CO2 laser machines. When a laser beam interacts with acrylic, it cuts through the material cleanly and efficiently. This is largely due to the fact that acrylic absorbs the laser’s energy very effectively.

CO2 laser machines emit infrared light, which is perfectly suited to melt and vaporize acrylic, allowing precise cuts without damaging the surrounding material. Whether you’re working with MYounglaser equipment or machines from other CO2 laser machine suppliers, acrylic’s responsiveness ensures smooth, polished edges.

2. Excellent Edge Finish

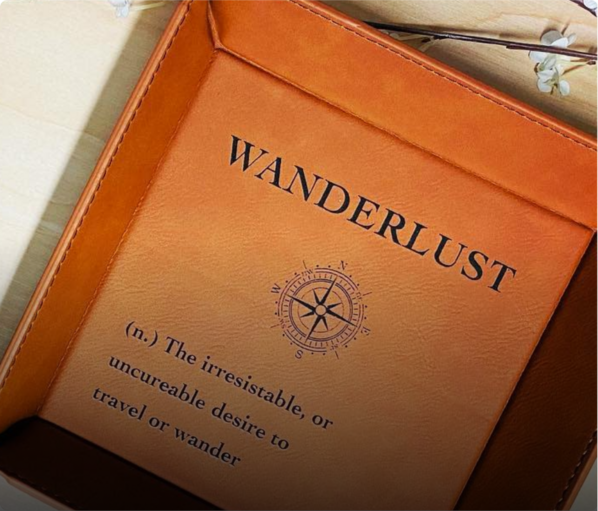

One of the standout benefits of cutting acrylic with a CO2 laser machine is the high-quality edge finish. Unlike other materials that may require post-processing to remove rough or burned edges, acrylic maintains a clean, polished edge directly after the cut. This can significantly reduce production time and costs, making it a favorite among manufacturers.

For instance, MYounglaser machines can deliver crisp, clear, and aesthetically pleasing edges on both transparent and colored acrylic sheets, which is especially beneficial for industries like advertising and home décor.

3. Versatility in Design and Thickness

Acrylic is available in a range of colors, finishes, and thicknesses, making it extremely versatile. Whether you are cutting thin sheets for intricate designs or thicker ones for structural purposes, acrylic CO2 laser cutting machines can handle the task with precision.

CO2 lasers can easily cut acrylic sheets of various thicknesses. With the advanced capabilities of MYounglaser machines, you can process acrylic up to 40mm thick with smooth edges and precise detailing. This makes it ideal for a wide range of applications from fine decorative pieces to large, functional components.

4. Durability and Longevity

Acrylic is known for its durability, resistance to impact, and ability to withstand environmental factors like UV light and weather. Once laser-cut, acrylic retains these properties, ensuring that the finished product is not only precise but also long-lasting. This durability makes acrylic a top choice in the signage industry, where weather resistance is critical.

5. High Transparency and Optical Clarity

Clear acrylic offers high optical clarity, which is unmatched by many other materials. This makes it particularly suitable for displays, windows, and even lenses. A CO2 laser machine can cut clear acrylic without clouding or distorting the material, allowing for the creation of visually stunning products.

With MYounglaser’s CO2 machines, you can create custom pieces with unparalleled clarity, whether for commercial displays or art installations.

6. Cost-Effective and Efficient

Acrylic is not only affordable compared to many other materials but also allows for efficient use when paired with CO2 laser machines. The precise nature of laser cutting ensures minimal material wastage, and the ability to produce large quantities of identical parts quickly makes it highly efficient for production.

7. Environmentally Friendly

Unlike many other plastics, acrylic is more eco-friendly as it can be recycled. The waste produced during the cutting process can be repurposed, reducing the environmental impact of large-scale manufacturing operations.

Acrylic’s unique properties – including its laser compatibility, excellent edge finish, versatility, and durability – make it an ideal material for use with CO2 laser machines. For anyone in need of CO2 laser machine suppliers or looking for advanced acrylic CO2 laser cutting machines, MYounglaser offers a range of solutions designed to maximize cutting efficiency and quality. Whether you are working on small intricate designs or large-scale industrial projects, acrylic is a material that ensures precision, beauty, and cost-effectiveness.