Understanding CO2 Laser Machines for Acrylic Applications

INDUSTRIAL NEWS

Understanding CO2 Laser Machines: Acrylic Applications

CO2 laser machines have revolutionized a wide range of industries since their inception in the 1960s. Initially developed for industrial manufacturing, these machines are now widely used in fields such as signage, automotive, electronics, and even in small businesses and personal projects. The technology works by using a gas mixture primarily consisting of carbon dioxide (CO2), which is electrically stimulated to produce a focused laser beam. This laser beam can cut or engrave a variety of materials, including metals, plastics, and—most importantly for this discussion—acrylic.

The Evolution and Role of CO2 Laser Machines

CO2 laser technology has come a long way since its inception. Initially, laser systems were large, costly, and limited to heavy-duty industrial applications. However, advances in technology have made CO2 laser machines more accessible, affordable, and versatile. Today, businesses of all sizes, including startups and small workshops, can take advantage of CO2 laser cutting machines for precise cutting and engraving.

These machines are incredibly efficient at cutting non-metallic materials, with acrylic being a standout example. Acrylic, a clear, durable plastic, is used in a wide variety of applications such as signage, display cases, decorative items, and even industrial prototypes. The clean and precise cuts produced by CO2 lasers make acrylic an ideal material for high-end, detailed projects.

Why Acrylic?

Acrylic, known for its durability, flexibility, and aesthetic appeal, is highly compatible with CO2 laser cutting machines. It is a thermoplastic material that vaporizes when exposed to the laser beam, producing smooth, flame-polished edges without the need for further finishing. This makes acrylic one of the most popular materials for laser cutting applications across industries.

The combination of acrylic’s properties and the precision of CO2 laser technology enables the production of intricate designs and high-quality finished products. The applications are almost endless, from crafting signage and displays to creating complex decorative elements and even functional prototypes.

Key Applications of Acrylic CO2 Laser Cutting Machines

Signage and Displays: One of the most common uses of acrylic is in the production of professional, polished signage. The precision of CO2 laser cutting allows for intricate designs that stand out in any commercial setting.

Decorative and Artistic Projects: Artists and designers frequently use acrylic in laser cutting machines to create custom decorative pieces, jewelry, and artwork. The material’s versatility enables a wide range of creative possibilities.

Prototypes and Engineering Models: Acrylic’s durability and clarity make it ideal for producing prototypes and models, especially in the engineering and architecture industries.

MYounglaser CO2 Laser Machines for Acrylic

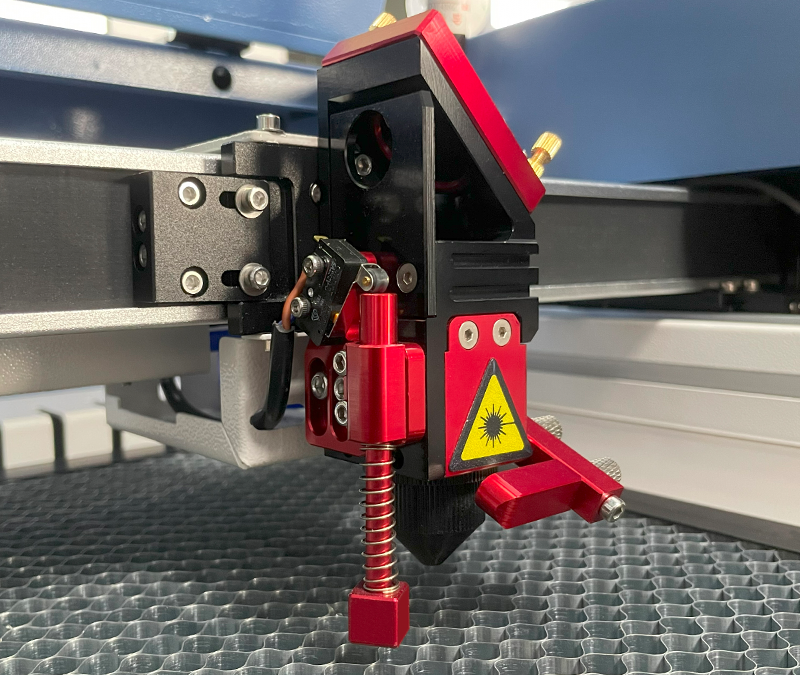

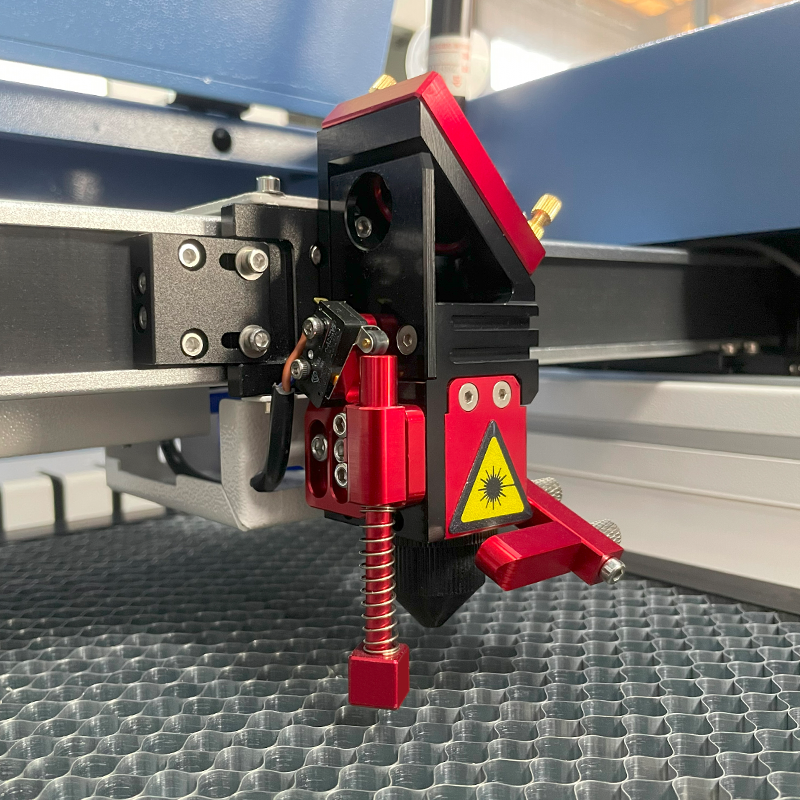

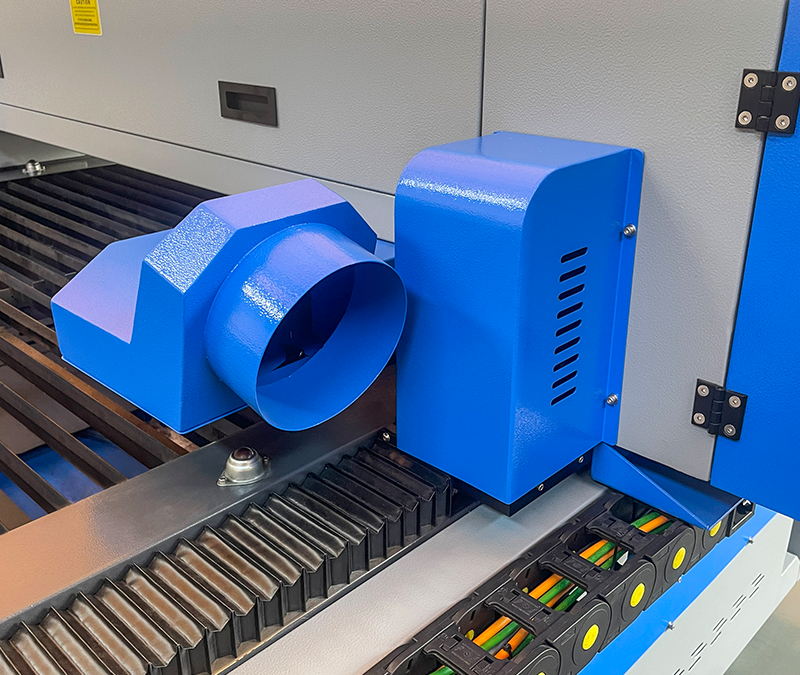

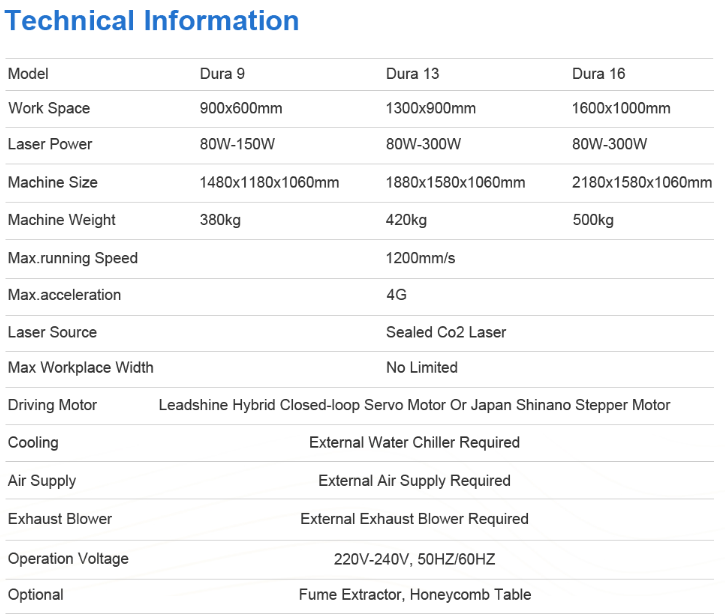

MYounglaser offers a range of CO2 laser machines designed specifically for cutting and engraving acrylic. Our machines, including the Dura series, feature cutting-edge technology to ensure precision, speed, and reliability.

Here are some of the key features of the Dura series that make it ideal for acrylic applications:

- Linear Module Guide Rails: Ensure smooth operation with self-cleaning capabilities, making it easier to maintain accuracy and speed.

- Japan Shinano Motor and Driver: High torque, high precision, and high performance, ensuring consistent quality in every project.

- Premium Components: Our machines are equipped with top-of-the-line control systems, laser tubes, and water chillers, guaranteeing optimal performance even in demanding conditions.

- Durable Construction: Built in compliance with industry safety standards, our machines are designed to provide long-term, reliable service.

Acrylic is one of the best materials for CO2 laser cutting due to its versatility, durability, and the ability to achieve precise, polished results with minimal post-processing. If you’re considering starting or expanding your acrylic cutting projects, MYounglaser offers advanced solutions that combine cutting-edge technology with user-friendly design, ensuring you can create high-quality products with ease. Explore our Dura series and experience the future of acrylic laser cutting today.