INDUSTRIAL NEWS

How to Avoid Cracks and Fractures in Acrylic Laser Cutting

Cutting acrylic with a CO2 laser machine is popular for achieving clean, precise edges, but without the right techniques, issues like cracking and fracturing can arise. Here’s a guide to help you prevent these problems and get the best results in your acrylic laser cutting projects.

1. Choose the Right Acrylic Type

- Cast Acrylic: Cast acrylic is often preferred for laser cutting because it melts cleanly, resulting in smooth edges. It is less likely to crack or fracture than extruded acrylic, which can be more brittle and challenging to work with under high temperatures.

- Thickness Matters: Thicker acrylic sheets may require multiple passes or slower cutting speeds to avoid stress buildup that could lead to cracks. Selecting the correct thickness for your project can significantly reduce the risk of damage.

2. Optimize Laser Settings

- Power and Speed: Adjust the laser power and speed based on the thickness and type of acrylic. For a clean cut without fractures, start with lower power settings and moderate speed. High power can generate excessive heat, causing thermal stress and cracks along the cutting path.

- Focus and Frequency: Correct focusing is essential to avoid uneven cuts. Additionally, setting the laser frequency appropriately for acrylic helps achieve smoother cuts without causing micro-cracks along the edges.

3. Use Air Assist Effectively

- Prevent Heat Buildup: An air assist system helps remove excess heat and debris from the cutting area, reducing the chances of cracks. Adjusting the air pressure correctly ensures the laser maintains a cool cutting environment without introducing additional stresses.

- Protects Edges: Air assist also prevents melting or warping along the edges, resulting in a polished cut. Properly directed airflow minimizes the likelihood of fractures.

4. Avoid Excessive Overlap in Design

- Plan Your Cuts: Overlapping cuts or revisiting the same cutting line multiple times can create weak points in the acrylic, making it prone to cracking. Plan your design to avoid excessive cuts in the same area.

- Smooth Paths: Sharp angles or intricate details may lead to fractures, especially if the laser pauses or lingers. Ensure your design has smooth paths to allow continuous laser movement without causing stress points.

5. Preheat or Gradually Adjust Laser Settings for Thick Acrylic

- Preheating Technique: For thicker acrylic sheets, some professionals preheat the acrylic slightly before cutting to help it better withstand the laser heat without cracking.

- Gradual Power Increase: Start with a lower power setting and gradually increase it to achieve the desired depth. This gradual approach helps avoid sudden temperature changes that might otherwise fracture the material.

6. Prevent Post-Cutting Stress

- Avoid Quick Temperature Changes: After cutting, let the acrylic cool down gradually to prevent cracks from sudden temperature shifts. Avoid handling the cut pieces immediately, especially if they’re thick.

- Polishing and Finishing: Use appropriate polishing techniques, such as flame polishing, to smoothen edges without introducing stress. However, be careful with heat levels during polishing to avoid further damage.

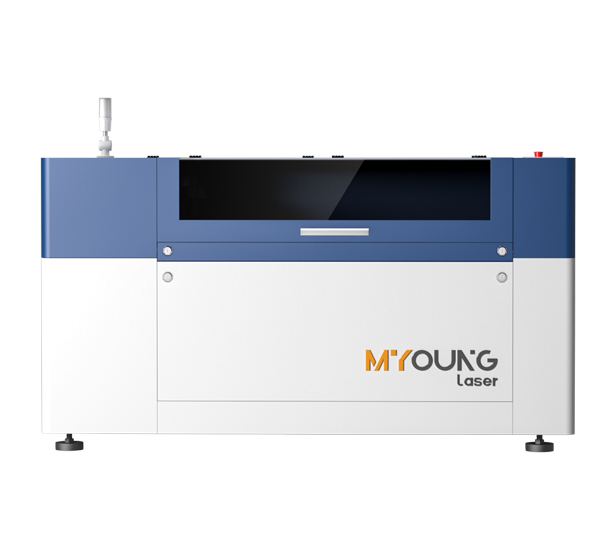

Cracks and fractures in acrylic laser cutting can often be avoided by selecting the right materials, using optimized machine settings, and ensuring gradual temperature changes. MYounglaser’s CO2 laser machines are designed to handle acrylic with precision, offering reliable performance and smooth cuts that help reduce the risk of material damage.

Ready to start your acrylic laser cutting journey? Check out MYounglaser’s range of CO2 laser machines designed for acrylic and other materials. Get the best results with a machine built for precision and durability!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.