Top 10 Laser-Cut Acrylic Artworks You Must See

INDUSTRIAL NEWS

Top 10 Laser-Cut Acrylic Artworks You Must See

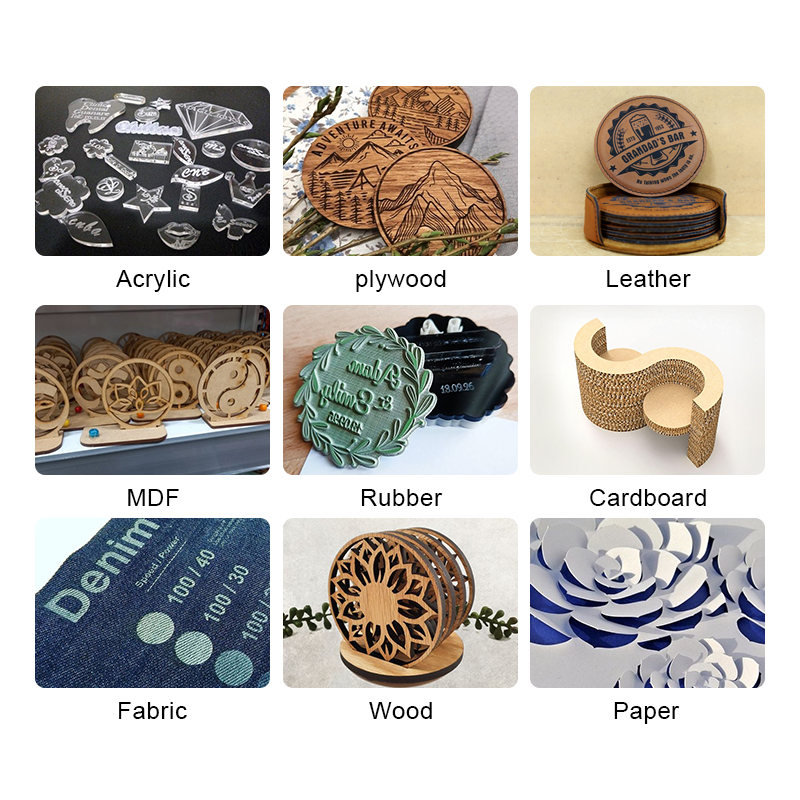

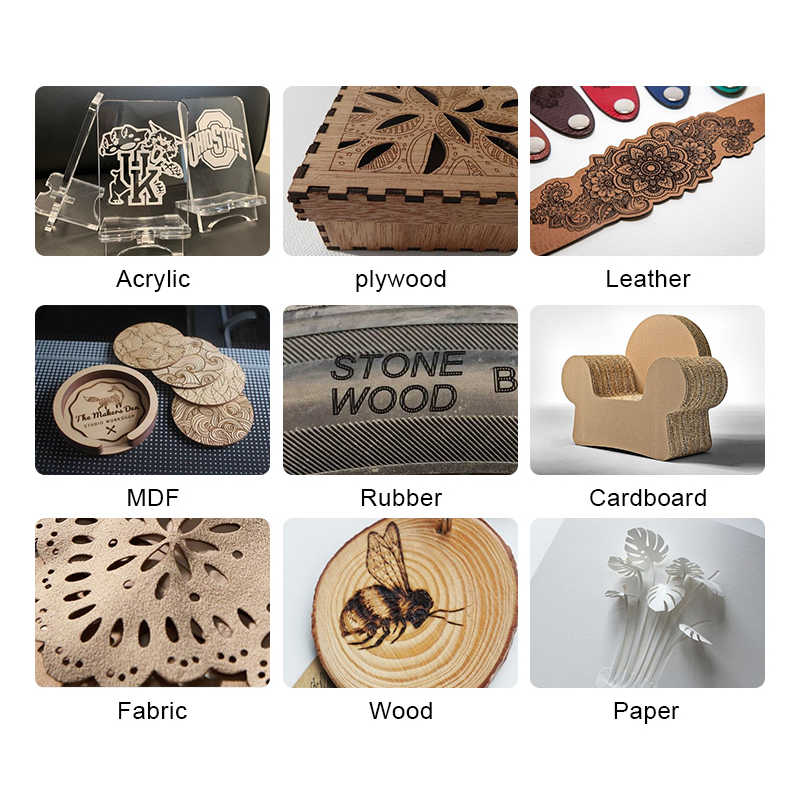

Acrylic has become a favorite material for artists and designers thanks to its versatility, clarity, and ease of manipulation. When combined with the precision of CO2 laser machines, acrylic can be transformed into intricate, breathtaking pieces of art. From sculptures to wall decor, laser cutting has opened new avenues for creativity. In this article, we’ll explore the top 10 laser-cut acrylic artworks that showcase the incredible potential of this medium.

1. Geometric Wall Art

Laser-cut acrylic’s ability to create sharp, precise edges makes it perfect for geometric designs. These modern, minimalist pieces use layered acrylic to create intricate 3D designs that play with light and shadow.

Why It’s Stunning: The combination of translucent acrylic layers creates a sense of depth and dimensionality, making each piece appear to come to life.

Laser Machine Used: MYounglaser’s CO2 laser machines are ideal for cutting and engraving these geometric shapes with exceptional precision.

2. Personalized Family Name Signs

Acrylic laser cutting allows for the creation of personalized home décor, such as custom family name signs. These pieces often feature elegant, flowing script combined with intricate decorative elements.

Why It’s Stunning: The clear acrylic allows for the design to appear to float against any background, giving it a modern yet timeless aesthetic.

Laser Machine Used: CO2 laser machines are perfect for engraving fine details and cutting out large shapes like family names.

3. Customizable Keychains

Laser-cut acrylic is an excellent choice for creating customized keychains. Artists and entrepreneurs can produce personalized gifts, logos, and designs, all with fine details.

Why It’s Stunning: The transparency of the acrylic allows light to pass through, adding an eye-catching shine. The fine detail achievable with laser cutting makes these small accessories stand out.

Laser Machine Used: MYounglaser machines offer precision cutting to achieve sharp and clean edges, even on small keychains.

4. 3D Acrylic Sculptures

Acrylic’s versatility shines when it comes to 3D sculptures. Artists use laser cutting to create intricate designs that are then stacked, layered, or arranged to create a stunning three-dimensional effect.

Why It’s Stunning: The ability to layer pieces with different thicknesses of acrylic allows for an immersive, dimensional experience that is both delicate and bold.

Laser Machine Used: MYounglaser’s Dura Series can handle large-scale projects with precise cutting, making it perfect for complex sculptures.

5. Acrylic Photo Frames

Laser-cut acrylic photo frames can be customized with intricate patterns, engraving, or even personalized text. They provide a sleek, modern look to photographs while keeping them protected.

Why It’s Stunning: Acrylic frames allow for a minimalist, elegant look while making the photo stand out due to its crystal-clear transparency.

Laser Machine Used: CO2 laser machines are perfect for creating personalized edges, patterns, and engraving on photo frames with clarity and accuracy.

6. Acrylic Clocks

Laser-cut acrylic clocks are modern, functional art pieces. These clocks can be customized with designs that fit personal tastes or specific spaces.

Why It’s Stunning: The ability to cut intricate numbers and designs, combined with the precision required for clock mechanics, makes laser-cut acrylic clocks a true testament to craftsmanship.

Laser Machine Used: MYounglaser CO2 laser machines are ideal for making precise cuts and ensuring accurate measurements for clock face components.

7. Layered Acrylic Light Fixtures

One of the most striking uses of laser-cut acrylic is in creating custom light fixtures. Layered acrylic pieces, cut into various shapes, are illuminated to produce beautiful, diffused lighting effects.

Why It’s Stunning: The laser cutting of acrylic enables artists to achieve unique shapes and patterns that create stunning visual effects when illuminated.

Laser Machine Used: MYounglaser CO2 laser cutters are designed to cut through thicker acrylic pieces, making them ideal for large-scale light fixture designs.

8. Intricate Laser-Cut Jewelry

Laser-cut acrylic is an innovative material for creating jewelry pieces that stand out. Whether it’s necklaces, earrings, or rings, laser cutting offers high precision, making complex patterns and designs possible.

Why It’s Stunning: The clean cuts and high-detail engraving provide a unique, artistic look that other materials may not be able to achieve.

Laser Machine Used: MYounglaser machines are perfect for cutting out detailed designs in acrylic, offering accuracy needed for jewelry production.

9. Custom Awards and Trophies

Laser-cut acrylic is commonly used for creating custom awards and trophies. Artists can design intricate and personalized shapes and engravings, making each award one of a kind.

Why It’s Stunning: The glossy finish of acrylic combined with precise engraving gives these awards a polished, professional appearance.

Laser Machine Used: CO2 laser machines from MYounglaser are perfect for engraving text and cutting out complex shapes, providing a high-quality finish.

10. Acrylic Planters and Terrariums

Laser-cut acrylic is also used to create stylish planters and terrariums, combining functionality with aesthetics. These can be customized with unique shapes and detailed designs, making them stand out as decorative pieces.

Why It’s Stunning: The transparent nature of acrylic enhances the visual appeal of plants while adding a modern touch to any space.

Laser Machine Used: MYounglaser offers precision cutting for smooth edges and accurate engraving on both thin and thick acrylic sheets.

Why Choose MYounglaser for Your Acrylic Laser Cutting Needs?

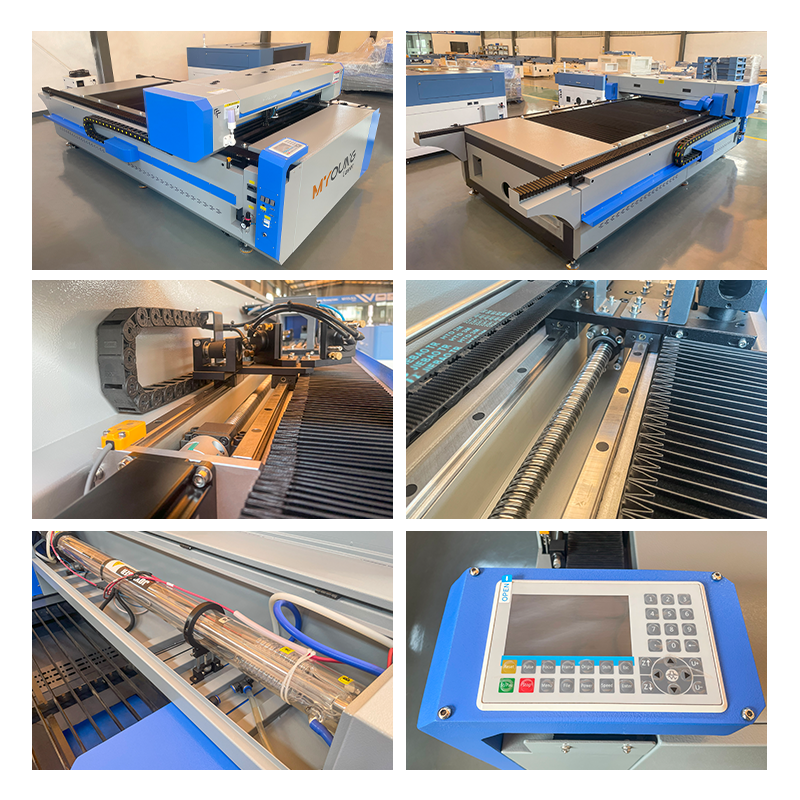

MYounglaser stands out as a leading CO2 laser machine supplier with a reputation for precision, reliability, and versatility. Whether you’re creating intricate acrylic art, signage, or custom products, MYounglaser’s machines offer the high-quality cutting and engraving required for flawless results.

- High Precision: MYounglaser CO2 machines are equipped with advanced technology to ensure accuracy and detail, making them perfect for acrylic projects.

- Durability: Built for long-lasting use, MYounglaser machines ensure reliability in both small and large-scale productions.

- Support and Service: MYounglaser offers exceptional customer support, ensuring your machine works flawlessly throughout its lifespan.

Laser-cut acrylic artworks offer a beautiful blend of creativity and precision, showcasing the impressive potential of CO2 laser machines. Whether you’re an artist, a small business owner, or a designer, incorporating MYounglaser CO2 laser machines into your workflow will elevate your projects and allow you to create stunning, high-quality acrylic designs. Explore the possibilities of laser cutting and start bringing your acrylic art to life today!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.