Affordable CO2 Laser Machines for Woodworking

INDUSTRIAL NEWS

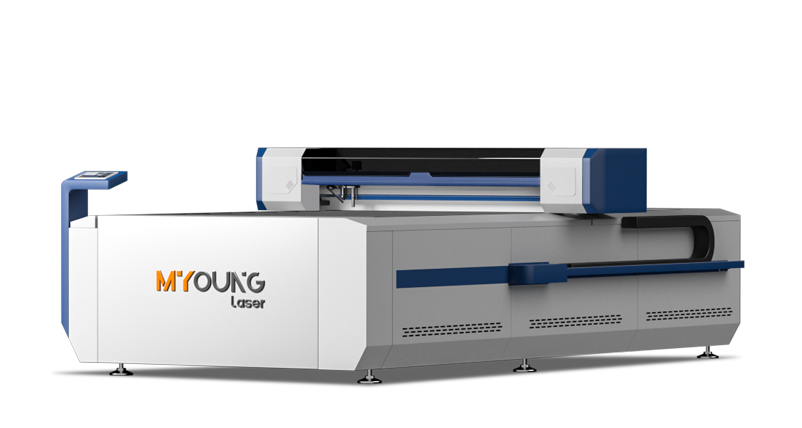

Our Budget Series CO2 laser machines are the perfect solution for woodworking enthusiasts and small-scale entrepreneurs looking to enhance their craft. These machines are designed with flexibility, affordability, and high performance in mind, making them ideal for personal projects and small businesses alike.

Why Choose the Budget Series for Woodworking?

- All-in-One Design: The Budget Series machines are designed for convenience. With an all-in-one setup, you can start working as soon as the machine is set up, saving you time and effort.

- High Engraving Speed: Achieve detailed and intricate designs quickly with engraving speeds of up to 1900mm/s. This speed allows you to complete projects faster, increasing your productivity.

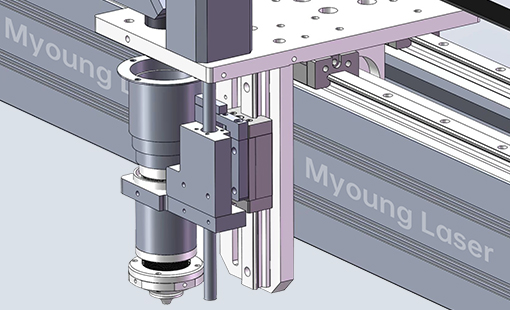

- Auto-Focus Laser Head: The auto-focus laser head ensures precision and accuracy in every cut and engraving, making it easier to work with different materials and thicknesses without constant adjustments.

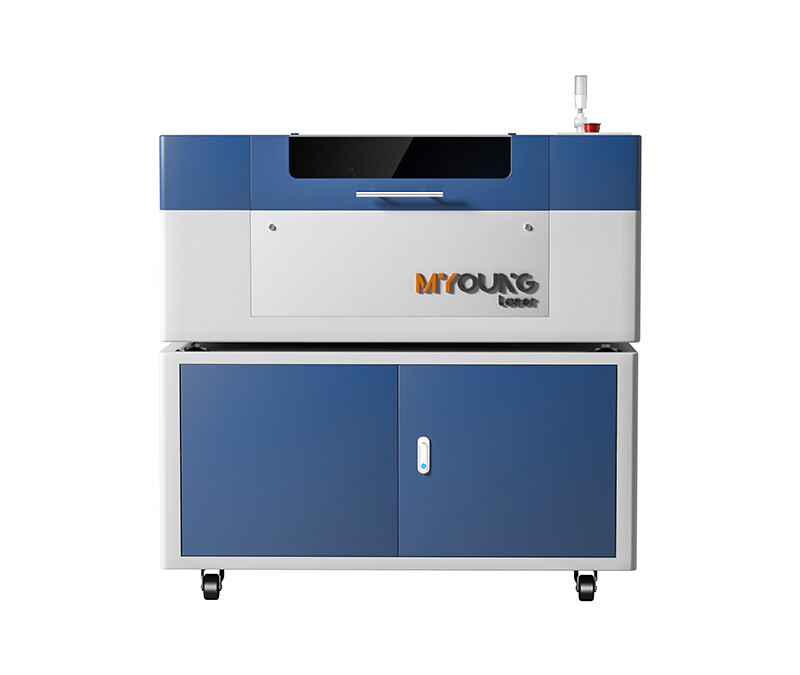

- Versatile Working Table: The up-and-down working table, equipped with a catchment drawer, offers flexibility for handling various sizes of materials, making it easier to switch between different projects.

Technical Specifications for the Budget Series

- Budget 5:

- Work Space: 500x300mm

- Laser Power: 40W-60W

- Machine Weight: 120kg

- Machine Size: 1000x680x430mm

- Budget 6:

- Work Space: 600x400mm

- Laser Power: 40W-60W

- Machine Weight: 140kg

- Machine Size: 1100x780x430mm

- Budget 7:

- Work Space: 700x500mm

- Laser Power: 40W-80W

- Machine Weight: 160kg

- Machine Size: 1200x880x530mm

All models come with built-in water pumps for cooling, air pumps, and exhaust blowers, ensuring that the machine operates efficiently and safely. Optional accessories like rotary devices, fume extractors, and honeycomb tables are also available to customize your machine according to your needs.

Why Our Budget Series Stands Out

Compared to other CO2 laser machines on the market, our Budget Series offers superior performance at an affordable price. The machines are lightweight yet powerful, making them easy to move and store while still providing the power needed for detailed woodworking tasks. Additionally, the integrated features and optional accessories make these machines versatile and adaptable to a wide range of projects, from simple engraving to complex cutting.

Ready to Elevate Your Woodworking Projects?

Our Budget Series CO2 laser machines are ready to help you take your woodworking projects to the next level. Whether you’re a hobbyist or an entrepreneur, these machines offer the perfect blend of performance, convenience, and affordability. Contact us today to learn more or to place your order!