Exploring the Market for CO2 Laser Machines in China: Trends and Opportunities

INDUSTRIAL NEWS

Exploring the Market for CO2 Laser Machines in China: Trends and Opportunities

The market for CO2 laser machines in China has expanded rapidly over recent years. This growth is driven by advances in technology, increased demand for precision in manufacturing, and the versatility of CO2 lasers in various applications. This article explores the current trends, opportunities, and the future outlook for CO2 laser machines in the Chinese market.

Key Trends in the CO2 Laser Machine Market

Technological Advancements Technological innovation is at the heart of the growing demand for CO2 laser machines. Recent developments have enhanced the precision, speed, and efficiency of these machines. Innovations such as automated control systems, AI integration, and improved laser sources have significantly increased the capabilities of CO2 laser machines.

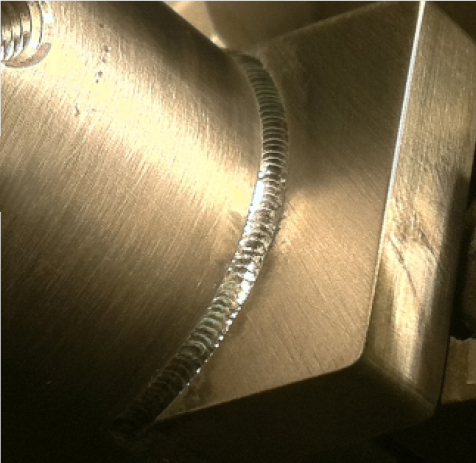

Increasing Demand for Precision Manufacturing Industries such as electronics, automotive, aerospace, and medical devices require high levels of precision in manufacturing. CO2 laser machines are ideal for tasks requiring intricate details and exact measurements, making them highly sought after in these sectors.

Expansion into New Applications Beyond traditional uses in cutting and engraving, CO2 laser machines are finding new applications in areas like 3D printing, material processing, and surface treatment. This diversification is expanding the market and creating new opportunities for manufacturers and users alike.

Focus on Sustainability There is a growing emphasis on sustainability in manufacturing processes. CO2 laser machines are considered environmentally friendly due to their energy efficiency and reduced waste production. Companies are increasingly adopting these machines to meet stringent environmental regulations and to enhance their green credentials.

Opportunities in the Chinese Market

Government Support and Investment The Chinese government has been actively supporting the development of advanced manufacturing technologies, including laser machining. Policies and funding initiatives aimed at fostering innovation and improving manufacturing capabilities are boosting the CO2 laser machine market.

Growing Manufacturing Sector China’s manufacturing sector continues to grow, driven by both domestic consumption and export demands. The need for advanced machinery to maintain competitive edge and production efficiency is leading to increased adoption of CO2 laser machines.

Export Potential Chinese manufacturers of CO2 laser machines are not only meeting domestic demand but also expanding their reach to international markets. Competitive pricing, coupled with high-quality products, makes Chinese CO2 laser machines attractive to global buyers.

The CO2 laser machine market in China is poised for continued growth and innovation. As technological advancements drive improvements in precision, efficiency, and application versatility, the market offers significant opportunities for both manufacturers and users. Government support, a robust manufacturing sector, and the potential for export expansion further enhance the attractiveness of this market.

For more information on CO2 lasers and their applications, you can visit the Wikipedia page on Laser Cutting.