Setting Up a Workshop for Acrylic CO2 Laser Cutting

INDUSTRIAL NEWS

Setting Up a Workshop for Acrylic CO2 Laser Cutting

CO2 laser machines have become increasingly popular for working with acrylic due to their ability to deliver precision and smooth finishes in cutting and engraving tasks. When setting up a workshop dedicated to acrylic CO2 laser cutting, there are several critical aspects to consider for an efficient, productive, and safe environment.

1. Selecting the Right CO2 Laser Machine

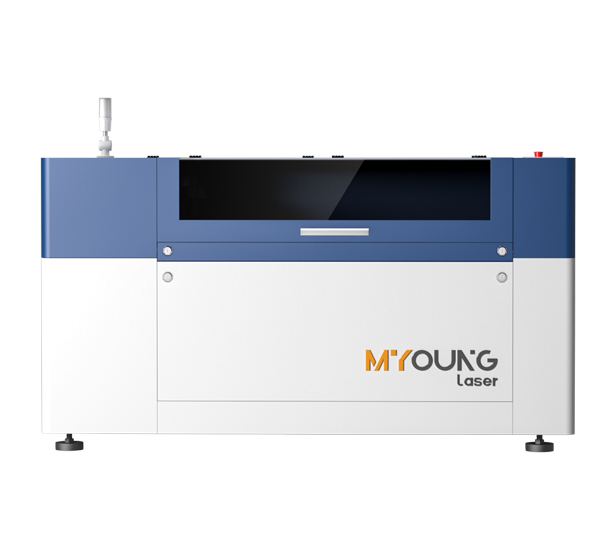

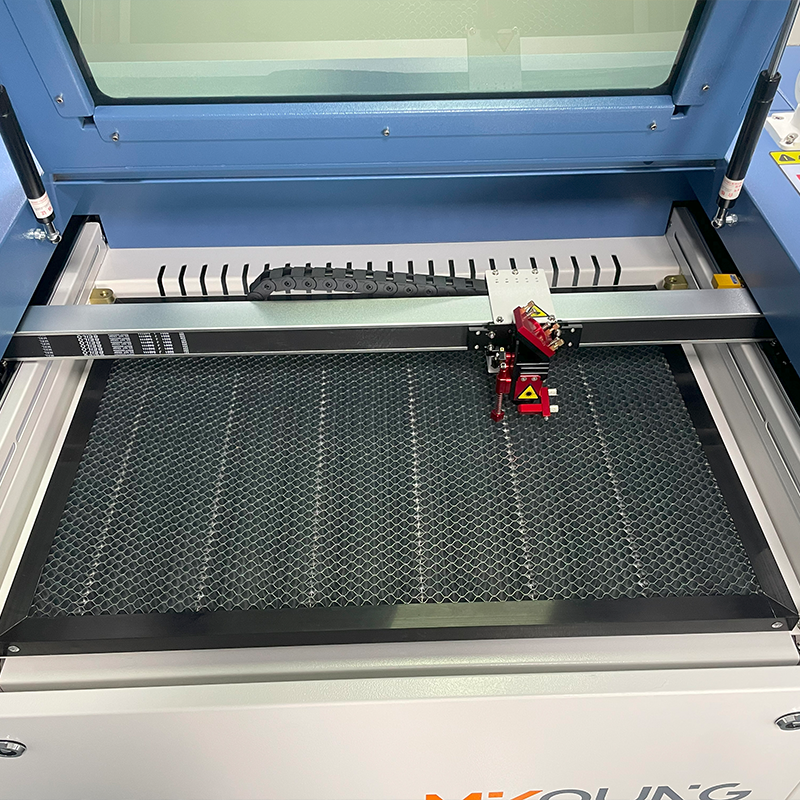

- Machine Type and Features: For an acrylic-based workshop, selecting a reliable CO2 laser machine with capabilities suited to the material is essential. MYounglaser offers high-quality options, such as its Dura series, which is known for precision and durability. When choosing a machine, consider factors like cutting area, power options, and compatibility with various acrylic thicknesses.

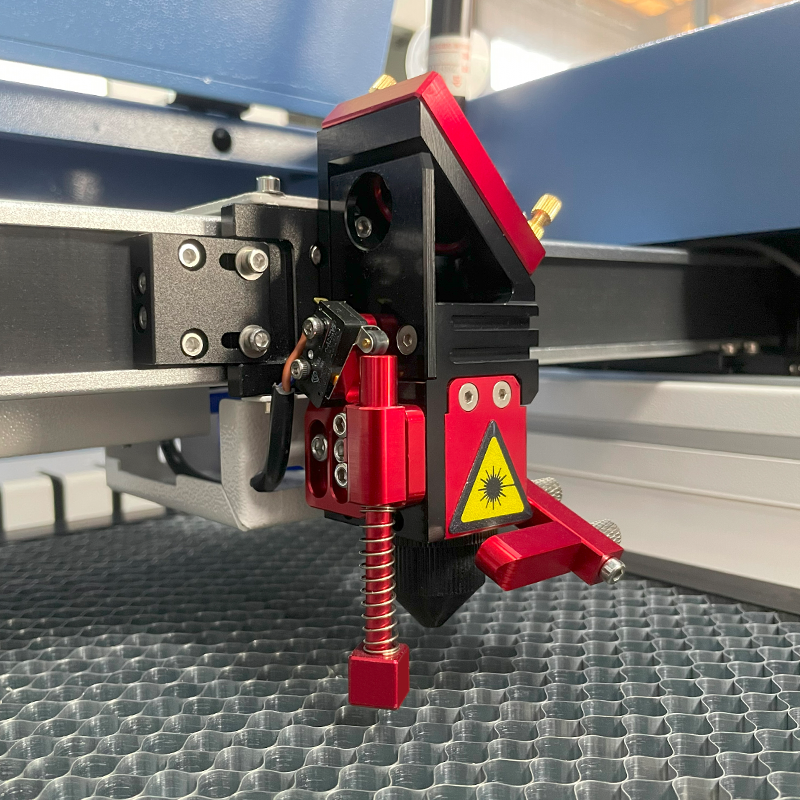

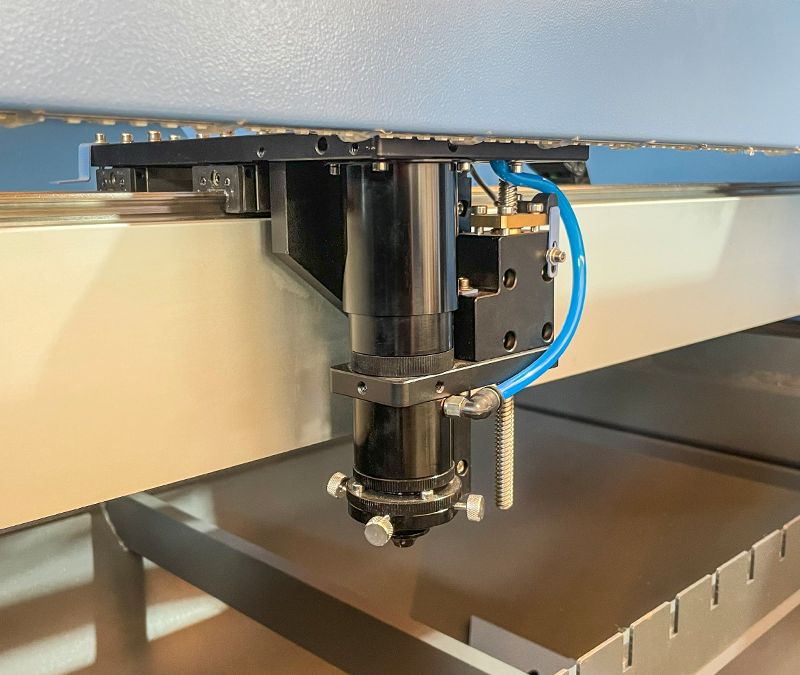

- Compatibility with Accessories: Machines compatible with additional accessories (e.g., air-assist nozzles and rotary attachments) allow for more versatility in acrylic cutting and engraving projects.

2. Ensuring Proper Ventilation and Fume Extraction

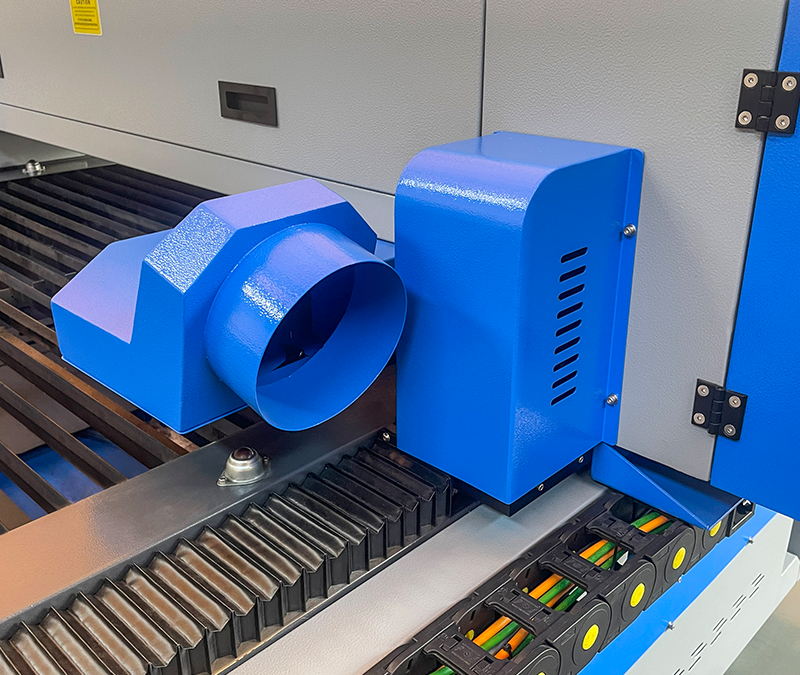

- Fume Extraction System: Laser cutting acrylic produces fumes and particles that can be harmful if inhaled. Installing a quality fume extractor ensures a safe working environment. Position your machine near an exterior wall for easier installation of exhaust systems.

- Ventilation: Beyond fume extraction, ensure that your workshop is well-ventilated. Regular airflow prevents the buildup of fumes and helps protect the machine and materials from overheating.

3. Setting Up a Stable Power Source

- Stable Voltage Supply: CO2 laser machines require a consistent power supply to maintain performance and safety. Many machines, including those from MYounglaser, operate at 220V-240V. Consider installing a voltage stabilizer if power fluctuations are common in your area.

- Dedicated Circuit: Setting up a dedicated electrical circuit for the laser machine can prevent interference from other devices and improve machine safety.

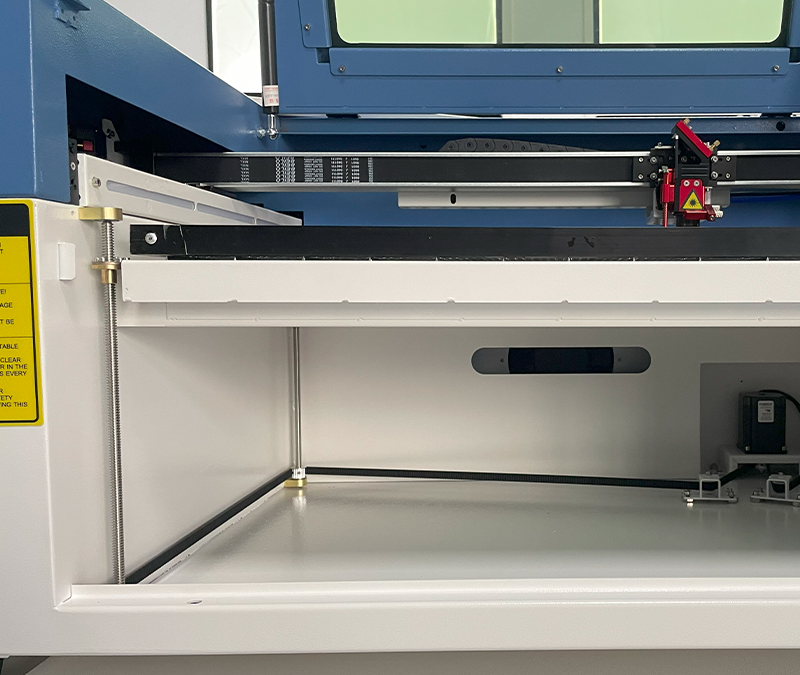

4. Organizing Workspaces and Material Storage

- Material Storage: Acrylic sheets and scraps should be stored in a designated area to keep your workspace organized and accessible. A storage rack or cabinet helps protect acrylic sheets from scratches, dust, and contaminants that could impact cutting quality.

- Cutting Surface Management: Invest in a honeycomb or knife-edge table, which can be integrated with CO2 laser machines to ensure precise cutting and prevent beam reflection damage to acrylic.

5. Safety Measures and Fire Prevention

- Fire Extinguishers: As laser cutting involves high temperatures, having a fire extinguisher specifically designed for electrical and chemical fires on hand is critical. Train all staff members on how to use it effectively.

- Eye Protection and Safety Protocols: While many CO2 lasers come with enclosed designs, eye protection is recommended, especially when inspecting or making adjustments to the machine.

6. Software and Design Preparation

- Design Software: Prepare to work with design software compatible with CO2 laser machines. Software like CorelDRAW, Adobe Illustrator, and LightBurn are commonly used for creating and adjusting cutting and engraving files.

- Machine Calibration: Calibrate your CO2 laser machine regularly for accurate and precise cuts. This includes checking focus settings, laser power, and machine speed based on the thickness and type of acrylic.

7. Maintenance and Regular Checks

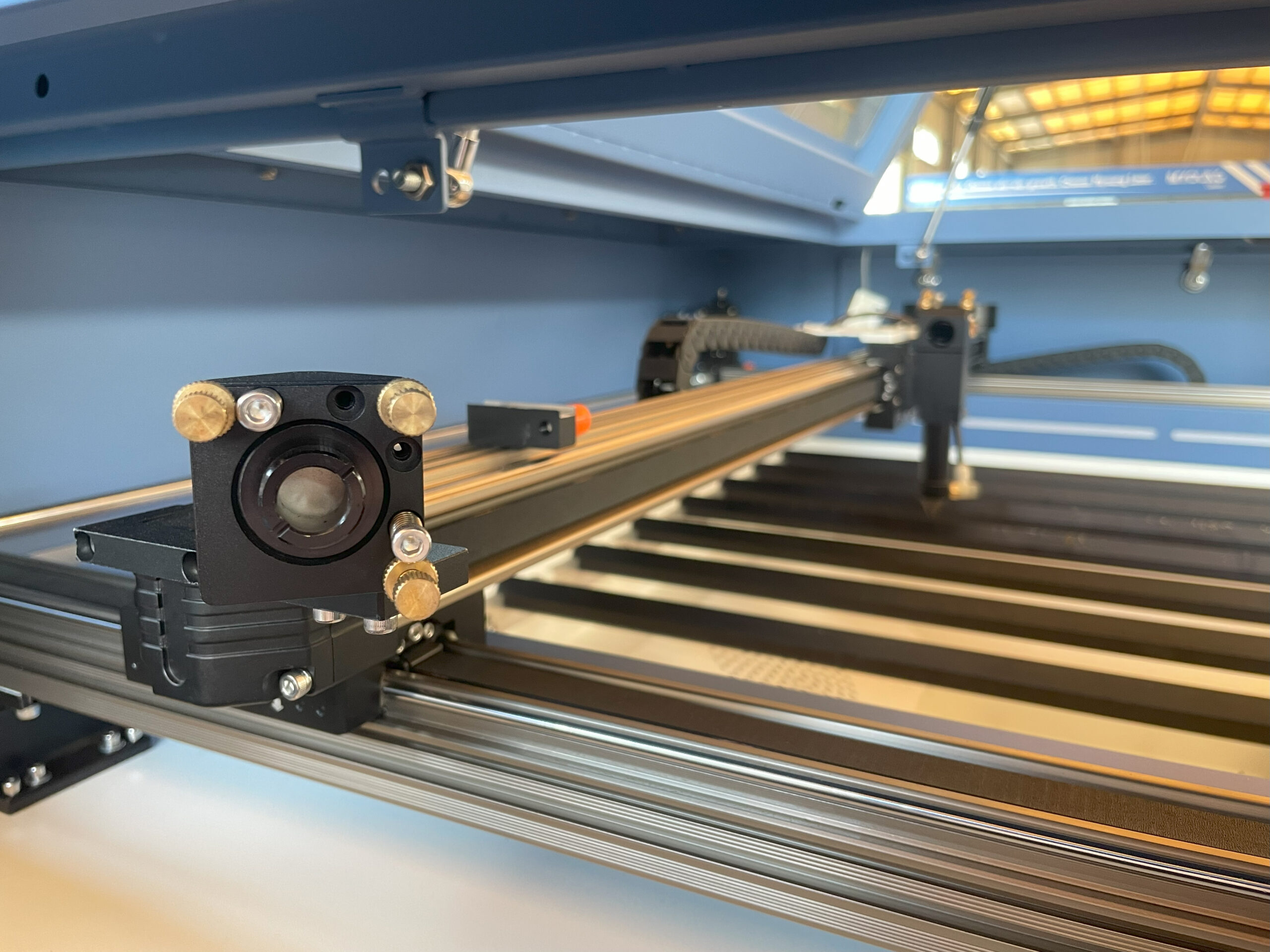

- Cleaning and Alignment: CO2 laser machines require regular cleaning of the lens, mirrors, and other components for optimal performance. Misalignment can lead to poor cut quality, so ensure components are aligned correctly.

- Scheduled Servicing: For a long-lasting machine, follow a maintenance schedule provided by the manufacturer, like MYounglaser, which includes periodic check-ups of essential components.

Setting up a dedicated acrylic CO2 laser cutting workshop requires careful consideration of the right equipment, layout, safety measures, and maintenance routines. A well-prepared workspace can make a significant difference in the quality of output, efficiency, and safety. Choosing a reliable and efficient CO2 laser machine, like the Dura series from MYounglaser, will help streamline your operations and support the production of high-quality acrylic products.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.