Acrylic vs. Other Materials: What’s Best for Laser Cutting?

INDUSTRIAL NEWS

Acrylic vs. Other Materials: What’s Best for Laser Cutting?

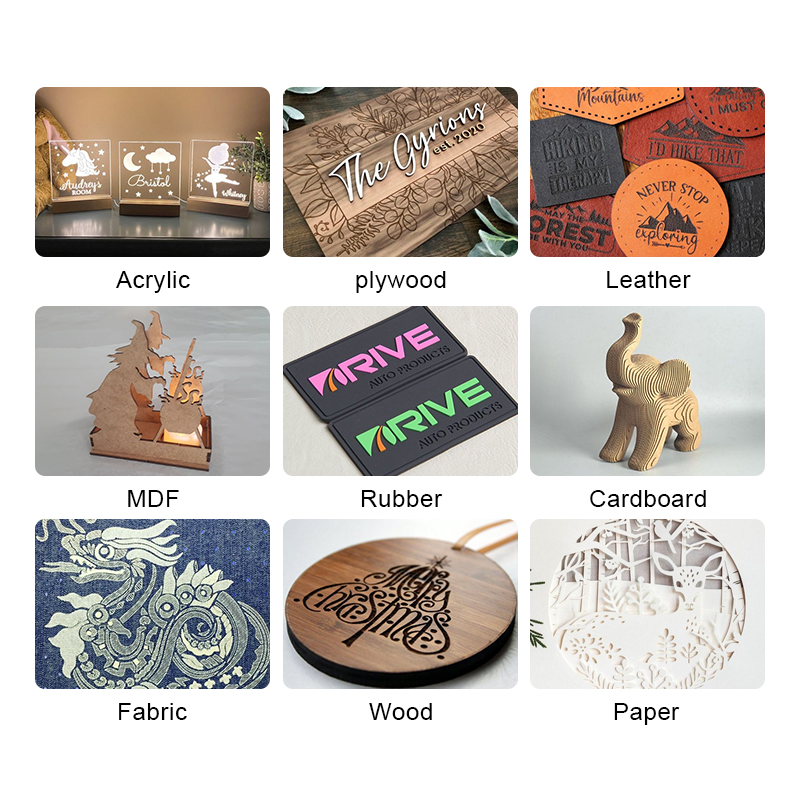

When it comes to laser cutting, choosing the right material is crucial for the quality and efficiency of your work. Among the wide range of materials available, acrylic has become a favorite for many laser cutting applications, but how does it stack up against other materials like wood, metal, and plastic? This article will compare acrylic with other popular materials used in laser cutting to help you decide which is best for your projects.

Why Choose Acrylic for Laser Cutting?

Acrylic is one of the most popular materials for laser cutting due to its clarity, versatility, and ease of use. Here’s why it stands out:

- Smooth, Polished Edges: When cut with a CO2 laser machine, acrylic produces a clean, polished edge without requiring post-processing. This makes it ideal for creating high-quality finishes in one step.

- Wide Variety of Colors and Thicknesses: Acrylic comes in multiple colors, thicknesses, and finishes, making it a versatile material for different applications like signage, display cases, jewelry, and artistic projects.

- Ease of Engraving: Acrylic can be easily engraved with a CO2 laser machine, resulting in sharp and detailed images or texts.

- Durability and Strength: Acrylic offers durability without the brittleness of glass, making it an ideal choice for both functional and decorative purposes.

How Acrylic Compares to Other Materials

Acrylic vs. Wood

Cutting and Engraving: Both materials are easy to cut and engrave with a CO2 laser machine, but the finish differs. Acrylic provides a polished edge, while wood requires sanding or other finishing treatments after cutting.

Appearance: Acrylic offers a glossy, transparent finish, whereas wood has a natural, rustic look. The choice depends on the aesthetic goals of your project.

Applications: Acrylic is used for more modern and industrial designs, while wood suits traditional and organic creations.

Acrylic vs. Metal

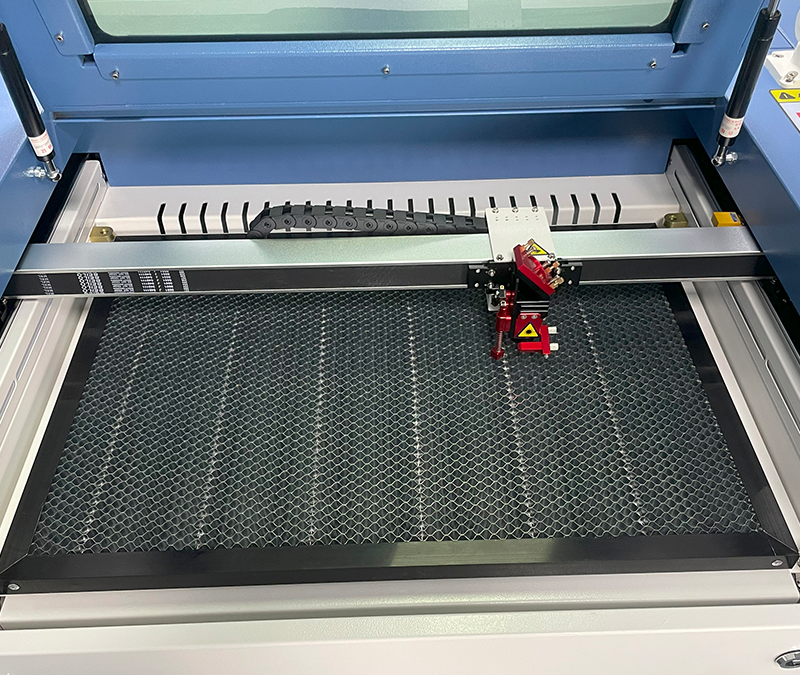

Laser Compatibility: Metal cutting requires higher-powered lasers (typically fiber or specialized metal CO2 lasers), making it more complex than acrylic cutting, which can be achieved with standard CO2 laser machines like the MYounglaser CO2 Laser Engraving series.

Cost: Cutting metals like aluminum or stainless steel generally involves higher operational costs due to the need for stronger laser systems. Acrylic cutting is more affordable, especially for those using a standard CO2 laser machine.

Applications: Acrylic is often used for signage, decorations, and lightweight structural components, while metal is better suited for industrial and mechanical parts.

Acrylic vs. Plastics (like PVC and Polycarbonate)

Safety: Acrylic is safer to cut with a CO2 laser machine compared to materials like PVC, which releases harmful gases when lasered.

Finish: While acrylic cuts smoothly, polycarbonate and other plastics tend to discolor or melt at the edges, requiring additional cleanup.

Durability: Acrylic is more rigid and less flexible compared to many plastics, but its hardness makes it ideal for items requiring structural integrity.

What Makes Acrylic a Popular Choice for CO2 Laser Machines?

Acrylic is not only versatile but also highly compatible with CO2 laser machines due to its responsiveness to the laser beam. When using machines like MYounglaser CO2 Laser Engraving models, acrylic delivers precise results, making it suitable for intricate designs and detailed work.

- Efficiency in Cutting and Engraving: CO2 laser machines are designed to handle acrylic with minimal power adjustments, which improves cutting speed and precision.

- User-Friendly Experience: Machines like those from MYounglaser, a leading CO2 laser machine manufacturer, offer user-friendly interfaces and settings specifically optimized for acrylic, ensuring consistency and professional-quality results.

Which Material is Best for Your Project?

Ultimately, the material you choose depends on your project’s requirements. Here’s a quick guide to help you decide:

- For High-Precision and Aesthetic Finishes: Acrylic is the top choice due to its polished edges and availability in various colors and thicknesses.

- For Organic and Rustic Designs: Wood is your go-to material, especially for engraving, but keep in mind the need for post-processing.

- For Heavy-Duty, Industrial Applications: Metal is better suited, but it requires a more powerful laser system.

- For Cost-Effective Projects: Acrylic stands out as a budget-friendly option for decorative items, signage, and functional components.

Why Acrylic and MYounglaser Machines are the Perfect Combination

Acrylic is one of the best materials for laser cutting, offering a balance of versatility, affordability, and ease of use. Whether you’re creating custom signage, display items, or artistic projects, MYounglaser’s CO2 laser machines provide the precision and performance you need for high-quality acrylic cutting and engraving. As a trusted CO2 laser machine manufacturer, MYounglaser offers cutting-edge technology designed to meet your production goals efficiently.

Ready to bring your acrylic projects to life? Contact us today to learn more about our range of CO2 laser machines and find the perfect model for your business!