How to Maintain Your Acrylic CO2 Laser Cutting Machine

INDUSTRIAL NEWS

How to Maintain Your Acrylic CO2 Laser Cutting Machine

Proper maintenance is crucial to ensure the longevity and optimal performance of your acrylic CO2 laser cutting machine. Regular care not only helps prevent technical issues but also maintains the precision and efficiency of the machine. In this guide, we’ll cover essential tips for maintaining your MYounglaser CO2 laser machines, helping you get the best results for acrylic cutting.

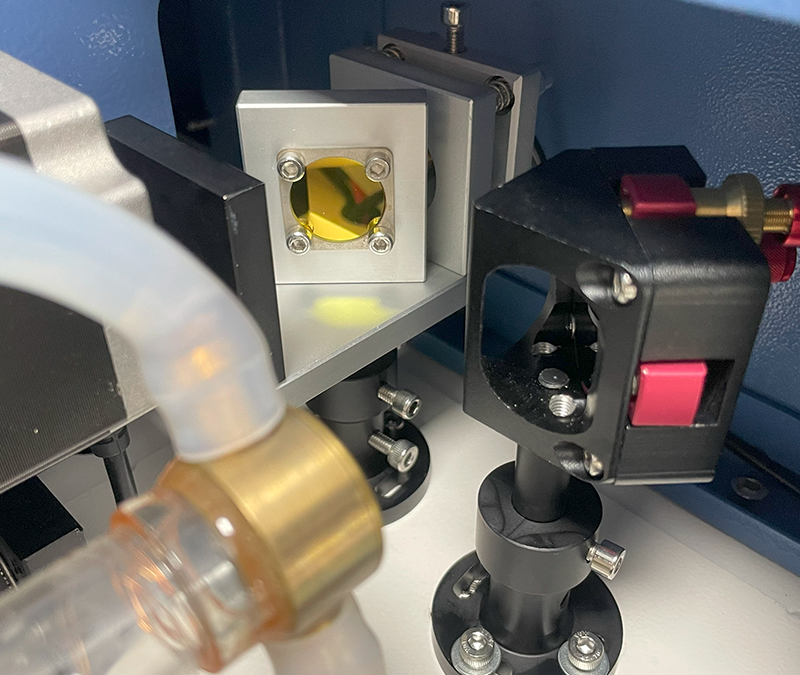

1. Clean the Optics Regularly

The optical components of a CO2 laser machine—mirrors and lenses—are critical to cutting precision. These components can accumulate dust, smoke, and residue from acrylic cutting, which can reduce the laser’s effectiveness and even damage the optics over time.

- Cleaning Frequency: Clean the lenses and mirrors after every 8–10 hours of cutting, especially after heavy cutting sessions.

- Cleaning Method: Use specialized lens wipes or isopropyl alcohol with a microfiber cloth to avoid scratches.

2. Check and Align the Laser Beam

A misaligned laser beam can lead to inefficient cutting or poor-quality results. Misalignment happens over time due to regular use, machine vibrations, or transportation.

- Beam Alignment: Check the beam alignment regularly and adjust if necessary. Use alignment tools or follow the manufacturer’s instructions for ensuring the beam hits the mirrors at the correct angles.

- Test Cuts: Regularly perform test cuts on scrap acrylic to verify the accuracy of the laser beam’s path.

3. Clean the Work Area and Ventilation System

During acrylic cutting, dust, fumes, and small acrylic particles can accumulate inside the machine and clog the ventilation system. Poor ventilation can affect the laser’s ability to cut smoothly and pose safety hazards.

Cleaning the Bed: Remove debris from the cutting bed after each use to prevent buildup.

Ventilation System: Check the exhaust fan and filtration systems weekly to ensure proper air circulation. Replace filters as needed.

4. Lubricate Mechanical Parts

Regular lubrication of the machine’s moving parts ensures smooth operation and prevents wear. Linear guides, bearings, and drive systems should be lubricated to maintain consistent movement during cutting.

Lubrication Schedule: Lubricate the moving parts every month or as recommended by the manufacturer.

Use Proper Lubricants: Only use machine-specific lubricants to avoid damage or malfunction.

5. Monitor Water Cooling System

Most acrylic CO2 laser cutting machines use a water chiller to cool the laser tube. Maintaining proper water flow and temperature is essential for preventing the laser tube from overheating and extending its lifespan.

Water Quality: Use distilled water to prevent mineral buildup and change the water every 3–6 months.

Temperature Check: Regularly check the water temperature and ensure it stays within the recommended range (usually 15°C–25°C).

6. Inspect and Replace the Laser Tube

The laser tube is the heart of any CO2 laser machine, and over time, it will wear out and lose power. Regularly monitor the power output and inspect the laser tube for any signs of wear.

Tube Lifespan: Most CO2 laser tubes have a lifespan of 1,000 to 3,000 hours of cutting.

Power Output: If the cutting performance declines or the laser struggles with thicker materials, it may be time to replace the tube.

7. Check Electrical Connections

Loose electrical connections can cause power fluctuations or even damage the machine’s components. Make sure all wires and connections are secure and free from corrosion.

Inspect Regularly: Check electrical connections and cables monthly to ensure there’s no fraying, corrosion, or damage.

Avoid Power Surges: Use a voltage regulator or surge protector to prevent damage from electrical fluctuations.

8. Software and Firmware Updates

Keeping the machine’s software and firmware up-to-date is essential for accessing the latest features, bug fixes, and performance improvements.

Regular Updates: Check for updates from the manufacturer and apply them to the machine’s control software.

Backup Settings: Before updating, back up your machine settings and parameters to avoid losing crucial configurations.

Maintaining your acrylic CO2 laser cutting machine is essential for prolonging its life and ensuring optimal cutting performance. By following the maintenance tips above—such as cleaning the optics, aligning the laser, lubricating parts, and checking the cooling system—you’ll keep your machine running smoothly for years.

The MYounglaser CO2 laser machines are designed with high precision and quality components like Japan Shinano motors, self-cleaning guide rails, and robust cooling systems, ensuring reliability in every cut. For cutting-edge performance, trust MYounglaser for your acrylic cutting needs.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

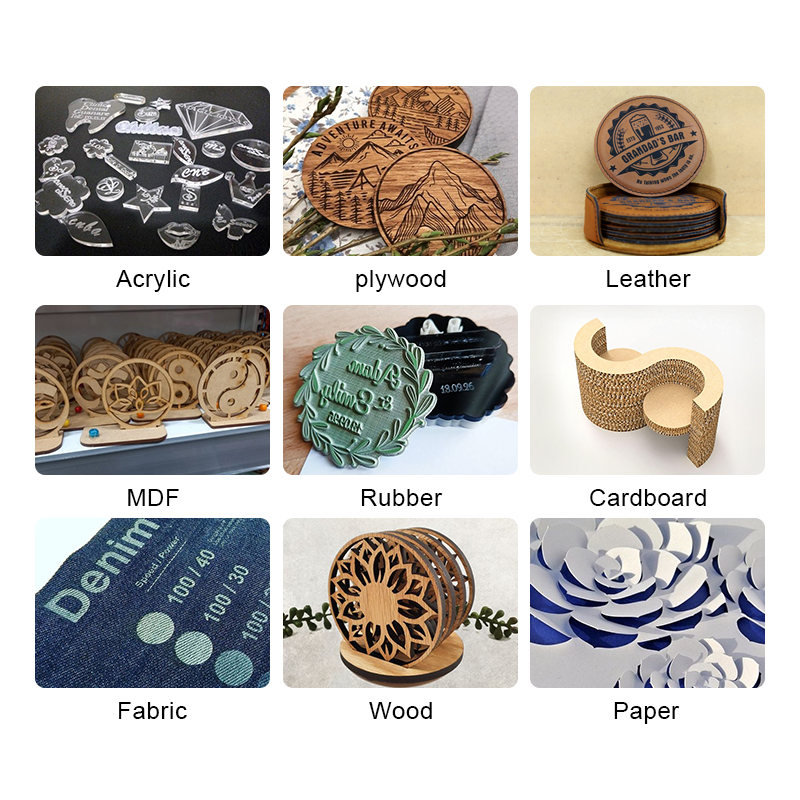

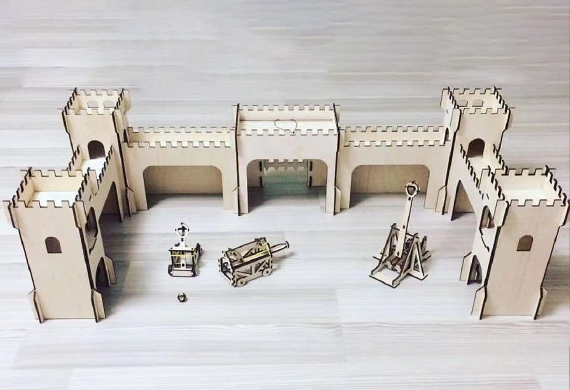

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.