INDUSTRIAL NEWS

How to Avoid Burn Marks on Acrylic with CO2 Lasers

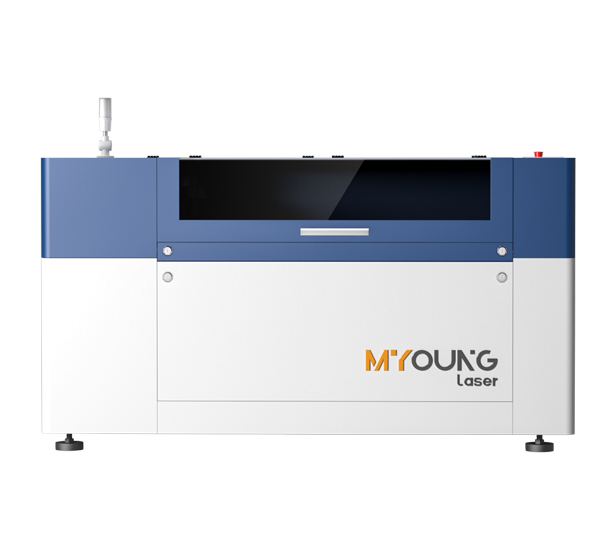

When working with a CO2 laser machine, burn marks on acrylic can be a common but manageable challenge. By understanding key techniques and settings, you can improve the quality of your cuts and achieve a clean finish. Here’s a guide on how to avoid burn marks on acrylic when using a CO2 laser, along with some recommended practices for MYounglaser machines and similar equipment.

1. Optimize Laser Settings

The settings of your laser machine, including power, speed, and focus, are critical for clean acrylic cuts.

- Laser Power: Lower the power settings to minimize heat exposure, as too much power can melt or burn the acrylic edges.

- Cutting Speed: Increase the cutting speed to reduce the laser’s time on each spot. Higher speeds can prevent overheating, which contributes to clean, burn-free cuts.

- Focus: Ensure the laser is correctly focused on the acrylic surface. Out-of-focus beams can increase the chance of burning as they disperse energy over a larger area.

2. Use an Air Assist System

An air assist system helps direct a stream of air over the cutting area, which keeps the acrylic surface cool and reduces burning. This is particularly useful for acrylic CO2 laser cutting machines to maintain precision and edge quality.

- Cooling Effect: The airflow cools down the cutting area, reducing the chances of melting or burning.

- Debris Removal: By blowing away debris and vaporized acrylic, air assist improves cutting clarity and prevents buildup that could otherwise lead to burns.

3. Choose the Right Type of Acrylic

Cast acrylic generally performs better than extruded acrylic in laser cutting, as it offers smoother, cleaner edges with less melting. If you’re working with extruded acrylic, you may need to make additional adjustments to avoid burning.

- Cast Acrylic: Results in cleaner cuts and is less prone to burns.

- Extruded Acrylic: May require lower power and higher speed settings to prevent melting and burning.

4. Consider Masking the Acrylic

Applying a protective masking layer on the acrylic surface can shield it from potential burns. Many users apply a paper or adhesive masking tape, which can absorb some of the heat generated during cutting.

- Protection Layer: Masking absorbs excess heat and prevents it from reaching the acrylic surface.

- Easy Removal: Masking tape can be peeled off post-cutting, leaving a clean surface with minimal residue.

5. Ensure Proper Ventilation and Exhaust System

Good ventilation helps remove heat and fumes generated during cutting, which can prevent burn marks on acrylic. Ensure your workspace has an effective exhaust system to maintain air quality and remove smoke and fumes.

- Exhaust System: Keeps the laser path clear and reduces smoke that can cause burns on the acrylic.

- Fume Extraction: Prevents acrylic residue buildup on the lens, which could affect cutting quality over time.

6. Fine-Tune the Machine’s Focusing Lens

Ensuring the focus lens is in optimal condition is essential for precision. A dirty or misaligned lens can cause overheating in certain areas, leading to burn marks.

- Clean Lens Regularly: Dust and residue on the lens can reduce beam quality, increasing the likelihood of burning.

- Check Alignment: Regularly align the lens to maintain a precise and focused laser beam on the acrylic surface.

7. Experiment with Different Cutting Techniques

Testing different approaches can also help you determine the best settings for clean cuts. Try varying power, speed, and even laser pulse settings to find the optimal configuration for your acrylic type.

- Trial Runs: Conduct sample cuts on small pieces to gauge the best settings without risking your primary material.

- Settings Adjustment: Gradually adjust settings based on observed results to refine cutting quality.

Choosing the Right Machine and Settings for Burn-Free Acrylic Cuts

Using these tips, you can achieve burn-free, polished acrylic cuts with a CO2 laser machine like the MYounglaser series. With precise power control, clean air assist, and attention to machine settings, cutting acrylic can become a smooth, professional process that consistently delivers high-quality results.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.