INDUSTRIAL NEWS

How to Cut Intricate Designs in Acrylic with CO2 Lasers

When it comes to precision and intricate designs, CO2 laser machines stand out as the tool of choice. Acrylic, as a laser-compatible material, allows designers to achieve smooth cuts, sharp angles, and complex patterns. But mastering the art of cutting intricate designs in acrylic involves knowing how to optimize your CO2 laser machine settings, material preparation, and handling techniques. Below, we dive into the key aspects of achieving flawless, intricate acrylic designs using a CO2 laser.

1. Choosing the Right Laser Power and Settings

The success of your design largely depends on choosing the correct power, speed, and frequency settings on your CO2 laser machine. For intricate designs:

- Power Level: Lower power settings (usually between 40-80W) are often preferred for intricate cuts, as they reduce the risk of overheating and melting the acrylic.

- Speed and Frequency: Higher speeds with moderate frequency (e.g., 500-1000 Hz) create clean cuts without excessive heat. Slow speeds may lead to more polished cuts, but when creating intricate shapes, avoid going too slow as it could cause unwanted melting around tight corners.

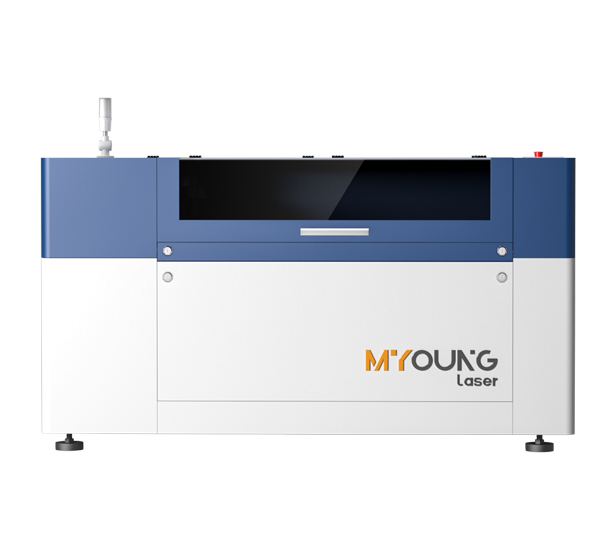

MYounglaser CO2 laser machines offer precise control over these settings, allowing you to adjust each parameter to match the complexity of your design and the acrylic’s thickness.

2. Material Selection and Preparation

Choosing Acrylic Type:

- Cast Acrylic is generally more suitable for laser cutting intricate designs than extruded acrylic. It cuts cleaner, produces a frosted edge, and is less likely to produce debris or irregular melting.

- Thickness: Thinner acrylic sheets (around 3-5mm) are easier to work with when designing intricate patterns, as they allow the laser to move more smoothly without deep cutting requirements.

Cleaning and Setup:

- Always clean the surface of the acrylic before cutting to remove any dust or particles that could interfere with the laser’s precision.

- Place the acrylic flat on the machine bed, ensuring there are no warps or curves. Using adhesive tape or a vacuum table can help stabilize the material and prevent shifting during the cutting process.

3. Design Preparation in Software

CO2 laser machines rely on vector files to guide cutting paths. For intricate designs, software choices are key:

- Choose Suitable Design Software: Programs like Adobe Illustrator or CorelDRAW are excellent for creating detailed vector designs. Ensure the vector paths are smooth to prevent the laser from hesitating or jumping during the cut.

- Optimize File Settings: Simplify paths where possible without compromising detail, as this minimizes the chances of the laser overlapping lines or doubling cuts. Set line thicknesses appropriately, ensuring they’re fine enough to capture detail but not so fine that the laser misinterprets them.

- Small Gap Adjustments: Make sure there’s a small allowance in designs with interlocking parts, especially when making intricate engravings or cutouts.

4. Test and Adjust Before Final Cutting

It’s beneficial to perform a few test cuts on a small acrylic sample before proceeding with your final piece:

- Trial Cuts on Scrap Material: Use a piece of scrap acrylic to test your settings. This helps identify any adjustments needed in speed or power.

- Evaluate Cut Quality: Check the cut quality after each test. If the edges are too rough, decrease the power or increase speed. If the cut doesn’t go through, slightly raise the power level.

5. Cutting Techniques and Machine Care

Optimized Pathing: Arrange your design to minimize unnecessary laser travel. This not only speeds up production but also reduces the risk of heat buildup around intricate areas. Use software to optimize the cutting path for efficiency.

Cooling System: Overheating is a common issue when cutting intricate designs. Ensure that your CO2 laser machine’s cooling system is functioning correctly, as this prevents overheating and keeps your cuts smooth. MYounglaser CO2 laser machines are equipped with advanced cooling systems that maintain optimal temperature during high-precision tasks.

Air Assist: The air assist function helps remove debris and prevents the laser from igniting small acrylic particles, which is particularly useful for fine, detailed work.

6. Finishing and Polishing

After cutting, you may notice minor imperfections or melted edges. Simple finishing steps can help refine the final product:

- Edge Polishing: Use a polishing solution or a polishing wheel to smooth any rough or slightly melted edges on your acrylic.

- Cleaning: Wipe down the surface to remove any residual dust or debris from the cutting process, ensuring a clean final product.

Why Choose MYounglaser CO2 Laser Machines?

MYounglaser’s CO2 laser machines are designed with intricate acrylic designs in mind. With precise power control, efficient cooling, and reliable performance, MYounglaser machines offer versatility for both beginner and expert users. These machines are ideal for producing professional-quality acrylic cuts while reducing the risk of common issues like melting or debris accumulation.

Start your intricate acrylic design journey with an MYounglaser CO2 laser machine, and experience unparalleled precision and control. Ready to upgrade your workshop? Contact us today for more information!

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

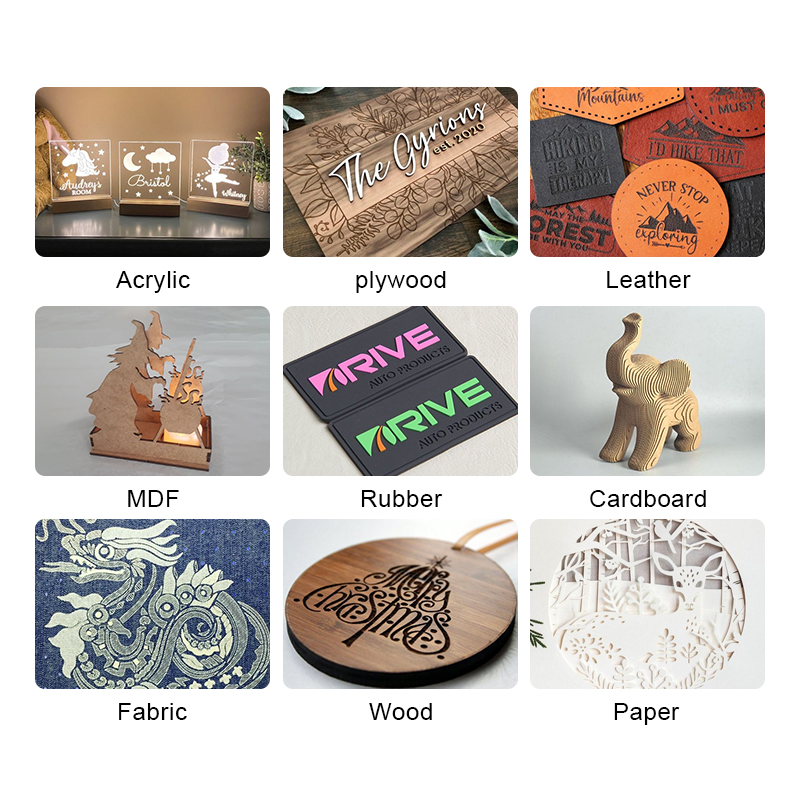

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.