INDUSTRIAL NEWS

Laser-Cut Acrylic Trophies: Design and Production

Using CO2 laser machines to create acrylic trophies is a fantastic way to produce professional, custom awards that are both durable and visually appealing. Laser-cutting acrylic enables precision and allows for detailed designs, making it an ideal choice for creating trophies of all shapes and sizes. Here’s a look at the design and production process, along with considerations for making the most out of CO2 laser cutting technology.

1. Designing Acrylic Trophies for Laser Cutting

- Choosing the Right Acrylic: Start by selecting high-quality cast acrylic, which cuts cleanly with CO2 laser machines and produces polished, smooth edges. This type of acrylic is preferred for trophies due to its durability and clarity.

- Customizable Shape and Design: Laser cutting allows for limitless design possibilities. Whether the trophy includes sharp angles, intricate shapes, or detailed engravings, CO2 laser machines make it easy to achieve precise and clean designs. Programs like Adobe Illustrator, CorelDRAW, and LightBurn are excellent tools for preparing intricate vector files compatible with CO2 laser machines.

- Size and Thickness: Decide on the appropriate thickness based on the trophy’s size and intended sturdiness. A thickness of 6-10mm is commonly used for most acrylic trophies.

2. Preparing for Production with CO2 Laser Machines

- Setting Laser Parameters: CO2 laser machines allow you to adjust speed, power, and frequency for clean cuts and engraving. For acrylic, use moderate power settings with lower speeds to achieve a smooth edge without burning.

- Engraving Details: CO2 laser machines are exceptional for adding intricate details and personalization to trophies. This includes names, dates, and logos. Ensuring the machine’s focus is precise and using a lower power setting will produce sharper, more detailed engravings without damaging the surface.

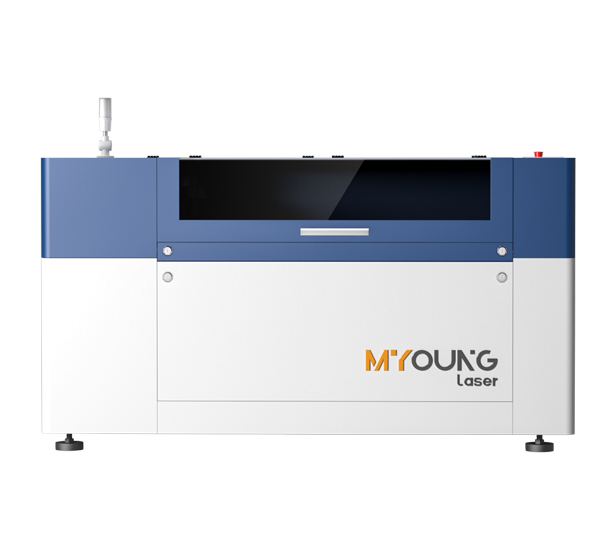

- Machine Calibration: Regular calibration is key to achieving consistent quality in acrylic cutting and engraving. Machines from MYounglaser are known for their durability and precision, and routine maintenance helps keep them performing at their best.

3. Producing Acrylic Trophies with CO2 Lasers

- Cutting the Shape: Begin by cutting out the shape of the trophy according to your design file. CO2 laser machines work quickly and can cut even complex shapes with high accuracy. Consider using an air assist attachment, which helps blow away debris and reduces the risk of burning on the edges.

- Polishing and Assembling: The edges of laser-cut acrylic are typically smooth and polished, but for an extra glossy finish, consider flame polishing. Once cut and engraved, assemble any additional pieces or stands to complete the trophy.

- Quality Check: Inspect the final product for clarity and edge quality. Any unwanted debris can be removed using a gentle cleaner to ensure a pristine finish.

4. Benefits of Using CO2 Laser Machines for Trophy Production

- Precision and Quality: CO2 laser machines, especially those by MYounglaser, are renowned for their precision, enabling detailed designs and clean cuts that are perfect for trophy production.

- Efficiency: Using a CO2 laser machine is faster than traditional cutting methods and allows for quick adjustments between projects. For large orders, this efficiency makes CO2 laser cutting a highly cost-effective option.

- Customization: The ease of programming custom designs means that each trophy can be uniquely tailored, adding value and a personal touch for recipients.

Creating laser-cut acrylic trophies with a CO2 laser machine is an efficient way to produce high-quality, visually appealing awards. With the right design software, quality acrylic, and a reliable CO2 laser machine like those offered by MYounglaser, you can bring any trophy design to life. Whether for sports events, corporate awards, or personal achievements, CO2 laser cutting technology provides a professional edge to trophy making.

Ready to Speak with One of Our Experts?

Getting started on any project can be daunting. Let us handle the technicalities so you can focus on bringing your designs to life.

Open the box; pull out your machine; and get to work. Whether you’re engraving on wood, leather, acrylic, or metal, just let us know your materials of choice, and we’ll find the perfect machine for your needs.

If you’re ready to upgrade your equipment, elevate your business, or simply unleash your creativity, we’re here to assist.

At Foshan Myoung Laser Technology Co., Ltd., established in 2012, we pride ourselves on integrating R&D, manufacturing, sales, and service to deliver top-notch laser solutions. Our range includes laser cutting machines, laser welding machines, laser marking machines, and industry-specific and automated laser equipment.

Got questions? Comments? Curious about our cutting-edge laser technology? Schedule a call with us today. We actually answer our phones and are here to help you every step of the way.