INDUSTRIAL NEWS

How to Select the Right Acrylic for Your CO2 Laser Cutting Machine

Choosing the right acrylic for your CO2 laser machine is essential for achieving optimal results in laser cutting and engraving. Acrylic is a popular material due to its versatility, transparency, and clean finish when cut with a laser. However, not all acrylic types are the same, and understanding which one is suitable for your project can make a significant difference in quality, speed, and overall outcome.

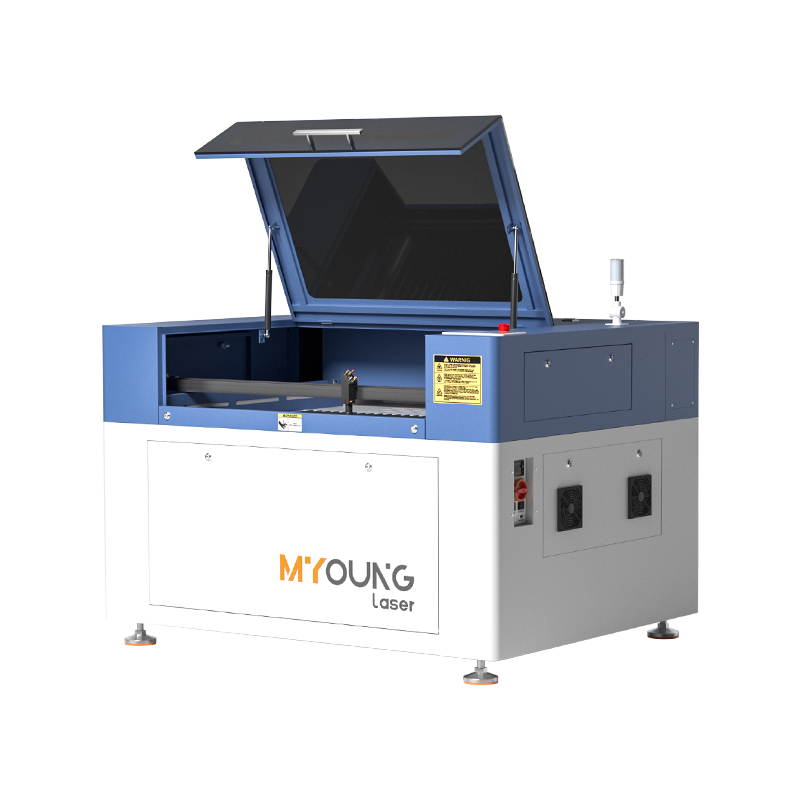

In this guide, we’ll explore the key factors to consider when selecting the right acrylic for your MYounglaser CO2 laser cutting machine.

1. Cast Acrylic vs. Extruded Acrylic

The first decision when choosing acrylic is deciding between cast acrylic and extruded acrylic. These two types behave very differently during the laser cutting process.

- Cast Acrylic: Cast acrylic is the preferred option for most CO2 laser machine users because it cuts and engraves beautifully. When engraved, cast acrylic produces a frosted effect that makes it ideal for signage, awards, and other decorative applications.

- Extruded Acrylic: While extruded acrylic is cheaper and more consistent in thickness, it doesn’t engrave as well as cast acrylic. Engraving extruded acrylic often results in a smoother finish with less contrast. However, for projects requiring simple cutting rather than engraving, extruded acrylic can still be a good option.

Recommendation: For detailed engraving and high-quality cuts, always choose cast acrylic.

2. Thickness of the Acrylic

The thickness of the acrylic affects not only how it cuts but also how much laser power is required.

- Thin Sheets (1-3mm): Thinner acrylic sheets are ideal for intricate designs, signage, and lightweight objects. They require less power and produce faster cuts. Thin sheets are typically used for small displays, ornaments, and creative projects.

- Thicker Sheets (4-10mm): For structural pieces such as furniture or larger signs, thicker acrylic sheets are preferred. Cutting thicker acrylic requires higher power settings and slower speeds to achieve a smooth, polished edge.

Recommendation: Match the thickness of the acrylic to the complexity and size of your project. A higher wattage CO2 laser machine from MYounglaser can handle thicker materials with ease.

3. Acrylic Colors and Finishes

Acrylic is available in various colors and finishes, allowing for creativity in your laser-cut designs.

Clear Acrylic: The most common and versatile choice, clear acrylic is ideal for projects requiring transparency, such as displays and protective covers. It cuts well and is easy to engrave, maintaining its clarity.

Colored and Frosted Acrylic: Colored acrylic is excellent for making signage, awards, and other creative projects that need a pop of color. Frosted acrylic provides a matte finish, which is perfect for projects that need to diffuse light, such as LED-lit displays.

Recommendation: Choose clear acrylic for its versatility, but don’t hesitate to explore colored or frosted acrylic for projects that demand a unique aesthetic.

4. Size of the Acrylic Sheets

The size of the acrylic sheet you need depends on the dimensions of the work area of your CO2 laser machine.

- Work Area: The MYounglaser Dura series offers machines with varying workspaces, from 900x600mm for the Dura 9 to 1600x1000mm for the Dura 16. Ensure that your acrylic sheet size matches or is smaller than the laser machine’s cutting area to avoid needing multiple cuts or repositioning during the process.

Recommendation: Always match the acrylic sheet size to the work area of your CO2 laser machine to maximize efficiency.

5. Laser Power and Settings

The laser power required for cutting acrylic depends on the material’s thickness and the desired finish.

Low Power (80W-150W): This power range is suitable for cutting and engraving thin sheets of acrylic (1-5mm) with precision.

Higher Power (200W-300W): For cutting thicker acrylic, machines like the Dura 13 or Dura 16 are equipped to handle materials up to 10mm in thickness without sacrificing speed or quality.

Recommendation: Adjust your laser settings based on acrylic thickness to ensure a smooth finish without excessive heat or charring.

Choosing the right acrylic for your CO2 laser machine depends on the type, thickness, color, and size of the material. Whether you’re working on signage, creative projects, or industrial applications, the MYounglaser Dura series provides the precision and power necessary for both cast and extruded acrylic.

With features like high-quality control systems, Japan Shinano motors, and modular guide rails, MYounglaser CO2 laser machines ensure smooth operation and consistent results in every cut. Choose MYounglaser for your acrylic laser cutting needs and achieve professional-grade results every time!